Reynolds Numbers and Flow Conditions

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Understanding Reynolds Numbers

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we'll discuss Reynolds numbers, which help us determine if a flow is laminar or turbulent. Can anyone tell me the significance of these two flow types?

I think laminar flow is smooth and streamlined, while turbulent flow is chaotic.

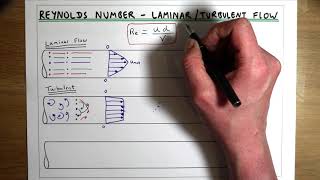

Exactly! Laminar flow occurs when the Reynolds number is below 2000, ensuring smooth streamlines. What about turbulent flow?

Turbulent flow happens when the Reynolds number exceeds 4000, right?

That's correct! Remember, for flows around 2000 to 4000, we have transitional flow. This is crucial in practical applications like pipe design.

Let's recap: Re < 2000 is laminar, Re > 4000 is turbulent, and 2000 < Re < 4000 is transitional.

Effects of Valves on Flow

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let's discuss valves and how they influence fluid flow. For instance, what happens when we partially open a gate valve?

I think it creates a lot of turbulence because it disrupts the flow.

That's right! A partially opened valve allows vortex formations and increases energy loss compared to fully opened conditions.

How does a globe valve compare to a gate valve?

Great question! A globe valve provides better flow control, but results in greater energy losses due to its restrictive shape. So, while it controls flow, be aware of the increased energy expenditure.

Let's summarize: gate valves may offer less resistance when fully open, but globe valves offer better control at significant energy costs.

Impact of Flow Velocity on Energy Losses

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Understanding velocity distribution in different flow conditions is crucial. Can someone explain how it changes in laminar versus turbulent flows?

In laminar flow, velocity is highest at the center of the pipe and decreases toward the edges, while in turbulent flow, it's more uniform.

So if we want to reduce energy loss, we should aim for laminar flow?

Not always! In many systems, we require turbulent flow for optimal mixing or heat exchange, but we must manage the associated energy losses carefully.

Let's recap key points: laminar flow has a distinct velocity profile, while turbulent flow exhibits broad distribution, leading to varying energy losses.

Applying Bernoulli’s Equation

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

As we apply Bernoulli’s equation, we must account for energy losses we encounter in a flow system. Who can remind us what Bernoulli’s equation states?

It relates the pressure, velocity, and height of fluid in a streamline.

Correct! We modify Bernoulli’s equation to include head losses. Thus, energy decreases along the stream due to friction and turbulence.

How do we compute these losses, though?

Good point! We quantify both major losses due to friction and minor losses related to fittings or valves, enabling precise energy forecasting in design.

To recap: energy losses are integral to applying Bernoulli effectively, helping us more accurately design fluid systems.

Practical Applications and Examples

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Finally, let's talk about real-world applications. How do the principles we've learned affect pipe design in engineering?

To ensure efficient flow rates and minimize energy loss in systems, right?

Can you give a specific example?

To summarize this section: understanding Reynolds numbers, flow conditions, and energy loss is pivotal in engineering fields, especially fluid dynamics.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

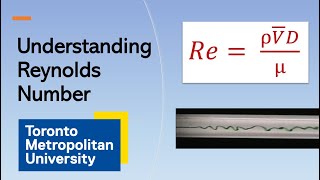

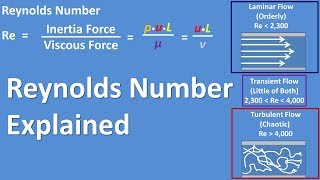

The discussion revolves around Reynolds numbers and their significance in determining flow conditions, including laminar and turbulent flows. It also covers the interaction of various valve types and the implications of energy losses during fluid flow, particularly in relation to mass and momentum conservation equations.

Detailed

Detailed Summary

In this section, we examine the importance of Reynolds numbers in understanding flow conditions. A Reynolds number allows us to distinguish between laminar flow (Re < 2000) and turbulent flow (Re > 4000). The flow characteristics can be significantly influenced by devices such as gate valves and globe valves. The dynamics of flow through these devices lead to vortex formations and energy losses, which are critical in determining the efficiency of fluid transport systems.

The principles of mass conservation and linear momentum equations are also applied to analyze energy losses during flow transitions, especially when the diameter of a pipe changes from smaller to larger. The velocity distributions differ in laminar and turbulent flow scenarios, necessitating the application of Bernoulli’s equation, which helps quantify energy losses associated with minor and major losses in the system.

Understanding these concepts is vital for engineers who design piping systems and manage fluid transportation.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Understanding Flow Control with Valves

Chapter 1 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

If you look it that most of the times also we have a valve to control the flow okay which is a gate valve okay, it is a gate type of systems. If you rotate it this valve closes the waters okay. And it can have a total open or half closed and all these conditions to regulate the flow to regulate the flow we have a these systems. Now if you look it if I am to draw the streamlines, how it happens it. So streamlines will come like this okay. There could be the vortex formations. And if you try to understand it, that I have not this open or the totally close, if the half open your flow distributions you can understand it how the streamlines patterns will come, how the vortex formations will have.

Detailed Explanation

In this chunk, we are learning about how valves, specifically gate valves, control fluid flow within a system. When a gate valve is fully open, water can flow freely. When it is partially closed (half closed), the fluid flow becomes restricted, which can create changes in the fluid dynamics, such as different patterns of streamlines and potential vortex formations. By drawing or visualizing the streamlines, one can better understand how varying the openness of the valve alters the flow conditions.

