Flow Control Valves

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Flow Control Valves

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're discussing flow control valves, which are crucial in regulating fluid flow. Can anyone tell me why controlling flow is important?

It's important for managing pressure and ensuring efficient system operation.

Exactly! We have different types of valves like gate and globe valves. The gate valve is more straightforward while the globe valve allows for better control. Can anyone think of a situation where each type would be used?

I think a globe valve would be great for a variable flow application.

And a gate valve would be better for just turning the flow on or off.

Great insights! Remember, we classify them based on the discharge conditions they handle.

Energy Losses in Valves

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's delve into energy losses in these valves. When flow is partially obstructed, how do you think that impacts energy?

I think it would increase energy loss because of turbulence.

Correct! When a valve is half open, it causes vortex formations and turbulence, increasing energy loss compared to when fully open. Can anyone elaborate on how we can calculate these losses?

We use Bernoulli’s equation, right? It helps us understand energy transformations in the system.

Yes! We will apply Bernoulli’s principles along with mass conservation equations to analyze these scenarios.

For memory, remember the acronym K for understanding energy loss coefficients due to valves and fittings.

Flow Rate Calculations

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let’s look at how flow rates change with different pipe diameters. What happens during a step-up from a smaller to a larger diameter?

The flow speed could change, and we could have different velocity distributions depending on the flow type, right?

Absolutely! For instance, in laminar flow versus turbulent flow, the velocity profile differs significantly. How do we model that mathematically?

Using the continuity equation: Q = A * V, where A is the cross-sectional area and V is the velocity.

Exactly! And when we apply Bernoulli’s principle, we account for energy loss in our computations. Don’t forget to sketch your energy gradient and hydraulic gradient lines!

Practical Applications

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Lastly, let’s connect our discussions to real-world applications. How would a civil engineer use this knowledge of flow control valves?

They would need to select the right valve for designing efficient water supply systems.

That’s correct, especially in minimizing energy losses. Can anyone recall a specific example where pipe design impacted flow management?

Maybe in firefighting systems, where proper valve selection is crucial for pressure maintenance?

Exactly! Selecting the appropriate valve can greatly influence operational efficiency. Remember these concepts as they are foundational in fluid dynamics.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section covers the functioning of various types of flow control valves, emphasizing their design, energy losses, and the application of mass conservation and momentum equations in fluid dynamics. Understanding the differences between gate and globe valves is crucial for optimal system design.

Detailed

Flow Control Valves

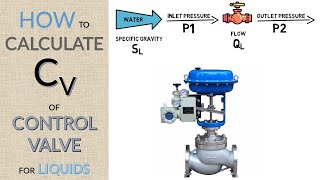

Flow control valves play a vital role in managing fluid flow in various engineering systems. This section begins by explaining foundational concepts related to fluid dynamics and the significance of valve selection based on desired discharge conditions. Valves such as gate valves and globe valves are examined in detail, highlighting their operational mechanisms—gate valves control flow through rotation to close or open paths, while globe valves provide more precise regulation of flow.

The interaction between these valves and fluid behavior is explored through concepts like vortex formation and energy dissipation, especially under different flow conditions (e.g., half-open vs closed states). The discussion proceeds to energy loss derivations, illustrating the application of mass conservation equations and Bernoulli’s principles to analyze pressure and velocity distributions across different pipe geometries, including scenarios of gradual contractions or enlargements.

By understanding these mechanisms, engineers can better design fluid systems that minimize energy losses and efficiently manage flow rates. The section also emphasizes the importance of energy gradient and hydraulic gradient lines as tools for analyzing flow, providing insights into the efficiency of various pipeline configurations.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Introduction to Flow Control Valves

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

If you look it that most of the times also we have a valve to control the flow okay which is a gate valve okay, it is a gate type of systems. If you rotate it this valve closes the waters okay. And it can have a total open or half closed and all these conditions to regulate the flow to regulate the flow we have a these systems.

Detailed Explanation

Flow control valves are essential components in fluid systems. A popular type of flow control valve is the gate valve. This valve works by rotating to either open or close the flow of fluid. When fully open, the valve allows maximum flow, while in a half-open position, it allows for reduced flow. Understanding these operational states is crucial for regulating fluid dynamics in various systems.

