Cold Joints

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Understanding Cold Joints

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're discussing cold joints in concrete. Who can explain what a cold joint is?

A cold joint occurs when you pour new concrete against concrete that has already hardened.

Exactly! And what happens if there's a delay in placing the new concrete?

The new concrete doesn't bond well with the hardened concrete, leaving a weak area.

That's right. We call that weak interface a cold joint. Can anyone think of some consequences of cold joints?

It could lead to cracking or structural failure, right?

Yes, very good! Cold joints can substantially weaken a structure. As a review, what are the essential reasons we need to be aware of cold joints? Let's sum it up.

Causes of Cold Joints

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Can anyone tell me what typically causes cold joints?

I think it's when there’s a significant delay after the initial set.

That's correct! Delays exceeding the initial setting time of concrete are the main cause. What do you think happens if we use retarding admixtures?

It might help delay the setting time to prevent cold joints.

Exactly! Retarding admixtures can give us more time to place concrete. Any other measures to consider?

We should also minimize delays when pouring mixed concrete.

Great point! Minimizing delays during the pour is critical. Let's recap what we learned about the causes of cold joints.

Prevention of Cold Joints

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

How can we prevent cold joints during a concrete pour?

Using proper timing and making sure we place the concrete as soon as possible!

Right! Timing is crucial. Can anyone share a strategy that could help speed up concrete placement?

Maybe getting more workers on site can help!

Absolutely! More hands can help. Now let’s talk about re-tempering. Why should we be careful with that?

Because it can weaken the mix, right?

Exactly! Re-tempering should be done cautiously. Let’s summarize the strategies to prevent cold joints.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section discusses cold joints, which result from a delay exceeding the initial setting time, and their impact on the strength of concrete interfaces. Measures to minimize these effects, such as the use of retarding admixtures and maintaining timely concrete placement, are also highlighted.

Detailed

Cold Joints

Cold joints are a significant concern in concrete construction, arising when new concrete is poured against previously set concrete. When there is a delay in placing new concrete beyond its initial setting time, a cold joint is created, leading to a weak interface due to inadequate bonding between the two layers. This can result in compromised structural integrity and potential failure over time.

Key Points:

- Definition: A cold joint occurs when two layers of concrete, one hardened and one fresh, are placed together without adequate bonding.

- Causes: The primary cause of cold joints is delays in placing the concrete mixture, particularly when such delays exceed the initial setting time.

- Consequences: The major consequence of a cold joint is a weak interface, which can lead to structural vulnerabilities. This weak zone may crack or separate under stress, compromising the overall strength of the concrete structure.

- Prevention: To minimize the occurrence and effects of cold joints, it's important to use retarding admixtures effectively to prolong the setting time, reduce the delay between mixing and placing concrete, and carefully manage the sequencing of concrete pours. However, re-tempering, the act of cautiously adding water to adjust the mix, should be avoided unless strict quality control measures are in place.

Understanding and addressing cold joints is critical for ensuring the durability and stability of concrete structures.

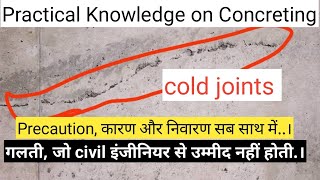

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Definition of Cold Joints

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Occur when new concrete is placed against hardened concrete.

Detailed Explanation

Cold joints happen when a fresh batch of concrete is poured against concrete that has already set. This can create a weak point in the structure, as the bond between the two different concrete layers is not as strong as it should be. Essentially, it is like two different pieces of a puzzle that don’t fit together perfectly.

Examples & Analogies

Imagine making a sandwich with two slices of bread. If you add your filling (like peanut butter or jelly) on one slice, and then leave it for too long before putting the other slice on top, the bread dries out. When you finally try to complete the sandwich, the two slices won't stick together well, making it unstable—similar to how cold joints affect concrete.

Weak Interface Consequences

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Weak interface if delay exceeds initial setting time.

Detailed Explanation

If too much time passes after the initial setting time of the first batch of concrete before the second batch is poured, the surface of the first batch may harden completely. This results in a weak interface where the two batches meet. This weak bond can lead to structural issues, such as cracks or even failure, under stress.

Examples & Analogies

Think of this like trying to glue two pieces of wood together. If one piece has already dried and set, when you apply glue—especially if you take a long time to do this—the glue won’t hold the pieces together effectively. The connection will be weak, much like how cold joints create weak areas in concrete.

Preventive Measures

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Use retarding admixtures.

• Reduce delay between mixing and placing.

• Re-tempering (adding water) is discouraged but can be done cautiously under strict quality control.

Detailed Explanation

To prevent cold joints from forming, certain measures can be implemented. One common method is to use retarding admixtures, which slow down the setting time of concrete, allowing more time for subsequent layers to be added without the risk of creating a cold joint. It's also critical to minimize the delay between mixing and placing the concrete to ensure layers bond properly. While re-tempering—adding a small amount of water to a concrete mix that is beginning to set—might seem like a solution, it is generally discouraged unless strict quality control measures are followed since it can compromise the strength of the concrete.

Examples & Analogies

This is similar to making a cake. If you allow the batter to sit too long before baking, it may not rise well or become fluffy. By using ingredients that delay setting, like certain baking powders, you can ensure the batter remains workable until you're ready to bake. However, adding too much water to an already mixed batter can ruin the cake, similar to how re-tempering can weaken concrete.

Key Concepts

-

Cold Joints: Result from delays in concrete placement and lead to weak interfaces.

-

Retarding Admixtures: Used to extend the setting time of concrete to prevent cold joints.

-

Initial Setting Time: The crucial time frame that must be managed to avoid cold joints.

Examples & Applications

In a construction project, workers delay pouring the second batch of concrete. The previously poured concrete sets, leading to a cold joint and weakening the structure.

Using a retarding admixture can extend the placement time for concrete, thus reducing the risk of a cold joint if implemented successfully.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

If you pour too late, a cold joint you'll make, a weak bond is the risk, so don't hesitate!

Stories

Imagine a baker who forgot to align his fresh batter with the already baked cake, resulting in a crumbly, weak layer. That's just like a cold joint!

Memory Tools

COLD: 'Cement Overlap Delays' to remember cold joint formation.

Acronyms

COLD

'Cautious On Layering Delays' to remind of the timing needed to avoid cold joints.

Flash Cards

Glossary

- Cold Joint

A cold joint occurs when new concrete is placed against hardened concrete, leading to a weak interface.

- Retarding Admixtures

Substances added to concrete to slow down the setting time, helping to reduce the risk of cold joints.

- Initial Setting Time

The time when concrete begins to lose its plasticity and hardens.

Reference links

Supplementary resources to enhance your learning experience.