Experimental Data Overview

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Mass Conservation in Fluid Flow

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today we will start with the principle of mass conservation in fluid flow. Can anyone tell me what it means when we say mass is conserved in a flow?

I think it means that the amount of fluid doesn't change as it moves through different parts of the system?

Exactly! We express this with the equation Q = AV, where Q is flow rate, A is the cross-sectional area, and V is velocity. This means that at different points in a pipe, the flow rate should remain constant.

But what if the diameter of the pipe changes?

Great question! If the diameter changes, then the velocities at different points will adjust to keep Q constant. Remember that flow rate is a product of area and velocity!

So, larger diameter means slower speed?

Yes, correct! It’s essential to visualize this: as fluid moves from a wider section to a narrower section, velocity increases. This concept will help us in designing piping systems effectively.

What about when flow is incompressible? Does the principle change?

Good observation! When flow is incompressible, the density remains constant, simplifying our calculations. We'll encounter this in our next discussion about momentum.

To recap, mass conservation ensures consistent flow rates throughout a system. Always keep in mind the relationship between area and velocity. Are there any questions before we proceed?

Momentum Equations in Fluid Dynamics

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let's talk about the application of linear momentum equations. Can anyone explain what linear momentum refers to in fluid dynamics?

I think it's how much motion a fluid has, right? Like how it moves in pipes or something?

Exactly! The momentum of a fluid is the product of its mass and velocity. We talk about the change in momentum in a fluid control volume.

So how do we calculate this change?

We use the equation that connects pressure force and momentum flux, considering how shear forces might be negligible in many cases. This allows us to simplify our calculations.

What does it mean ‘neglecting shear stress’? Isn’t all the fluid moving?

Good point! While fluid indeed moves, in many systems, the pressure forces are much larger than the shear stress effects, letting us focus on pressure differences alone.

Can we visualize this? I find it easier when I can see a diagram.

Visual aids are crucial! Sketching flow diagrams showing pressure points and velocities helps solidify our understanding of momentum changes.

To sum up, the momentum equation helps us analyze fluid forces in control volumes. Make sure to remember the conditions under which we can neglect shear stress. Any further questions on momentum before we move to Bernoulli?

Bernoulli’s Equation and Energy Losses

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let's turn to Bernoulli’s equation. Who remembers what this equation represents?

It’s about the energy in a fluid system, isn’t it? Like pressure, velocity, and height?

Exactly! Bernoulli’s equation relates these energies through a horizontal flow assumption. What do you suppose happens when there are losses in energy?

Does that mean the pressure or flow changes?

Correct! Energy losses can be due to friction and system changes, and that’s where we modify Bernoulli’s equation to include head losses. Who remembers the terms we use for energy loss?

Major and minor losses?

Yes! Major losses happen due to friction over long distances while minor losses occur from valves, fittings, and other components.

How do these minor losses affect system design?

Great question! Understanding these losses helps engineers choose the right components for efficient systems. Fluid dynamics is about optimizing designs for minimal energy loss.

To conclude, Bernoulli’s equation is a powerful tool in understanding energy dynamics in fluid systems. Make sure you grasp how energy losses influence pipe flow and design. Any last inquiries before we proceed?

Analyzing Valve Types and Energy Loss

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, let's examine how the type of valve influences fluid energy losses. Can anyone name a couple of valves we might encounter in piping systems?

Gate valves and globe valves!

Correct! Each type affects flow differently. Gate valves can create more energy loss than globe valves when partially opened. Can anyone explain why?

Is it because of how flow is distributed? Like turbulence?

Spot on! Turbulent flow leads to increased energy dissipation. As the valve opens or closes, it alters the flow regime, causing varying losses. This is critical for system design.

So how do we calculate these losses?

We can use empirical data, looking at loss coefficients for each valve type while considering flow rates and velocities. Reviewing tables of loss coefficients can help engineers make informed decisions.

Are these losses significant in larger systems?

Indeed! In larger systems, every bit of efficiency counts. Multiplying energy losses can lead to significant inefficiencies over time.

To summarize, understanding valve types shapes how we approach system efficiency while minimizing energy losses. Let’s ensure we grasp this principle before we tackle practical applications!

Velocity Distributions in Laminar vs. Turbulent Flow

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Finally, let’s discuss how flow type influences velocity distributions. Who can explain the difference between laminar and turbulent flows?

Laminar flow is smooth and orderly, while turbulent flow is chaotic and mixed.

Exactly! In laminar flow, fluid travels in parallel layers, affecting how each layer moves. What do you think happens in turbulent flow?

