GGBFS (Ground Granulated Blast Furnace Slag)

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to GGBFS

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, let's discuss Ground Granulated Blast Furnace Slag, or GGBFS. This material is a byproduct from steel production and can significantly enhance concrete properties. Can anyone tell me what it is primarily used for in concrete?

Is it used to improve the strength of concrete?

Good point! It does improve concrete strength, but one of its major benefits is enhancing pumpability. This makes concrete easier to transport and place in challenging sites.

How does it actually improve pumpability?

GGBFS modifies the rheological properties of concrete. It helps create a more fluid mix which reduces friction during pumping. Remember the acronym 'GGBFS'—*G*reatly *G*ains *B*etter *F*lowing in *S*tructures!

What about the setting time? I heard it slows it down.

Exactly! GGBFS can slow the setting times in cold conditions. It’s essential to consider this while designing your mix. Always account for temperature effects!

So, if we use GGBFS, we need to plan for longer setting times?

Yes! Adequate planning is key. In summary, GGBFS improves pumpability and workability but requires careful attention regarding setting time.

Applications and considerations of GGBFS

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's dive into how GGBFS is applied in real-world scenarios. Can anyone think of a situation where it might be beneficial?

Maybe in high-rise buildings? They require a lot of concrete!

Yes! In high-rise construction or congested reinforcement areas, GGBFS helps in achieving better flowability, ensuring the concrete fills all spaces without leaving voids.

Are there specific types of projects where we should avoid using it?

That’s a great question! Projects that require rapid setting or high early strength might need to use GGBFS with caution or consider other additives alongside it.

So it's all about balance, right? Finding the right mix?

Exactly! It's about achieving a balanced mix design. Always assess your project's needs against GGBFS's characteristics. It’s versatile but not always the solution.

Could you remind us of how GGBFS helps in sustainability?

Certainly! GGBFS is a recycled material that reduces the amount of Portland cement needed, helping to minimize carbon emissions. It embodies the principles of sustainable construction. Great job summarizing that!

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Ground Granulated Blast Furnace Slag (GGBFS) is recognized for its ability to improve the workability and durability of concrete. While it enhances pumpability, it can slow down the setting time in colder conditions, requiring careful mix design consideration.

Detailed

GGBFS (Ground Granulated Blast Furnace Slag)

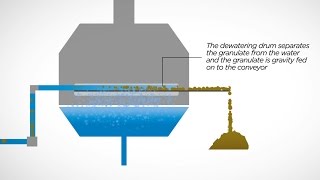

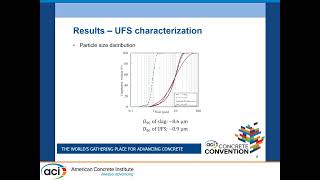

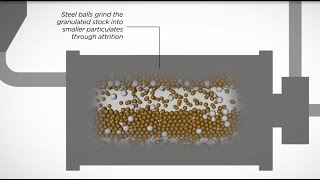

Ground Granulated Blast Furnace Slag (GGBFS) is a byproduct of the steel-making process, where iron is extracted from iron ore in a blast furnace. It is produced by rapidly cooling molten slag with water, resulting in a glassy material that can be used as a supplementary cementitious material in concrete. GGBFS is primarily used to enhance the performance characteristics of concrete. The incorporation of GGBFS in concrete mixes can improve pumpability, which is essential for projects involving complicated or congested placements.

Key Characteristics:

- Improved Pumpability: GGBFS modifies the rheological properties of concrete, making it easier to transport and place, especially in intricate formwork.

- Setting Time: GGBFS has a tendency to slow down the setting times of concrete mixes, particularly in colder weather, which can lead to challenges during construction unless proper measures are taken.

Understanding the role of GGBFS in concrete mix designs is vital for optimizing the performance while considering the environmental benefits due to its recycled nature as a cement substitute.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Improves Pumpability

Chapter 1 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Improves pumpability.

Detailed Explanation

GGBFS, or Ground Granulated Blast Furnace Slag, is a supplementary cementitious material that enhances the flow properties of fresh concrete. When it is incorporated into the concrete mix, GGBFS can help in making the concrete more fluid and easier to pump through pipelines. This is particularly beneficial for large-scale construction projects where concrete needs to be transported over long distances or through complex forms.

Examples & Analogies

Think of GGBFS like adding a small amount of oil to a thick smoothie. Just as oil helps the smoothie flow smoothly through a straw, GGBFS helps concrete flow easily through pumps, making the job of pouring concrete much easier and more efficient.

Slower Setting in Cold Weather

Chapter 2 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Slower setting in cold weather.

Detailed Explanation

One characteristic of GGBFS is its influence on the setting time of concrete, especially in cold weather conditions. When temperatures drop, the hydration reaction in concrete slows down, and while GGBFS can help maintain workability, it may also mean that the concrete takes longer to set. This is an important consideration for construction scheduling during chilly months, as workers may need to allow more time for the concrete to harden before beginning further work.

Examples & Analogies

Imagine trying to cook a pot of soup on a cold day. The cold temperature might slow down the cooking process, meaning the soup takes longer to heat up compared to a warm kitchen. Similarly, when concrete mixed with GGBFS is placed in cold weather, it sets more slowly than other mixtures, requiring careful planning and timing from the construction crew.

Key Concepts

-

GGBFS enhances pumpability: It significantly improves the flowability of concrete, essential for complex placements.

-

Slower setting time: GGBFS can lead to extended setting times, particularly relevant in cooler environments.

-

Sustainability benefits: Using GGBFS helps reduce carbon footprints by minimizing the need for Portland cement.

Examples & Applications

Using GGBFS in high-rise construction helps to ensure that concrete reaches all corners of complex formwork without leaving voids.

In cold weather conditions, using GGBFS may delay setting time but can also improve long-term durability of concrete when designed properly.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

In the cold, it slows down, but makes a pumpable town!

Stories

Imagine a construction site where workers struggle to get heavy concrete to rise in the air. Then, they discover GGBFS, which helps their concrete flow smoothly into all corners without hesitation.

Memory Tools

To remember GGBFS: Greatly Gains Better Flow for Structures.

Acronyms

GGBFS

Ground - Granulated - Blast - Furnace - Slag.

Flash Cards

Glossary

- GGBFS

Ground Granulated Blast Furnace Slag, a supplementary cementitious material that improves concrete's pumpability and durability.

- Rheology

The branch of physics that deals with the flow of matter, important for understanding the flow behavior of fresh concrete.

- Pumpability

The ability of concrete to be pumped through pipes without segregation or blockage.

Reference links

Supplementary resources to enhance your learning experience.