Bituminous Cutbacks

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Definition and Importance of Bituminous Cutbacks

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we will learn about bituminous cutbacks. Can anyone tell me what they think a bituminous cutback is?

Is it something like a kind of asphalt?

Great start! A bituminous cutback is actually a mixture of bitumen and a volatile solvent that reduces viscosity, allowing it to be easily handled at ambient temperatures.

Why do we need to reduce viscosity?

Excellent question! Reducing viscosity is essential because it helps in the application of bitumen without needing high heat, which can be costly and hazardous.

So, after applying it, what happens to the solvent?

After application, the solvent evaporates, leaving a stable bituminous film. This film binds aggregates effectively for a strong road surface.

Can we remember the definition with a mnemonic?

Great idea! Let’s say: 'Bitumen and solvent mix; cutbacks are the fix.' This helps us recall the basics.

To sum up, bituminous cutbacks are crucial in modern road construction for effective application at lower temperatures.

Types of Bituminous Cutbacks

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let's discuss the types of bituminous cutbacks. Can anyone tell me what are the classifications based on curing time?

I think there are rapid, medium, and slow curing types?

"Correct! Let’s clarify those more:

Preparation and Characteristics of Bituminous Cutbacks

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s move on to the preparation of bituminous cutbacks. What are some key steps in creating these mixtures?

We must heat the bitumen and then mix it with the solvent, right?

Exactly! The process involves heating bitumen, mixing it with a solvent, and monitoring the temperature to avoid hazards. Why do you think careful monitoring is essential?

To prevent fires, I guess?

Absolutely! Fire risks are significant when dealing with volatile solvents. Now, what characteristics should we look for in a quality cutback?

Lower viscosity and good workability?

Yes! Lower initial viscosity makes cutbacks more workable at ambient temperatures. Also, we check for penetration and ductility of the residue post-application.

How do those factors impact its performance?

Good point! Penetration affects how well the cutback binds aggregates, while ductility indicates its flexibility, critical for road surfaces. Remember: Penetration for bonding, ductility for flexibility!

In summary, proper preparation and understanding of characteristics ensure effective application and performance of bituminous cutbacks.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section explores the nature of bituminous cutbacks, which are created by dissolving bitumen in volatile solvents to improve its workability at room temperature. The section classifies cutbacks based on curing time and discusses their preparation, characteristics, applications, and the testing methods used to assess their properties.

Detailed

Bituminous Cutbacks

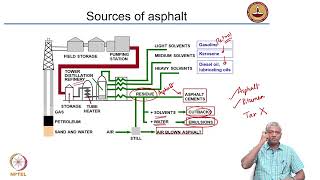

Bituminous cutbacks are produced by dissolving bitumen in a volatile solvent, such as naphtha or kerosene, to reduce viscosity and enhance fluidity at ambient temperatures. The solvent evaporates after application, leaving a bituminous film that serves as an effective binder in various road construction applications.

Types of Bituminous Cutbacks

Cutbacks are mainly classified according to their curing times:

1. Rapid Curing (RC): Utilizing highly volatile solvents, these cutbacks evaporate quickly and are suitable for surface treatments, like spray applications.

2. Medium Curing (MC): These use moderately volatile solvents for an intermediate evaporation rate, making them ideal for premixing with coarse aggregates.

3. Slow Curing (SC): Made with low volatility oils, these cutbacks evaporate slowly and are suitable for prime coats or stabilization.

Preparation of Bituminous Cutbacks

The preparation involves heating bitumen and mixing it with the desired solvent under controlled conditions, ensuring the process is monitored carefully to avoid fire hazards.

Characteristics of Bituminous Cutbacks

Cutbacks exhibit lower initial viscosity compared to pure bitumen, which improves their workability at lower temperatures. The setting time is dependent on the type of solvent used, and key quality indicators include the penetration and ductility of the residual bitumen after evaporation.

Applications and Tests

Bituminous cutbacks are used in tack and prime coats, cold patch work, and soil stabilization. Various tests, such as the distillation test and penetration test, are used to assess properties like consistency and safety.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Definition of Bituminous Cutbacks

Chapter 1 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Bituminous cutbacks are prepared by dissolving bitumen in a volatile solvent (e.g., naphtha, kerosene) to reduce viscosity and enhance fluidity at ambient temperature. After application, the solvent evaporates, leaving behind a bituminous film.