Different parts of the fluid can move at different speeds?

Yes, in turbulent flow, there’s a lot of mixing, leading to increased friction and energy losses. How do we account for these differences in design?

I assume we need to consider flow rates and adjust pipe sizing?

Absolutely! Engineers must evaluate the flow type and adjust designs accordingly, especially when enlarging or contracting pipes.

What about controlling turbulence?

Good point! Controlled elements such as straighteners can help manage turbulence in certain designs. Always aim for a balance between efficiency and control.

To wrap up, understanding flow types aids in optimizing design choices in pipe systems. This knowledge significantly impacts system performance. Ready for practical applications?

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

In this section, key fluid dynamics concepts such as mass conservation, linear momentum, and Bernoulli’s equations are explored. The influence of valve types, including gate valves and globe valves, on flow and energy losses in pipe systems are highlighted, connecting theory with practical applications and scenarios in fluid flow management.

Detailed

Detailed Summary

This section delves into understanding fluid flow in pipe systems through the application of fundamental principles like mass conservation, linear momentum equations, and Bernoulli’s equations. It emphasizes the importance of visualizing flow patterns, such as streamlines and vortex formations, and discusses various types of valves, including gate and globe valves. The section explains how operating these valves affects flow regulation and energy dissipation.

Key topics include:

1. Mass Conservation: Understanding how the flow rate (Q = AV) must remain constant through pipe systems where density is consistent.

2. Momentum Equations: Application of linear momentum equations to calculate forces in fluid flow and analyze shear stress neglecting minimal effects in certain conditions.

3. Bernoulli's Principle: Use of Bernoulli’s equations to relate pressure, velocity, and height within the flow, incorporating terms for energy losses due to friction in the system.

4. Impact of Valves: Comparing energy losses in gate and globe valves, systematically relating valve operation to energy efficiency in fluid control.

5. Velocity Distributions: Differentiating between laminar and turbulent flow and how they affect velocity distribution within pipes.

The overall significance is the integration of theoretical principles into practical fluid flow scenarios for enhanced comprehension and design of piping systems.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Valve Types and Flow Regulation

Chapter 1 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

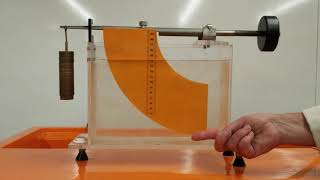

If you look it that most of the times also we have a valve to control the flow okay which is a gate valve okay, it is a gate type of systems. If you rotate it this valve closes the waters okay. And it can have a total open or half closed and all these conditions to regulate the flow to regulate the flow we have a these systems. Now if you look it if I am to draw the streamlines, how it happens it.

Detailed Explanation

Valves are important components in fluid systems as they control the flow of liquids. A gate valve is a type of valve that allows you to greatly adjust the flow by either fully opening or partially closing it. When the valve is adjusted, it regulates the amount of water flowing through the system. If we visualize the flow of water using streamlines (which are lines that represent the path of water flow), we can comprehend how water behavior changes based on the valve's position.

Examples & Analogies

Think of a garden hose with a nozzle. When you twist the nozzle, you can fully open, partially close, or completely shut off the water flow. Similarly, a gate valve can be adjusted to let more or less water pass through a pipeline, impacting how water moves through the system.

Flow Distribution and Vortex Formation

Chapter 2 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

So streamlines will come like this okay. There could be the vortex formations. And if you try to understand it, that I have not this open or the totally close, if the half open your flow distributions you can understand it how the streamlines patterns will come, how the vortex formations will have.

Detailed Explanation

When the valve is partially open, not only does the shape of the streamlines change, but vortex formations can also occur. Vortices are swirling motions that happen in the fluid as it flows around obstacles (like the partially closed valve). This alteration in flow can lead to different energy losses compared to when the valve is fully open or completely shut.

Examples & Analogies

Imagine swirling a spoon in a cup of coffee. If you move the spoon slowly, you create small eddies or swirls in the liquid. If the spoon is moved fast or blocked in some way, the flow pattern changes, leading to bigger swirling shapes. Similarly, how the valve is positioned affects the flow patterns in a pipe.

Types of Control Valves

Chapter 3 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Now if you look it similar way we have a the globe valve which is more control valve systems. The flow comes here, then rotate it and this valve it goes off and flow goes like this. So we can look it now in terms of vortex formations here, the vortex formations here, and once flow goes it also could have the vortex formations also here.

Detailed Explanation

Globe valves are another kind of control valve that help manage the flow of a fluid better than a gate valve. Unlike gate valves, globe valves provide finer control over the rate of flow. When the flow goes through a globe valve, it can also generate vortices, but because of its design, it handles the flow changes more effectively.

