Challenges of SCC in Fresh State

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

High Material Cost

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

One of the first challenges of SCC in its fresh state is the high material cost. What do you think contributes to this high cost?

Is it because SCC requires special additives and more cement?

Exactly! SCC needs increased amounts of cementitious materials and specific admixtures like plasticizers. This can add up significantly. How do you think that affects budgeting for projects?

It probably makes projects more expensive, which might restrict who can use it.

That's a vital point. Higher costs can limit applicability, especially for smaller projects. Let’s remember: SCC = Special Cost Challenges.

Mix Design Complexity

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let’s discuss mix design complexity. Why do you think SCC requires more complex mix designs?

Because it has to flow well without segregation, right?

Exactly! The balance of components needs to be precise. What do you think would happen if the proportions are off?

It might not flow properly or could segregate.

Correct! This complexity necessitates more testing and adjustments, leading to increased time and expense. Remember: Design = Demand for Precision.

Sensitivity to Variations

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

The third challenge we’ll discuss is sensitivity to variations in water content. What do you think happens if there’s too much or too little water in SCC?

It could segregate or might not flow well.

That's exactly right! Even minor changes can cause significant issues. Why do you think maintaining consistency is so crucial?

To ensure the quality and performance of the concrete?

Yes! That emphasizes the need for stringent control measures. Keep in mind: Sensitivity = Success or Setback.

Quality Control Demand

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Finally, let’s talk about the quality control demand for SCC. Why do you think frequent testing is so important?

To make sure it’s performing as expected, right?

Exactly! We need to monitor rheological properties closely. What kinds of tests do you think are necessary?

I guess slump flow tests and possibly some viscosity tests?

Correct! These tests ensure that the SCC maintains its characteristics throughout its application. Quality = Key to SCC Success.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The challenges faced by self-compacting concrete (SCC) in its fresh state primarily include high material costs due to the need for special admixtures and precise mix designs, sensitivity to variations in water content that can lead to segregation, and a demand for stringent quality control measures. These factors complicate the effective delivery and use of SCC in construction projects.

Detailed

Challenges of SCC in Fresh State

Self-Compacting Concrete (SCC) is a modern concrete technology that provides superior workability, eliminating the need for vibration. However, its application in the fresh state comes with unique challenges:

- High Material Cost: SCC often requires an increased amount of cementitious materials and specialized admixtures, which can lead to significantly higher overall material costs compared to traditional concrete mixes.

- Mix Design Complexity: The need for precise proportioning and rigorous testing increases the complexity of the mix design. Engineers must ensure that the right balance is achieved for optimal performance based on project specifications.

- Sensitivity to Variations: SCC is particularly sensitive to changes in water content. Even minor adjustments can adversely affect the material’s performance, leading to issues such as segregation and loss of flowability.

- Quality Control Demand: Maintaining quality control is paramount when working with SCC. Frequent rheological testing must be conducted on-site to ascertain that the concrete is meeting the required performance standards.

These challenges can hinder the widespread adoption of SCC despite its benefits, thus requiring careful consideration and management in construction applications.

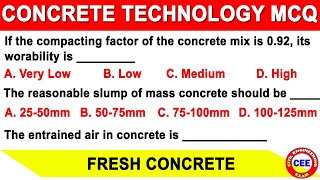

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

High Material Cost

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• High Material Cost: Requires increased use of cementitious materials and admixtures.

Detailed Explanation

Self-Compacting Concrete (SCC) is formulated using a higher quantity of cement and specialized admixtures compared to traditional concrete. While this enhancement improves workability and flow characteristics, it leads to a significant increase in material costs, making SCC more expensive to produce and use.

Examples & Analogies

Think of it like cooking a gourmet meal that requires high-quality ingredients—while the end result is delicious, the premium ingredients can make it much more expensive than a simple home-cooked dish.

Mix Design Complexity

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Mix Design Complexity: Needs precise proportioning and testing.

Detailed Explanation

Creating SCC requires a sophisticated mix design process. It involves carefully measuring and adjusting the proportions of various materials to achieve the desired flow properties and performance. This complexity necessitates extensive testing to ensure that the mix will perform as expected in practice.

Examples & Analogies

Consider it like baking a cake. You can't just throw ingredients together; you need to follow a precise recipe and adjust for your specific oven conditions. Just as baking too much or too little of one ingredient can ruin a cake, improper proportions in SCC can lead to poor performance.

Sensitivity to Variations

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Sensitivity to Variations: Small changes in water content can cause segregation or flow loss.

Detailed Explanation

SCC is sensitive to changes in its composition, especially the water content. Even a slight increase or decrease in water can result in segregation of aggregates—where heavier particles drift downward and lighter water rises, affecting the uniformity of the concrete and its ability to flow properly.

Examples & Analogies

Think of it as making a smoothie. If you add too much liquid, it may become too runny and lose its consistency, while too little liquid can make it lumpy and hard to blend. Similar issues arise in SCC when the water content isn’t properly balanced.

Quality Control Demand

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Quality Control Demand: Must conduct frequent rheological tests on-site.

Detailed Explanation

To ensure that SCC maintains its intended properties, frequent quality control is required on-site. This involves performing rheological tests to measure the flow behavior of the concrete. Continuous monitoring is crucial, as it helps to detect any deviations from the desired performance standards early in the process.

Examples & Analogies

It's like checking the temperature of a cake while it's baking. If you ignore the temperature and wait until the timer goes off, you might end up with a burnt cake. Similarly, regular testing in SCC helps ensure consistent quality and prevents issues before they escalate.

Key Concepts

-

High Material Cost: SCC incurs higher costs due to the use of special materials and admixtures.

-

Mix Design Complexity: The design process for SCC is intricate, requiring exact proportions.

-

Sensitivity to Variations: Small changes in water content can lead to serious performance issues.

-

Quality Control Demand: Frequent testing is necessary to maintain the integrity of SCC during its application.

Examples & Applications

An SCC mixture may require a specific combination of cement, silica fume, and superplasticizers to achieve the ideal flow characteristics.

In a case study where the water-cement ratio was not monitored closely, segregation occurred during transport, compromising the quality of the concrete.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

SCC can cost quite a bit, precision is what makes it fit.

Stories

Imagine a builder named Sam who found a magic concrete. It flowed beautifully but cost him dearly and needed special guidance to behave properly, showing the highs and lows of SCC.

Memory Tools

Remember 'MCSS' - Material Cost, Sensitivity, and Strict quality control for SCC.

Acronyms

SCC = Special Concrete Challenges.

Flash Cards

Glossary

- SelfCompacting Concrete (SCC)

A type of concrete that can flow and compact under its own weight without the need for vibration.

- Admixtures

Chemical additives used in concrete to alter its properties, such as workability and setting time.

- Mix Design

The process of defining the proportions of the materials used to make concrete, ensuring performance criteria are met.

- Segregation

The separation of the components of concrete during handling, leading to non-uniformity in the final product.

Reference links

Supplementary resources to enhance your learning experience.