Hot and Cold Weather Concreting – Fresh State Behavior

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Hot Weather Concreting

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we'll discuss how hot weather impacts concrete while it's still fresh. Can anyone tell me why hot weather can negatively affect concrete?

I think it might cause it to set too quickly?

Exactly! Hot weather can lead to rapid evaporation, which in turn can cause plastic shrinkage cracks. This can make it challenging to handle concrete effectively.

What can we do about that?

Great question! Some methods include using chilled water in the mix and scheduling pours during cooler parts of the day. Remember the acronym CLIP: Chilled water, Lower temps, Ice, and Protection measures.

What about using retarders? Do they really help?

Yes, they do! Retarders slow down the setting time, which can be extremely helpful in managing fresh concrete in hot weather.

So protecting the concrete as it hardens is important too?

Absolutely! We must ensure that the concrete remains moist and protected from high temperatures and sunlight to avoid premature evaporation.

In summary, to handle hot weather concrete effectively, we should use chilled materials, limit hydration loss, and protect the mix in cooler periods.

Cold Weather Concreting

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let's talk about how cold weather affects concrete. What are some challenges we might face?

Water could freeze in the mix, right?

Correct! Freezing water can expand and damage the concrete structure. What solutions can we utilize to combat this?

We could heat the water and aggregates before mixing them!

Yes! Heating them ensures we maintain an optimal working temperature. Additionally, we can add accelerators to the mix to promote faster setting.

And what about once it's poured?

Great question! We need to protect it with insulated blankets to prevent it from freezing after placement. Avoiding frozen ground is also crucial.

Is there a risk with using too many accelerators?

That's a valid concern. While accelerators help, overuse can lead to reduced strength. It's all about striking a balance.

To summarize, in cold weather concreting, make sure to heat materials, use accelerators wisely, protect the concrete, and avoid frozen ground conditions.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The section details how extreme temperatures can affect fresh concrete, leading to issues like rapid evaporation and freezing. It also provides strategies for handling concrete in varying weather conditions, highlighting methods for both hot and cold weather concreting.

Detailed

Hot and Cold Weather Concreting – Fresh State Behavior

In this section, we explore the critical impacts of extreme weather conditions on the fresh state behavior of concrete, including the issues faced during hot and cold weather conditions and practical measures to counteract them.

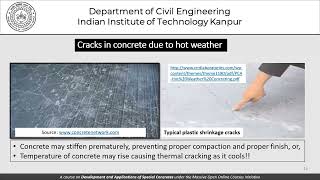

1. Hot Weather Concreting

Hot weather can lead to several significant problems in the handling of fresh concrete, including:

- Rapid Evaporation: This results in plastic shrinkage cracking as moisture is lost before the concrete can properly set.

- Shortened Setting Time: Increased temperatures can accelerate setting times, complicating the mixing and horizontal placement of concrete.

- Increased Water Demand: Higher temperatures necessitate more water in the concrete mix, which can dilute strength and durability.

To mitigate these effects, several measures are recommended:

- Using Chilled Water or Ice: Incorporating chilled water or ice into the concrete mix helps reduce the initial temperature of the mix.

- Scheduling Pours During Cooler Hours: Placing concrete during early morning or late evening hours can minimize temperature effects.

- Using Retarders and Hydration Stabilizers: These additives can help slow down the setting and evaporation rates, maintaining workability.

- Shading Aggregates and Formwork: Keeping materials cool is a simple yet effective approach to counteracting heat impacts.

2. Cold Weather Concreting

Cold weather presents its own challenges:

- Freezing of the Mix: Water can freeze and expand, leading to the deterioration of the concrete paste structure.

- Very Slow Hydration Rate: Cold temperatures can significantly hinder the hydration process, delaying the hardening of the mix.

To combat these issues, several strategies may be adopted:

- Heating Mixing Water and Aggregates: This ensures that the concrete is poured at optimal temperatures, promoting hydration.

- Using Accelerators: Admixtures like calcium chloride help speed up the setting process, reducing potential cold weather issues.

- Protecting Freshly Placed Concrete: Insulated blankets can safeguard newly poured concrete from freezing conditions.

- Avoiding Frozen Subgrade: Ensuring that the ground beneath the concrete is free from ice and snow prevents underlying freezing effects.

Overall, understanding the behavior of fresh concrete in varying weather conditions is essential for ensuring its performance and durability in the hardened state.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Hot Weather Concreting Issues

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Issues:

- Rapid evaporation leads to plastic shrinkage cracks.

- Shortened setting time causes handling difficulties.

- Increased water demand reduces strength.

Detailed Explanation

In hot weather, several challenges arise when working with fresh concrete. First, high temperatures can cause the water in the mix to evaporate quickly, which might lead to cracks on the surface known as plastic shrinkage cracks. Secondly, when the concrete sets too quickly, it may become difficult to work with, resulting in complications during the placement and finishing processes. Lastly, the demand for water in the mix increases in hot conditions, yet if this is not carefully managed, it can weaken the concrete’s overall strength.

Examples & Analogies

Imagine making a custard on a hot day. If the mixture heats up too quickly, the custard could set before you're ready to pour it into the mold, resulting in lumps. Similarly, hot weather can cause fresh concrete to start setting too fast for a smooth finish.

Hot Weather Concreting Measures

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Measures:

- Use chilled water or ice in mix.

- Schedule pours during cooler hours.

- Use retarders and hydration stabilizers.

