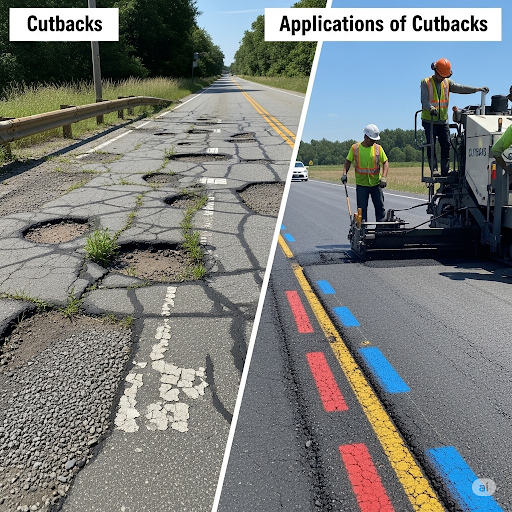

Uses of Bituminous Cutbacks

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Uses.

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're exploring the diverse uses of bituminous cutbacks in construction. Can anyone share what they think this material is used for?

I think they are used for preserving roads.

That's correct! Specifically, bituminous cutbacks are used for applications like tack and prime coats. Tack coats bond different layers in road construction. Remember, 'Tack = Bond' — a simple way to connect the concept!

What about other uses? Are there specific types of repair work they help with?

Absolutely! Cutbacks are crucial for cold patch work, especially in winter, when temperatures make traditional methods challenging. This is called 'Cold Patch = Quick Fix.'

Specific Applications.

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Beyond tack coats, do you know other areas where cutbacks excel?

Maybe something with dust control?

Exactly! Cutbacks are also employed as dust palliatives on rural roads, making travel safer by reducing dust clouds. Remember: 'Dust = Visibility.'

What about soil stabilization?

Good point! They stabilize soil by enhancing the properties of subgrades, crucial for foundational support. You can think of it as 'Stabilize = Firm Foundation.'

Environmental Relevance.

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

How do you think the use of bituminous cutbacks affects the environment?

They might be harmful due to solvents, but they help with maintenance.

Good observation! Although cutbacks can release volatile organic compounds, they are essential for effective road maintenance. Balance is key: 'Maintenance = Safety.'

Does that mean we need special handling?

Yes, proper handling and knowledge of risks are essential for safety. That's why we say 'Safety First!'

Conclusion and Recap.

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

To wrap up, can anyone summarize the key applications of bituminous cutbacks we've discussed?

They are used for tack coats, cold patch work, dust control, and soil stabilization!

Perfect! Remember, these applications are interconnected and crucial for road safety and maintenance. Keep those key phrases in mind as they will help solidify your understanding!

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section discusses the practical applications of bituminous cutbacks, explaining their importance in construction processes such as tack and prime coats, cold patch work, and soil stabilization. It emphasizes their versatility and utility in maintaining road conditions.

Detailed

Uses of Bituminous Cutbacks

Bituminous cutbacks, which involve the dissolution of bitumen in volatile solvents to enhance fluidity and ease of application, are utilized extensively in the construction industry. Their primary uses include:

- Tack and Prime Coats: Cutbacks are applied as tack coats to ensure firm bonds between different layers of road materials, enhancing overall structural integrity.

- Premix for Cold Patch Work: They are vital for creating premixes used in cold patching, facilitating maintenance repairs and ensuring road safety during colder months when traditional methods may be ineffective.

- Dust Palliatives in Rural Roads: Their ability to bind soil particles together makes them effective for dust control on unpaved roads, improving visibility and environmental conditions.

- Soil Stabilization: Cutbacks contribute to the stabilization of soil, especially in road construction, where the properties of the subgrade need enhancement.

- Fog Seal Applications: Lastly, fog seals using cutbacks can rejuvenate oxidized surfaces, extending the life of roadways while improving surface noticeably.

Thus, this section underscores the critical role that bituminous cutbacks play in varying aspects of construction, making them essential for effective road management and maintenance.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Tack and Prime Coats

Chapter 1 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Tack and Prime Coats

Detailed Explanation

Bituminous cutbacks are often used as tack and prime coats in road construction. A tack coat is a thin layer of bituminous material that is applied to the surface of a pavement to promote bonding between layers. This is essential when a new layer of asphalt is added atop an existing surface. Similarly, a prime coat is applied to unsealed surfaces, stabilizing the substrate and preparing it for subsequent layers.

