Tests on Bituminous Emulsions

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Viscosity Test

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're going to talk about the viscosity test for bituminous emulsions. This test helps us understand how the emulsion flows, right?

Yes, I think it's related to how easy it is to apply, right?

Exactly! The viscosity is typically checked at temperatures of 25°C or 50°C. Why do you think the temperature might matter?

I guess it affects how thick the emulsion might be?

Yes, the temperature influences the viscosity significantly. So remember, Viscosity = Flow! Let’s move on to the next test.

Storage Stability Test

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, let’s discuss the storage stability test. Why do you think stability during storage is crucial?

If it separates, it might not work well when we apply it!

Precisely! This test is typically conducted over 24 or 5 days. Can anyone think of what we should look for after this period?

I think we need to check if the emulsion stayed mixed together?

Correct! A stable emulsion remains uniform without separating. Now let’s briefly cover the residue by evaporation.

Residue by Evaporation Test

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

The residue by evaporation test is crucial for determining the bitumen content. Why is knowing the bitumen content important?

It helps us gauge the quality and effectiveness of the emulsion!

Exactly! We take a specific amount of emulsion, evaporate the water, and analyze what remains. Next, let's consider how the sieve test works.

Sieve Test and Particle Charge Test

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

With the sieve test, we’re looking to avoid coarse particles that could clog spray nozzles. Why do you think this is important?

If the nozzles clog, it could ruin the application!

Exactly! Now, can anyone explain how the particle charge test is relevant?

It helps us identify if the emulsion is cationic or anionic, right?

Correct! Knowing the charge helps us select the right aggregates for mixing. Finally, let’s talk about the settlement test.

Settlement Test

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

The settlement test checks for uniformity over time. What do you think we are looking for here?

We want to make sure nothing settles too much!

Exactly! It ensures the emulsion remains consistent and usable. To summarize, all these tests help us guarantee the emulsion's quality for applications. Remember: consistency is key!

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

It discusses six primary tests, including viscosity, storage stability, residue by evaporation, sieve test, particle charge test, and settlement test, each designed to assess different aspects of bituminous emulsions for road construction applications.

Detailed

Detailed Summary

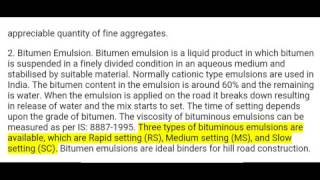

This section delineates the essential tests conducted on bituminous emulsions to ascertain their quality, stability, and suitability for road construction applications. The viscosity test (Saybolt Furol Viscosity) measures the fluid flow characteristics of emulsions, typically performed at temperatures of 25°C or 50°C. The storage stability test ensures that the emulsion does not undergo phase separation during storage, usually examined over periods of 24 to 5 days. The residue by evaporation test identifies the bitumen content by evaporating a fixed sample of the emulsion and analyzing the residue. A sieve test checks for coarse particles that could obstruct spray nozzles during application. The particle charge test determines whether the emulsion is cationic or anionic, which is crucial for its compatibility with different aggregates. Lastly, the settlement test verifies the emulsion's uniformity over time, ensuring it does not exceed specified settling limits. Together, these tests verify the emulsion’s performance and safety for various applications in road construction.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Viscosity Test (Saybolt Furol Viscosity)

Chapter 1 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Determines flow characteristics.

- Conducted at 25°C or 50°C.

Detailed Explanation

The Viscosity Test, specifically the Saybolt Furol Viscosity test, assesses how easily a bituminous emulsion flows. This is crucial for determining how it will perform during application. The test is conducted at two temperatures: 25°C and 50°C. The viscosity reading is indicative of the emulsion's workability; a lower viscosity implies easier application.

Examples & Analogies

Imagine trying to pour syrup versus water. Syrup is thick and flows slowly (high viscosity), while water is thin and flows easily (low viscosity). Just like with these liquids, bituminous emulsions need to be at the right viscosity to be used effectively in road construction.

Storage Stability Test

Chapter 2 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Ensures emulsion does not separate into phases during storage (typically tested over 24 or 5 days).

Detailed Explanation

The Storage Stability Test checks whether the components of the emulsion, namely the bitumen and water, will separate during storage. This test usually runs for 24 to 72 hours. A stable emulsion should maintain its consistency and not separate into distinct layers, which ensures it will work as intended when applied.

