Factors Affecting Setting Time

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Setting Time

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we'll discuss setting time, which is the period it takes for concrete to transition from a plastic to a hardened state. Can anyone tell me what influences this setting time?

Maybe the type of cement used?

Exactly! The type of cement can drastically change the setting time. For instance, rapid-hardening cement sets much quicker than ordinary Portland cement. Any thoughts on why this is?

Perhaps because it hydrates faster?

Right again! The hydration rate governs how quickly the concrete sets. Now, what about other factors?

I think temperature might play a role too.

Absolutely! High temperatures can speed up the setting process, while lower temperatures usually slow it down.

So, if it's a hot day, our concrete might set too fast?

Correct! That can create challenges on-site. Let's summarize: setting time can be affected by cement type and temperature.

Water-Cement Ratio's Impact

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s delve into the water-cement ratio. Who can tell me how it affects setting time?

A higher water-cement ratio might delay the setting?

That's precisely it! A high w/c ratio can slow down the hydration process, making the concrete less cohesive and prolonging the setting time.

So, if we want quicker setting, we need a lower water-cement ratio, right?

Exactly, but there's a balance to strike. Too little water can make the mix difficult to work with. Can anyone recall an example of how this influences practical work?

I remember a project where we had to ensure the right ratio to avoid issues when pouring.

Well said! Always remember to maintain the right balance for optimal results.

Role of Admixtures

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Lastly, let’s talk about admixtures. Who knows how they affect setting time?

Some make the concrete set faster, like accelerators, right?

Yes! Accelerators indeed speed up the setting time. On the contrary, what about retarders?

They would slow down the setting time?

Correct! Retarders can be especially useful in hot conditions. Can anyone think of why we might want to delay setting?

Maybe to allow for transportation or placement in larger projects?

Exactly! By modifying the setting time, we can better manage work on site. To summarize, admixtures play a crucial role in adjusting setting times based on project needs.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The section discusses the various elements that affect the setting time of concrete, such as the type of cement used, environmental temperature, the water-cement ratio, and the role of different admixtures like accelerators and retarders. Understanding these factors is crucial for managing concrete workability and strength.

Detailed

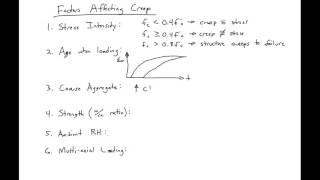

Factors Affecting Setting Time

Setting time is critical in determining when fresh concrete transitions to a hardened state. This section delineates the factors that significantly influence this timing:

1. Type of Cement

Different cements have varying setting times; for example, rapid-hardening cement sets quicker than ordinary Portland cement.

2. Temperature

Higher temperatures accelerate the setting process due to increased hydration rates. This can pose challenges for workers trying to manipulate the concrete before it sets.

3. Water-Cement Ratio

A higher water-cement (w/c) ratio generally delays setting because it slows down the hydration process and makes the concrete less cohesive.

4. Admixtures

Use of different admixtures can modify setting times. Accelerators speed up the setting while retarders prolong it. Using these additives can effectively tailor the concrete to specific project needs.

Understanding these factors is vital to ensure optimal workability and performance of concrete.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Type of Cement

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Type of cement (e.g., rapid hardening, ordinary Portland).

Detailed Explanation

The type of cement used can significantly influence the setting time of concrete. For instance, rapid hardening cement sets quicker than ordinary Portland cement. This means that if you're in a hurry and need your concrete to set more quickly for a project, you might opt for rapid hardening cement, though it can also be more expensive.

Examples & Analogies

Imagine baking a cake with a quick-mix recipe that tells you it will be ready in 20 minutes versus a traditional recipe that takes several hours. Similarly, using a rapid hardening cement is like the quick-mix recipe, allowing quicker results in construction.

Temperature Effects

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Temperature: Higher temperatures accelerate setting.

Detailed Explanation

Temperature plays a crucial role in determining how quickly concrete sets. Generally, warmer temperatures speed up the curing process, causing the concrete to harden faster. Conversely, in colder temperatures, the setting time can be significantly delayed. This is important to consider, especially when planning construction activities, as it can affect labor schedules and material handling.

Examples & Analogies

Think about how ice cubes melt faster in a warm room compared to one that's cold. Just as temperature affects ice, it also affects concrete; a warm day can make your concrete set quicker, while a cold day slows it down.

Water-Cement Ratio

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Water-cement ratio: High w/c ratio delays setting.

Detailed Explanation

The water-cement ratio is a critical factor affecting setting time. A higher water-cement ratio means more water relative to cement, which can significantly delay the setting process. This is because excess water needs to evaporate before the concrete can fully set and gain strength. Balancing this ratio is essential for optimal performance of concrete.

Examples & Analogies

Consider making a soup; if you add too much water, it takes longer to simmer and thicken. Similarly, too much water in concrete means it will take longer to set properly.

Use of Admixtures

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Admixtures: Accelerators decrease, retarders increase setting time.

Detailed Explanation

Admixtures are substances added to the concrete mix to enhance its properties. Accelerators are admixtures that speed up the setting time, which can be useful in cold weather or when quick curing is needed. On the other hand, retarders slow down the setting time, useful for hot weather conditions or when working with complex forms where delayed setting helps maintain workability.

Examples & Analogies

Imagine you're cooking pasta. If you add salt (like an accelerator), it might cook quicker under the right conditions. Conversely, if you turn down the heat (like using a retarder), the pasta takes longer to cook. Admixtures play a similar role in modifying how concrete sets.

Key Concepts

-

Type of Cement: Different cements have varying setting times which affect project scheduling.

-

Temperature: Higher temperatures accelerate the setting process.

-

Water-Cement Ratio: A higher ratio delays setting time due to a slower hydration process.

-

Admixtures: Can be used to control setting time effectively, allowing for flexibility on-site.

Examples & Applications

Using rapid hardening cement in cold weather constructions to achieve faster setting times despite lower temperatures.

Adding retarders in hot weather to maintain workability and avoid quick setting.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

When the sun is high, the cement sets swift, but in the chill, it gives a slow lift.

Stories

Imagine a race between two cement types, one rapid and the other slow; under the sun they pick up speed, while in the shade they take it slow. The choice you make affects how quickly your project will grow!

Memory Tools

Cement Types - RAPID: R (Rapid Hardening), A (Admixtures), P (Placement), I (Initial Setting), D (Duration of Workability).

Acronyms

SET - S (Setting Time), E (Environmental Conditions), T (Type of Cement).

Flash Cards

Glossary

- Setting Time

The duration required for concrete to transition from plastic (workable) to a hardened state.

- Cement Type

Different kinds of cement (e.g., rapid hardening, ordinary Portland) that influence the hydration rate and setting time.

- WaterCement Ratio

The ratio of water to cement in a concrete mix affecting its workability and setting time.

- Admixtures

Chemical additives that modify the properties of concrete, including setting time.

- Accelerators

Admixtures that speed up the setting process in concrete.

- Retarders

Admixtures that delay the setting time of concrete.

Reference links

Supplementary resources to enhance your learning experience.