Detailed Explanation

Bituminous cutbacks are a particular type of material used in road construction. They are made by mixing bitumen, which is a thick black adhesive substance, with a solvent that easily evaporates, like naphtha or kerosene. This process lowers the viscosity of the bitumen, making it easier to apply at room temperature. When the cutback mixture is applied to a surface, the volatile solvent evaporates, which leaves a coating of bitumen on the surface, creating a strong bond as it dries.

Examples & Analogies

Imagine how syrup is thick and hard to pour at room temperature. If you mix it with hot water (the solvent), it becomes easier to pour. After the mixture cools down, the water evaporates, and you're left with thick syrup. In the same way, we mix bitumen with a solvent to make it easier to apply, and once the solvent evaporates, we get a solid bituminous film.

Types of Bituminous Cutbacks

Chapter 2 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Classified based on curing time, which depends on the type of solvent used: 1. Rapid Curing (RC): Uses highly volatile solvents like gasoline. Quick evaporation. Used for surface treatments like spray application. 2. Medium Curing (MC): Uses moderately volatile solvents like kerosene. Intermediate rate of evaporation. Used for premix with coarse aggregates. 3. Slow Curing (SC): Uses low volatility oils. Very slow evaporation. Suitable for prime coats or stabilization.

Detailed Explanation

Bituminous cutbacks are categorized based on how quickly they cure or harden after application, which is influenced by the type of solvent used in their formulation. There are different classes: 'Rapid Curing (RC)' uses highly volatile solvents that evaporate quickly, making it suitable for quick surface treatments. 'Medium Curing (MC)' employs moderately volatile solvents for a medium evaporation rate, and is great for mixing with aggregates. 'Slow Curing (SC)' uses low volatility solvents, allowing for a very slow curing process, perfect for applications that need more time for setting.

Examples & Analogies

Think of cooking pasta. If you turn up the heat (like using a rapidly evaporating solvent), the water boils quickly and the pasta cooks fast (like RC). If you simmer it gently (like MC), it cooks evenly, just not as quickly. If you keep it on very low heat (like SC), it takes even longer to cook, but the result can be very tender, just as slow-curing cutbacks are suited for different applications.

Preparation of Bituminous Cutbacks

Chapter 3 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Bitumen is heated and mixed with the desired solvent in a controlled environment. Careful monitoring of temperature is necessary to prevent fire hazards. The resulting liquid is cooled and stored in sealed containers.

Detailed Explanation

The preparation of bituminous cutbacks involves heating bitumen to ensure it mixes well with the solvent. This is done under controlled conditions to avoid any risks of fire, since both bitumen and the solvents can be flammable. Once mixed thoroughly, the liquid is allowed to cool before being stored in sealed containers to maintain its quality and prevent contamination.

Examples & Analogies

Preparing bituminous cutbacks is like making a salad dressing. You need to carefully combine oil (bitumen) with vinegar (solvent) at just the right temperature to get a smooth mix. If you mix too fast or too hot, you risk splattering (fire hazard), but once you have a good mixture, you cool it, seal it, and store it for later use.

Characteristics of Bituminous Cutbacks

Chapter 4 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Lower initial viscosity compared to pure bitumen. • Improved workability at lower temperatures. • Setting time determined by solvent type. • Penetration and ductility of the residue are key quality indicators.

Detailed Explanation

Bituminous cutbacks have distinct characteristics, including lower viscosity, which allows them to flow more easily compared to pure bitumen. This makes them easier to work with, especially in cooler conditions. The time it takes for them to set and harden depends on the type of solvent used. Additionally, once the cutback dries, the penetration and ductility of the remaining bitumen are critical indicators of its quality, affecting its performance in real-world applications.

Examples & Analogies

Imagine using a thick paint versus a thinner paint. Thinner paint (like bituminous cutbacks) flows and spreads easier, especially when it's a bit cool, whereas thick paint (pure bitumen) is harder to work with. The time it takes for your painted surface to dry can vary based on the type of thinner used in that paint, just like the curing time of cutbacks differs based on the solvent.