Examples & Analogies

Think of a salad dressing made of oil and vinegar. If left to sit, the oil and vinegar will eventually separate. Similarly, an unstable emulsion would not be reliable for use in construction, just like an unstable dressing would not blend well in a salad.

Residue by Evaporation

Chapter 3 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Determines bitumen content.

- A fixed amount is evaporated, and residue is analyzed.

Detailed Explanation

The Residue by Evaporation test is conducted to ascertain the actual content of bitumen in the emulsion. In this test, a measured sample of the emulsion is heated until all the water evaporates, leaving behind the bitumen residue. This residue is then analyzed to confirm the proportion of bitumen, which is critical for ensuring that the emulsion meets specifications.

Examples & Analogies

Imagine making a cup of tea. When you let it steep too long, the water evaporates and leaves behind concentrated flavors in the tea leaves. Similarly, this test makes sure that the right amount of 'flavor' (bitumen) is present in the emulsion after the water evaporates.

Sieve Test

Chapter 4 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Detects coarse particles that could clog spray nozzles.

Detailed Explanation

The Sieve Test is a straightforward method used to identify any coarse particles in the bituminous emulsion. These particles, if present, can obstruct the open spray nozzles during application, affecting the effectiveness of the coating process. A clean emulsion, free of harmful particles, ensures a smooth application.

Examples & Analogies

Think about drinking juice through a straw. If there are pulp particles in the juice, they can clog the straw. Similarly, coarse particles in an emulsion can block the nozzles, so this test helps to keep the 'juice' flowing smoothly during road work.

Particle Charge Test

Chapter 5 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Identifies whether the emulsion is cationic or anionic.

Detailed Explanation

The Particle Charge Test determines the electrical charge of the emulsion particles, which can be either cationic (positively charged) or anionic (negatively charged). This classification is important because it influences how the emulsion interacts with different types of aggregates. Cationic emulsions work better with negatively charged materials and vice versa.

Examples & Analogies

Consider how magnets work. Positive and negative magnets attract each other, while like magnets repel. In a similar way, knowing the charge of the emulsion helps predict which materials it will adhere to best, ensuring a strong bond in construction applications.

Settlement Test

Chapter 6 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Checks uniformity over time; should not settle beyond specified limits.

Detailed Explanation

The Settlement Test assesses how the components of the emulsion settle over time. This test ensures that the emulsion remains uniform and does not separate into layers that exceed acceptable limits. Uniformity is crucial for the performance of the emulsion when it is applied to surfaces.

Examples & Analogies

Think of a layer of sediment in a jar of water. If the sediment settles unevenly, you can’t get a clear read on how deep it is. The settlement test makes sure that bituminous emulsions behave similarly; they should not form uneven layers that complicate their use in road construction.

Key Concepts

-

Viscosity Test: Measures the flow properties and can help predict application performance.

-

Storage Stability: Ensures that emulsions remain usable over time without phase separation.

-

Residue Analysis: Identifies bitumen content, essential for evaluating performance.

-

Sieve Test: Prevents operational issues by ensuring no coarse particles block application.

-

Particle Charge: Determines emulsion compatibility with different aggregates.

-

Settlement Test: Assesses uniformity to ensure consistent application.

Examples & Applications

The viscosity test might show that an emulsion is too thick to be easily applied, which could lead to issues during construction.

If a storage stability test indicates phase separation, the emulsion may need to be reformulated before use.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

For viscosity, let it flow, at 25 or 50, it should glow!

Stories

Imagine a road builder checking the emulsion before work: he pours it and watches if it flows nicely before using it for a strong school driveway.

Memory Tools

Remember 'VSSPS': Viscosity, Storage Stability, Residue, Sieve, Particle charge, Settlement.

Acronyms

Use 'CARS' for tests

Charge

Appearance

Residue

Stability.

Flash Cards

Glossary

- Viscosity Test

A test that determines the flow characteristics of bituminous emulsions.

- Storage Stability Test

A test to ensure the emulsion does not separate into phases during storage.

- Residue by Evaporation

A test that measures the bitumen content by analyzing the residue after evaporation of a fixed sample.

- Sieve Test

A test to detect coarse particles that could clog application equipment.

- Particle Charge Test

A test that identifies whether the emulsion is cationic or anionic.

- Settlement Test

A test to check the uniformity of the emulsion over time.

Reference links

Supplementary resources to enhance your learning experience.