- Shade aggregates and formwork.

Detailed Explanation

To mitigate the problems associated with hot weather concreting, several effective strategies can be employed. First, using chilled water or adding ice to the concrete mix helps keep the temperature down. It's also beneficial to plan concrete pours during the cooler parts of the day, such as early morning or late afternoon. Furthermore, incorporating retarders into the mix can extend the setting time, allowing for easier handling. Finally, shading the aggregates and formwork from direct sunlight can prevent them from heating up, thus reducing the chances of rapid evaporation.

Examples & Analogies

Consider how you might keep ice for a picnic. To keep the ice from melting too quickly in the sun, you place it in a cooler, use ice packs, and avoid opening the cooler constantly. Similarly, in concrete work, managing temperature with chilled materials and proper planning can ensure better results.

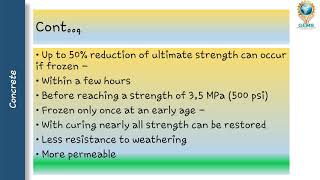

Cold Weather Concreting Issues

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Issues:

- Freezing water expands and damages the paste structure.

- Very slow hydration rate.

Detailed Explanation

Cold weather presents its own set of challenges for fresh concrete. When the temperature drops, there is a risk that any water in the concrete mix may freeze. This freezing can cause the water to expand, which can ultimately damage the structure of the concrete paste, leading to weaknesses. Additionally, the process of hydration—the chemical reaction that allows concrete to harden—occurs at a much slower rate in colder temperatures. This means the concrete takes longer to reach its desired strength, which can delay construction activities.

Examples & Analogies

Think of how a glass of water becomes ice in the freezer. If you fill a glass too full, the water will expand as it freezes, potentially breaking the glass. Similarly, water in concrete can expand when it freezes, causing damage. The slower process of ice forming relates to how hydration slows down in cold conditions.

Cold Weather Concreting Measures

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Measures:

- Heat mixing water and aggregates.

- Use accelerators (e.g., calcium chloride).

- Protect freshly placed concrete with insulated blankets.

- Avoid frozen subgrade placement.

Detailed Explanation

To combat the issues related to cold weather, several measures can be undertaken to ensure fresh concrete is adequately protected. One effective approach is to heat the mixing water and aggregates before adding them to the mix, which helps maintain a suitable temperature. Additionally, using chemical accelerators, like calcium chloride, speeds up setting and hydration, making it easier for the concrete to gain strength in cold conditions. Covering the freshly poured concrete with insulated blankets helps retain heat and moisture, while also preventing freezing from occurring. Lastly, it is crucial to avoid placing concrete on frozen ground, as this can adversely affect bonding and stability.

Examples & Analogies

Consider bundling up in layers of warm clothing on a chilly day to stay warm. Similarly, using heated materials and insulated coverings helps keep the concrete warm and allows it to cure properly, much like staying warm in cold weather helps prevent frostbite.

Key Concepts

-

Hot Weather: Concreting challenges include rapid evaporation, shortened setting time, and increased water demand.

-

Cold Weather: Issues relate to freezing water, delayed hydration, and protective measures.

-

Retarders: Chemical additives that enhance workability during hot conditions by slowing setting.

-

Accelerators: Used in cold weather to speed up setting and hardening of concrete.

Examples & Applications

Using chilled water in the concrete mix during hot weather to maintain workability and prevent cracks.

Employing insulated blankets over concrete during cold weather to prevent freezing and ensure proper curing.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Hot days call for chilled ice, to keep our concrete cold and nice.

Stories

Once in a hot summer, a concrete mix was prepared. Without ice or shade, it swiftly cracked, and the workers feared it was all for naught. They learned to chill and shade their mix for future pours to come.

Memory Tools

Remember 'HANDS' for Hot Weather: Heat reduction, Afternoon pours, No high water, Draining water, Shade your mix.

Acronyms

COLD FOR Cold Weather

Covers

Optimized temp

Liquid heaters

Downtime management.

Flash Cards

Glossary

- Hot Weather Concreting

Techniques and measures used to enhance the performance of concrete when placed in elevated temperature conditions.

- Cold Weather Concreting

Strategies implemented to manage the challenges posed by low temperature conditions during the handling of fresh concrete.

- Plastic Shrinkage Cracks

Cracks that occur in the surface of freshly placed concrete due to rapid evaporation of surface moisture.

- Hydration Rate

The rate at which water in the concrete mix reacts with cement, leading to setting and hardening.

- Retarders

Admixtures that slow down the setting time of concrete, useful in warm weather to prolong workability.

- Accelerators

Chemicals added to concrete to speed up the setting and hardening process, particularly useful in cold weather.

- Insulated Blankets

Materials used to cover freshly placed concrete to protect it from low temperatures and freezing conditions.

- Chilled Water

Water that is cooled before addition to a concrete mix, aimed at reducing the mix temperature.

- Frozen Subgrade

Ground that is frozen and can adversely affect the curing of concrete when it is placed upon it.

Reference links

Supplementary resources to enhance your learning experience.

- Hot Weather Concreting Effects

- Cold Weather Concreting Guidelines

- Understanding Plastic Shrinkage Cracking

- Retarding Admixtures in Concrete

- Best Practices for Cold Weather Concreting

- Curing and Winter Protection

- Practical Guide to Hot Weather Concreting

- Impact of Temperature on Concrete

- Concrete Mixing and Temperature Management