Requirements for Pumpable Concrete

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Cohesiveness in Concrete

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we’re discussing one of the critical requirements for pumpable concrete: cohesiveness. Can anyone tell me what cohesiveness means in this context?

Is it how sticky or clump-like the concrete is?

Exactly! Cohesiveness refers to how well the concrete holds together. If it's too loose, the aggregates can separate. Keeping concrete cohesive helps prevent segregation during pumping.

So, what happens if it's not cohesive enough?

Great question! If it's not cohesive enough, we risk having uneven distribution of aggregates, which affects the strength of the concrete. Remember the acronym C.A.S.H - Cohesiveness, Aggregate distribution, Strength, Handling - it encompasses key factors when discussing concrete behavior.

Can we enhance cohesiveness?

Yes! This can be achieved through proper mix design and the use of certain admixtures, which brings us to our next topic.

Mortar Fraction & Lubrication

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s talk about the mortar fraction. Why do you think it’s crucial for pumping concrete?

Isn’t that part the cement and water mixture that helps the concrete flow?

Exactly right! The mortar fraction acts like a lubricant in the pipe—it helps concrete flow smoothly and reduces friction. If there's too little mortar, friction increases, and we could face a blockage.

So, how do we get the right mortar fraction?

It’s a balance! Use the right proportions of water, cement, and additives. Remember to consider flowability—a vital term to associate with the mortar fraction.

Aggregate Size and Admixtures

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s explore the importance of well-graded aggregates. What do you think is meant by 'well-graded'?

I think it means having a mix of different sizes of aggregates?

Spot on! Well-graded aggregates provide a denser packing and help reduce void spaces, leading to improved pumpability. The typical recommendation is that the maximum aggregate size is less than one-third the diameter of the pipeline. This way, they flow without clogging up the system.

What about those admixtures that were mentioned?

Admixtures, like plasticizers, are vital. They improve the workability of the concrete without adding more water. Remember the term P.A.W. - Plasticizers, Admixtures, Workability—keep that depth of understanding in mind when preparing concrete.

Common Issues in Pumping

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Finally, let’s discuss common problems encountered when pumping concrete. What do you think can go wrong?

Blockage can happen, right? Especially if the mix isn’t right.

Exactly! Blockages can occur due to improper mix or the segregation of aggregates. It's also important to maintain optimal pumping pressure, which adds to the coordination of the pumping process.

And what about bleeding during the pumping?

Yes, bleeding can create weak zones due to excess water at the surface. Open your minds to the relationship between mix design and pumpability. Now, let’s recap today's session about cohesiveness and the critical role of mortar fraction!

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

For fresh concrete to be pumpable, it must exhibit sufficient cohesiveness, a proper mortar fraction, well-graded aggregates, and the use of appropriate admixtures. Handling these factors ensures efficient and effective transportation of concrete to its final placement.

Detailed

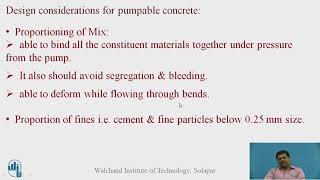

Requirements for Pumpable Concrete

To ensure effective pumping of fresh concrete over long distances or heights, several critical requirements must be met:

1. Cohesiveness: Concrete must have adequate cohesiveness to prevent segregation of aggregates.

2. Mortar Fraction: A proper mortar fraction is essential to lubricate the pumping pipes and facilitate smooth flow.

3. Well-graded Aggregates: Aggregate size must be well-graded, typically with a maximum aggregate size of less than one-third the diameter of the pumping pipes.

4. Admixtures: The use of admixtures such as plasticizers and viscosity-modifying agents can enhance pumpability by improving the flow characteristics and workability of the concrete.

These requirements are crucial as they directly influence the efficiency and effectiveness of the pumping process, ensuring that the concrete maintains its integrity and performance standards during transportation.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Cohesiveness

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Sufficient cohesiveness to avoid segregation.