Examples & Analogies

Think of a gate valve like a water faucet in your home. When the faucet is fully opened, you get a strong stream of water. If you partially close it, you lessen the water's flow, similar to how a gate valve operates. This type of control helps manage the flow rate of water through pipes in a structured way.

Flow Patterns and Vortex Formations

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Now if you look it if I am to draw the streamlines, how it happens it. So streamlines will come like this okay. There could be the vortex formations. And if you try to understand it, that I have not this open or the totally close, if the half open your flow distributions you can understand it how the streamlines patterns will come, how the vortex formations will have.

Detailed Explanation

When examining flow through valves such as the gate valve, streamlines illustrate how the fluid moves. Streamlines represent the paths followed by particles in the flow. Depending on the valve's position (fully open, half open, or closed), the pattern of these streamlines changes. For instance, a half-open valve may lead to more complex flow patterns, including vortex formations, which can disrupt smooth flow and increase energy dissipation.

Examples & Analogies

Imagine water flowing through a garden hose. When you cover part of the opening with your finger, the water flows faster through the narrow opening, creating turbulent patterns and eddies. This turbulent behavior is similar to the vortex formations discussed when analyzing streamlines in partially open valves.

Comparison of Valve Types

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Now if you look it similar way we have a the globe valve which is more control valve systems. The flow comes here, then rotate it and this valve it goes off and flow goes like this. So we can look it now in terms of vortex formations here.

Detailed Explanation

The globe valve is another type of flow control valve that provides more precise control than a gate valve. The design allows for throttling or partial flow regulation more effectively. When analyzing the globe valve operation, similar conditions of flow distribution and vortex formation apply, but the globe valve typically leads to higher energy losses compared to the gate valve due to its design and function.

Examples & Analogies

Think of a globe valve like a dimmer switch for a light. A light switch simply turns the light on or off, while a dimmer allows you to adjust the brightness, giving you more control over how bright the room is. Similarly, a globe valve allows for finer control over fluid flow, unlike a gate valve, which is better suited for full on or off control.

Energy Losses and Flow Conditions

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

If you look at these conditions you can easily interpret it we will have a more energy losses for this case as compared to this ones. But we need sometimes this type of valve to control the flow systems.

Detailed Explanation

Using different types of valves impacts the energy efficiency of the fluid system. Globe valves may lead to higher energy losses when compared to gate valves due to their design. Despite the increased losses, the ability to finely adjust the flow makes globe valves necessary in specific applications requiring precise control.

Examples & Analogies

Consider driving a car; moving along a straight road at full throttle uses less fuel compared to constantly stopping and starting at intersections. In a hydraulic system, a gate valve allows for quick flow with minimal energy loss, but for applications like adjusting water levels or pressure, the finer control from a globe valve, despite more energy loss, is crucial for smooth operation.

Key Concepts

-

Mass Conservation: The principle that mass must remain constant in a closed system.

-

Momentum Equations: Equations used to analyze forces and motion in fluid systems.

-

Energy Dissipation: Loss of energy in the form of heat, turbulence, or friction during flow.

Examples & Applications

When a gate valve is fully open, there is minimal resistance to flow; however, if it is partially closed, higher turbulence and energy losses occur.

In a piping system with various diameters, as fluid flows from a smaller to a larger pipe, it may decelerate, affecting pressure and velocity profiles.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Valve control we can't dismiss, flows we guide with twist and hiss.

Stories

Imagine a river with branches; some are wide and calm (like a globe valve), while others are narrow and swift (like a gate valve), each controlling the flow differently.

Memory Tools

Remember K for key concepts: K for losses, K for control, K for flow in a valve's role.

Acronyms

VALVE

Viscosity

Area

Loss

Velocity

Energy - key elements in flow control.

Flash Cards

Glossary

- Flow Control Valve

A device used to manage the flow rate of fluids in a system.

- Gate Valve

A valve that opens by lifting a barrier out of the path of the fluid, used primarily for on/off control.

- Globe Valve

A valve that uses a spherical body to provide better control over fluid flow.

- Energy Loss

The loss of energy in a fluid system due to factors such as friction, turbulence, or obstructions.

- Bernoulli’s Equation

An equation that describes the conservation of energy principle for flowing fluids.

- Momentum Flux

The rate of flow of momentum across a surface.

- Hydraulic Gradient Line

A line representing the total head at various points in a pipe system, accounting for energy losses.

Reference links

Supplementary resources to enhance your learning experience.