Examples & Analogies

Think of the gate valve like a water hose. When you cover part of the hose with your thumb, the water sprays out with more force, but its overall flow is reduced. When you remove your thumb, the hose allows water to flow freely. This concept is similar to how a gate valve operates at different levels, affecting how water streams through it.

Energy Loss Due to Valve Use

Chapter 2 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

If you look at these conditions you can easily interpret it we will have a more energy losses for this case as compared to this ones. But we need sometimes this type of valve to control the flow systems.

Detailed Explanation

Using different types of valves, like globe and gate valves, affects energy losses in a fluid system. Globe valves typically provide more control over flow but cause greater energy losses due to their design, which creates turbulence as fluid passes through them. Despite this, controlling flow is sometimes necessary, which means we must accept certain energy losses in exchange for better regulation of fluid motion.

Examples & Analogies

Imagine driving a car on a windy road. If you go too fast, you’ll have to frequently brake (implying energy loss), but if you slow down, you can navigate the curves better (implying better control). The same principle applies here: some valve setups may lead to greater energy loss, but ensure better management of flow conditions.

Applying Mass Conservation and Momentum Equations

Chapter 3 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Let us come for derivations of energy losses and the pressure and velocity distributions of having a systems where two pipes we are enlarging it from the smaller diameter to bigger diameters. If you have that conditions and you can draw the velocity distributions. The velocity distribution it depends upon the type of the flow. If I have a laminar flow, the velocity distribution is different. If I have a turbulent flow velocity distributions is different.

Detailed Explanation

This part discusses how energy losses and the distribution of velocity can change when fluid flows through pipes of varying diameters. We differentiate between laminar and turbulent flow, where laminar flow is smooth and orderly, resulting in a different velocity profile compared to turbulent flow, which is chaotic. This distinction is crucial because the flow type influences energy losses and system design.

Examples & Analogies

Think of a river. In some areas, the water flows slowly and smoothly (laminar flow), while in other areas, it rushes wildly with waves and currents (turbulent flow). The smoother the flow, the less energy the water loses to friction with the riverbed, just as laminar flow experiences less energy loss compared to turbulent flow.

Using Bernoulli's Equation for Energy Loss Quantification

Chapter 4 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Now I will applying Bernoulli’s equations along the straight line, okay I am just applying the Bernoulli’s equation along the straight line. When you apply the Bernoulli’s equations, this line is horizontal. This streamline is horizontal, so you do not have a z components. You have pressure head component and the velocity head component.

Detailed Explanation

In this segment, we apply Bernoulli’s equation, which helps quantify the energy in a flowing fluid. Here, we focus on a horizontal streamline scenario, meaning we only consider pressure head and velocity head because there’s no change in height (z-component) affecting the energy. The key is to balance the energy terms to determine losses as the fluid moves through different sections.

Examples & Analogies

Imagine a roller coaster: as the coaster moves down (pressure and velocity), it speeds up. Bernoulli's principle works similarly by calculating what's happening to energy at different points along a track with no height changes. The 'slope' of energy talking about energy loss comes from how friction affects speed similar to how air friction slows down the coaster.

Friction Factors and Flow Calculations

Chapter 5 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Now if you look at the tabular values what we have and here I am talking about the head loss is equal to ... The K value. How does they value it. First is gate conditions which is 0.18 can varies up to 0.10 as the diameters increases. Similar way, if you look it that, gate valve is 0.18, 7.80.

Detailed Explanation

Here, we quantify energy losses using a factor known as K, which takes into account different conditions like valve type and pipe diameter. These K values allow engineers to calculate energy losses in the system accurately. Understanding these values helps in designing efficient fluid systems.

Examples & Analogies

Think about gearing up for a bike race: the type of gear you use (low or high) impacts how hard it is to pedal (energy loss). Similarly, knowing the K value is like knowing the gear setting; it tells you the energy loss you’d face, helping you choose the right setup for your design.

Key Concepts

-

Reynolds Number: Predicts flow type based on fluid behavior.

-

Flow Conditions: Differences between laminar and turbulent flow.

-

Energy Loss: Important for efficiency in fluid systems.

-

Bernoulli’s Equation: Fundamental equation for fluid dynamics.

Examples & Applications

When designing a water distribution system, knowing the Reynolds number helps ensure the flow remains turbulent to promote mixing.

In HVAC systems, control valves are chosen based on their energy loss characteristics to optimize performance.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Reynolds number tells you flow's fate, below two grand's a smooth state, rise above four, chaos awaits!

Stories

Imagine a river where fish swim calmly, that's laminar flow. Now picture a storm with turbulent waters crashing against rocks, that’s turbulent flow!

Memory Tools

Remember the acronym 'LETS' for Laminar Equals Tranquil Stream.

Acronyms

Use 'VEL' to recall Velocity, Energy, Loss from fluid dynamics principles.

Flash Cards

Glossary

- Reynolds Number

A dimensionless number used to predict flow patterns in different fluid flow situations, distinguishing laminar from turbulent flow.

- Laminar Flow

A smooth and orderly flow regime characterized by parallel streamlines and little to no turbulence.

- Turbulent Flow

A chaotic flow regime where irregular fluctuations and vortices occur, usually indicated by a Reynolds number greater than 4000.

- Bernoulli’s Equation

A principle that relates the pressure, velocity, and height of fluid in a streamline, allowing for the calculation of energy changes in flowing fluids.

- Energy Loss

The decrease in mechanical energy (due to friction, turbulence, etc.) as fluid flows through pipes and fittings.

- Gate Valve

A valve that opens or closes to control fluid flow, providing minimal restriction when fully open.

- Globe Valve

A type of valve that regulates flow with better control but incurs greater energy losses due to its design.

Reference links

Supplementary resources to enhance your learning experience.