Examples & Analogies

Consider a faucet in your bathroom. When you turn the faucet knob, the water flow can be adjusted from a trickle to a strong stream. This is similar to how a globe valve works, offering precise control over water discharge, unlike a gate valve, which is more like an on/off switch.

Energy Loss Calculations

Chapter 4 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

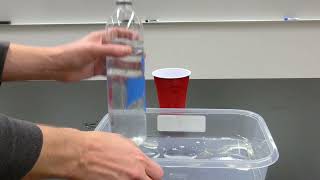

Let us come for derivations of energy losses and the pressure and velocity distributions of having a systems where two pipes we are enlarging it from the smaller diameter to bigger diameters.

Detailed Explanation

When changing the diameter of a pipe (enlarging from a smaller to a larger diameter), we need to calculate energy losses that occur due to friction and flow separation. These calculations are vital to understanding how fluid behaves in different pipe sizes and ensuring the system operates efficiently.

Examples & Analogies

Think of how difficult it is to suck juice through a thick straw versus a thin one. The thicker straw allows for a faster flow of juice, but it may also lead to more spills (energy losses) if you try to suck too hard. Understanding these fluid dynamics helps engineers design efficient piping systems.

Flow Types and Velocity Distributions

Chapter 5 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

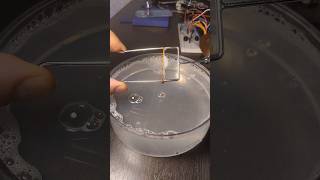

The velocity distribution it depends upon the type of the flow. If I have a laminar flow, the velocity distribution is different. If I have a turbulent flow velocity distributions is different.

Detailed Explanation

The flow of fluid can be classified as either laminar (smooth and orderly) or turbulent (chaotic and irregular). The way fluid velocity is distributed across the pipe's diameter changes significantly based on which type of flow it is. This distinction affects how engineers calculate pressure loss and design piping systems.

Examples & Analogies

Imagine stirring honey in a glass. If you stir gently, the honey moves smoothly in layers (laminar flow). If you start stirring rapidly, it splashes everywhere and mixes chaotically (turbulent flow). This analogy illustrates how the flow of a fluid can operate either smoothly or chaotically.

Key Concepts

-

Mass Conservation: The principle where a closed system maintains a constant flow rate due to the conservation of mass.

-

Momentum Equations: Formulas used to calculate changes in momentum within fluid systems, essential for analyzing forces.

-

Bernoulli’s Equation: An energy conservation equation connecting pressure, velocity, and height in flow.

-

Valve Efficiency: Different types of valves produce varying energy losses based on their design and operating conditions.

-

Flow Regimes: Differentiating between laminar and turbulent flow types impacts energy efficiency and flow characteristics.

Examples & Applications

In a pipe system with varying diameter, the flow rate remains constant; if the diameter decreases, the velocity increases according to the equation Q = AV.

A gate valve introduces more energy loss compared to a globe valve when partially opened because of increased turbulence in the flow.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

In a pipe that flows smooth and fine, mass stays the same, no loss, just design.

Stories

Imagine a river. As it widens, the speed slows. In a pipe, if we open a gate, the energy takes a drastic fate, swirling chaos replaces calm.

Memory Tools

Remember the flow types: Laminar is Like Layers, Turbulent is Topsy-Turvy.

Acronyms

M.E.B.V.

Mass conservation

Energy loss

Bernoulli

Valve impact

for remembering key concepts discussed.

Flash Cards

Glossary

- Mass Conservation

The principle stating that mass cannot be created or destroyed in a closed system, ensuring a constant flow rate in fluid dynamics.

- Momentum

The quantity of motion an object has, calculated by the product of its mass and velocity; in fluids, this refers to the motion of the fluid elements.

- Bernoulli’s Equation

An equation relating the pressure, velocity, and height in a flowing fluid, emphasizing energy conservation within a fluid system.

- Gate Valve

A type of valve that uses a gate to stop or allow the flow of fluid, often resulting in larger energy losses due to more turbulence.

- Globe Valve

A control valve that regulates flow and is generally more efficient than a gate valve for controlling flow due to its structured design.

- Turbulent Flow

A type of fluid flow characterized by chaotic changes in pressure and flow velocity, leading to energy loss.

- Laminar Flow

A flow regime where the fluid moves in smooth, parallel layers, resulting in lower energy losses.

Reference links

Supplementary resources to enhance your learning experience.