Examples & Analogies

Think of tack and prime coats like a glue that helps stick new pieces of paper onto an old piece of cardboard. Without the glue, the new paper may not adhere well, leading to peeling or separation later on.

Premix for Cold Patch Work

Chapter 2 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Premix for Cold Patch Work

Detailed Explanation

Bituminous cutbacks serve as premixes for cold patch work, allowing for quick repairs of potholes and surface damage in asphalt roads without the need for heating. The cutback's fluid nature makes it easy to apply, and it adheres well to existing surfaces, filling in gaps and creating a durable repair.

Examples & Analogies

Imagine filling a hole in a wall with a soft putty that can be molded easily, just like how a cold patch works to fill potholes. This way, you don't have to heat the putty, making the repair process faster and more convenient.

Dust Palliatives in Rural Roads

Chapter 3 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Dust Palliatives in Rural Roads

Detailed Explanation

In rural areas, bituminous cutbacks are used as dust palliatives. They help in controlling dust on unpaved roads by binding the surface materials together, reducing airborne particles that can be harmful to health and visibility. This makes traveling safer and more pleasant on these roads.

Examples & Analogies

Think of how a damp sponge can help reduce dust when cleaning a surface. Bituminous cutbacks act like that damp sponge, keeping the road surface moist and preventing dust from kicking up as vehicles drive by.

Soil Stabilization

Chapter 4 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Soil Stabilization

Detailed Explanation

Bituminous cutbacks can also be used for soil stabilization, where they help in binding soil particles together to improve the load-bearing capacity and strength of the ground. This is particularly useful for constructing roads over weak or loose soils, ensuring that the roadbed is stable and capable of supporting traffic.

Examples & Analogies

Consider how glue holds together tiny pieces of a puzzle, enhancing its overall strength. Similarly, when bituminous cutbacks are mixed with soil, they act like glue, holding the soil particles together to create a solid foundation for roads.

Fog Seal Applications

Chapter 5 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Fog Seal Applications

Detailed Explanation

Fog sealing is another important use of bituminous cutbacks. This involves applying a thin layer of cutback to the surface of an existing pavement to rejuvenate the asphalt, sealing small cracks and preventing moisture intrusion. This application extends the life of the pavement and enhances its durability against weathering.

Examples & Analogies

Think of fog sealing as putting a protective coating on a wooden surface to prevent it from getting damaged by moisture. It rejuvenates and protects the pavement similarly by sealing in the asphalt and preventing decay.

Key Concepts

-

Tack and Prime Coats: These are essential for ensuring strong bonds between layers in construction.

-

Cold Patch Work: An effective method utilized during cold weather for road surface repair.

-

Dust Control: Helps maintain safety and visibility on unpaved roads by reducing dust emissions.

-

Soil Stabilization: Necessary for improving the load-bearing capacity of road bases.

Examples & Applications

In rainy climates, cutbacks may be preferred for sealing joints due to their improved fluidity.

Dust control strategies often involve applying cutbacks to gravel roads to limit loose materials.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Cutback for tack, patch, and dust, a road's best friend, that's a must!

Stories

Once in a town, the roads were dry, with dust clouds raising from trucks that fly. But a wise engineer, with cutbacks in hand, saved the day, making roads less bland.

Memory Tools

TDS - Tack, Dust, Soil stabilization - key uses of cutbacks.

Acronyms

TAC - Tack, Application, Control for effective road management.

Flash Cards

Glossary

- Bituminous Cutback

A mixture of bitumen dissolved in a volatile solvent to reduce viscosity and enhance fluidity.

- Tack Coat

A thin layer of a sticky substance applied between layers to improve adhesion.

- Cold Patch Work

Repair work done using cold materials, particularly in cold weather conditions.

- Dust Palliative

Substances used to stabilize soil and reduce dust emissions on unpaved roads.

- Soil Stabilization

The process of enhancing the physical and chemical properties of soil to support structures.

Reference links

Supplementary resources to enhance your learning experience.