Tests on Bituminous Cutbacks

Chapter 5 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Distillation Test • Measures the percentage of volatile solvent. • Helps determine cutback classification (RC, MC, SC). 2. Penetration Test • Indicates consistency of residual bitumen. 3. Ductility Test • Measures the ability of residue to stretch without breaking. 4. Flash Point Test • Assesses safety and fire risk. 5. Viscosity Test • Important for handling and application.

Detailed Explanation

Several tests are essential for evaluating the quality of bituminous cutbacks. The Distillation Test examines how much solvent can evaporate and helps classify the cutback type. The Penetration Test assesses how thick or thin the remaining bitumen is after evaporation, while the Ductility Test measures how much the residue can stretch before breaking. The Flash Point Test evaluates safety by checking how easily the cutback can catch fire, and finally, the Viscosity Test is conducted to ensure it can be easily handled and applied.

Examples & Analogies

Think of these tests like checking a cake before serving it. The distillation test is like checking if all the ingredients are blended well, the penetration test checks if the cake is cooked through, the ductility test checks how well it can be cut without falling apart, the flash point test is like checking if the cake is safe to eat (not burnt), and the viscosity test is similar to seeing if the cake batter is the right thickness for baking.

Uses of Bituminous Cutbacks

Chapter 6 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Tack and Prime Coats • Premix for Cold Patch Work • Dust Palliatives in Rural Roads • Soil Stabilization • Fog Seal Applications

Detailed Explanation

Bituminous cutbacks have versatile applications in road construction and maintenance. They can serve as tack and prime coats, which help in bonding layers of materials. They are also used for cold patch work, allowing for repairs in colder conditions. Moreover, they help control dust on rural roads and stabilize soils in various projects. Finally, fog seal applications use cutbacks to protect and enhance existing surfaces.

Examples & Analogies

Imagine a chef using various sauces for different dishes. Just like that, bituminous cutbacks are used in multiple ways: as a sauce to bond layers, to fix damaged roads (like adding cheese to a pizza), to keep the dust down on rural paths (similar to using spices to enhance flavor), and to stabilize ground for construction (like using a special coating on delicate fruits).

Key Concepts

-

Bituminous cutback: A binder made from bitumen and a volatile solvent.

-

Curing types: Classification of cutbacks based on the rate of solvent evaporation.

-

Preparation process: Involves heating bitumen and mixing with a solvent.

-

Key characteristics: Lower viscosity and workability at lower temperatures.

Examples & Applications

Rapid curing cutbacks are commonly used in surface treatments during road construction, providing a quick-drying layer.

Slow curing cutbacks are suited for prime coating applications that require longer setting times to ensure adhesion.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Cutbacks blend bitumen with a solvent fun, they make road work easy; setting’s soon done!

Stories

Imagine a construction worker mixing a potion of bitumen and a magic liquid. As the sun shines, the liquid vanishes, leaving behind a strong road that can carry the heaviest trucks.

Memory Tools

R-M-S: Remember the order of cutbacks – Rapid, Medium, Slow!

Acronyms

C-B-S

Cutback

Binder

Solvent - the elements of a successful bituminous cutback!

Flash Cards

Glossary

- Bituminous Cutback

A mixture of bitumen and a volatile solvent that reduces viscosity and enhances fluidity at ambient temperatures.

- Rapid Curing (RC)

Cutbacks formed with highly volatile solvents for quick evaporation, suitable for surface treatments.

- Medium Curing (MC)

Cutbacks made with moderately volatile solvents, allowing for an intermediate evaporation rate.

- Slow Curing (SC)

Cutbacks utilizing low-volatility solvents with very slow evaporation, ideal for prime coats or stabilization.

- Penetration Test

A test used to assess the consistency of the residual bitumen after a cutback has cured.

- Ductility Test

A test measuring the ability of the residual bitumen to stretch without breaking.

- Volatile Solvent

A liquid that evaporates easily at normal temperatures and is used to dissolve bitumen in cutbacks.

Reference links

Supplementary resources to enhance your learning experience.