Detailed Explanation

Cohesiveness in concrete refers to how well the concrete components stick together. When a concrete mix has sufficient cohesiveness, it prevents the heavier aggregate particles from separating from the cement paste during pumping, which can lead to uneven mixtures and weak areas. This characteristic is essential for maintaining the integrity of the concrete as it moves through pipes.

Examples & Analogies

Think of cohesiveness like a well-mixed salad dressing. If oil separates from vinegar, the salad won't taste right. Similarly, if the ingredients in concrete separate during pumping, the final structure won't have the strength needed.

Mortar Fraction

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Proper mortar fraction to lubricate the pipe.

Detailed Explanation

The mortar fraction in concrete refers to the amount of fine material (like cement and sand) present to fill the gaps between the larger aggregates. This mortar acts like a lubricant in the pumping process. An adequate amount of mortar ensures that the concrete can flow smoothly through pipes without causing blockages or excessive wear on the pumping equipment.

Examples & Analogies

Imagine trying to push a thick smoothie through a straw. If it’s too chunky, it won't flow well. However, if you blend it properly with enough liquid, it glides through the straw easily. Similarly, the right mortar fraction helps concrete pump through pipes smoothly.

Aggregate Size and Grading

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Well-graded aggregate (maximum size typically < 1/3 of pipe diameter).

Detailed Explanation

Aggregate grading refers to the distribution of different sizes of aggregate particles within the concrete mix. For effective pumping, it is important that the maximum size of these aggregates is less than one-third the diameter of the pipe used for pumping. This ensures that the concrete can flow easily without getting stuck or causing blockages. Well-graded aggregates enhance the flow characteristics, making the mix more pumpable.

Examples & Analogies

Consider pouring beans through a funnel. If the beans are too large compared to the funnel's opening, they'll get stuck. If you use smaller beans or a mix of sizes that can fit through easily, the flow is smooth. This illustrates how well-graded aggregates support the pumping process.

Use of Admixtures

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Use of admixtures like plasticizers and viscosity-modifying agents.

Detailed Explanation

Admixtures are substances added to the concrete mix to modify its properties. Plasticizers are used to improve workability without adding more water, making it easier to pump. Viscosity-modifying agents help control the flow characteristics, ensuring that the concrete maintains a good consistency and doesn’t segregate during pumping. Using the right admixtures is crucial for achieving optimal pumpability, especially in complex construction scenarios.

Examples & Analogies

Think of plasticizers like a bit of oil in a frying pan. It allows food to slide around easily instead of sticking and burning. In the same way, admixtures help concrete move smoothly through the pump and along the pipeline.

Key Concepts

-

Cohesiveness: Essential for preventing segregation in pumped concrete.

-

Mortar Fraction: Aids in the smooth lubrication of the pumping system.

-

Well-Graded Aggregates: Reduces blockage by promoting better flow.

-

Admixtures: Modify properties of concrete, enhancing its pumpability.

Examples & Applications

Using plasticizers can significantly improve the workability of a concrete mix, allowing it to be pumped easily even through long distances.

Selecting well-graded aggregates for concrete ensures that there are fewer voids, making pumping more efficient.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Cohesive concrete is a must, for without it, chunks will rust!

Stories

Imagine a race car on a smooth track versus a rocky road. The smooth track allows the car to flow fast and efficiently, just like well-graded aggregates allow concrete to flow effortlessly through the pumping system.

Memory Tools

Remember 'CAMP' for Concrete requirements: Cohesiveness, Admixtures, Mortar, Pumpability.

Acronyms

Use the acronym 'CAMP' to remember the key requirements

Cohesiveness

Aggregate grading

Mortar fraction

and Pumpability.

Flash Cards

Glossary

- Cohesiveness

The ability of concrete to hold its ingredients together, preventing segregation.

- Mortar Fraction

The part of the concrete mix that consists of cement and water, crucial for lubrication during pumping.

- WellGraded Aggregates

A mix of aggregate particle sizes that promotes dense packing and reduces voids.

- Admixtures

Substances added to concrete to modify its properties, such as plasticizers that improve workability.

- Pumpability

The ability of concrete to be easily pumped through pipes without obstruction.

Reference links

Supplementary resources to enhance your learning experience.