Bituminous Emulsions

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Definition and Importance of Bituminous Emulsions

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Good morning, everyone! Today, we will start with bituminous emulsions. Can anyone tell me what they think a bituminous emulsion is?

Is it a type of liquid used in road construction?

Yes, exactly! A bituminous emulsion is a mixture where bitumen droplets are suspended in water, aided by an emulsifying agent. This combination allows for easier handling and application at ambient temperatures.

Why is that useful?

Great question! It’s beneficial because typical bitumen is very viscous and difficult to work with unless heated. Emulsions make application simpler and more effective, especially in cold weather.

What are the key components in an emulsion?

Excellent inquiry! The main components are bitumen, water, an emulsifier, and sometimes additives for stability or performance. Remember that without the emulsifier, we cannot achieve a stable mixture due to the immiscibility of bitumen and water.

So, is it safe to use?

Yes, in many aspects, emulsions are more environmentally friendly compared to other forms like cutbacks. They also reduce the energy required during application.

To summarize, we learned that bituminous emulsions are vital in road construction, significantly easing the application process. They consist of bitumen, water, emulsifying agents, and can incorporate additives.

Types of Bituminous Emulsions

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s delve deeper into the types of bituminous emulsions. Does anyone remember the factors that classify them?

I think it's based on how fast they set and maybe something about charges?

Correct! They are classified based on both setting time and electrical charge. We have Rapid Setting, Medium Setting, and Slow Setting emulsions.

What does the setting time mean for usage?

Good observation! Rapid Setting emulsions work well for surface dressing as they break quickly. Medium Setting emulsions are preferred for premixing with aggregates, while Slow Setting emulsions remain stable and are mixed with fine aggregates.

What about the charges? How does that affect their use?

Excellent question! Cationic emulsions, which have a positive charge, bond well with negatively charged aggregates like siliceous stones. In contrast, anionic emulsions are suited for basic aggregates like limestone.

So, to recap, emulsions are classified into types based on how quickly they set and their electrical charge, which affects their compatibility with different aggregates.

Preparation and Characteristics of Bituminous Emulsions

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s talk about how we prepare bituminous emulsions. Who can tell me what the process involves?

Do we just mix the bitumen and water?

You're on the right track, but it involves more than that! We start by heating the bitumen to reduce its viscosity, then prepare the water phase with an emulsifier, and finally mix them in a colloidal mill.

What's the colloidal mill for?

Great follow-up! The colloidal mill ensures the bitumen is uniformly dispersed into tiny droplets within the water. This uniformity is crucial for stability.

What characteristics do we measure to ensure quality?

Key characteristics to assess include viscosity, storage stability, and breaking time. For instance, a good emulsion should have a suitable viscosity for application and resist separation over time.

In summary, we learned about the preparation process, including the role of the colloidal mill and important characteristics like viscosity and stability.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The section explains bituminous emulsions which consist of bitumen, water, emulsifiers, and additives. These emulsions are categorized by setting time and charge, making them suitable for various applications in road construction, especially in cold or wet weather conditions.

Detailed

Bituminous Emulsions

Definition

Bituminous emulsions are defined as mixtures in which droplets of bitumen are suspended in water with the aid of emulsifying agents. They are essential in road construction since they allow for easier application and improved performance compared to conventional bitumen, especially at ambient temperatures.

Components of Bituminous Emulsion

- Bitumen: The main binder, making up 40% to 70% of the emulsion.

- Water: Serves as the continuous phase; its quality is vital for the stability of the emulsion.

- Emulsifier (Surfactant): This component helps in forming a stable emulsion.

- Additives: Extra substances may be added to improve the characteristics of the emulsion like stability and workability.

Types of Bituminous Emulsions

Bituminous emulsions are mainly classified based on setting time (Rapid, Medium, Slow) and electrical charge (Cationic and Anionic). This classification aids in selecting the appropriate emulsion for specific road construction applications.

Preparation Process

The preparation of bituminous emulsions involves several steps, starting from heating the bitumen and creating the water phase with emulsifiers, to mixing in a colloidal mill. Maintaining parameters like bitumen content and droplet size is critical to achieve a stable emulsion.

Characteristics and Applications

Characteristics such as viscosity, storage stability, and breaking time are important for assessing the suitability of bituminous emulsions. They find various applications including tack and prime coats, surface dressing, and slurry seals, making them versatile for both hot and cold conditions.

Overall, bituminous emulsions enhance the efficiency of road construction processes, providing significant benefits in terms of application, performance, and environmental safety.

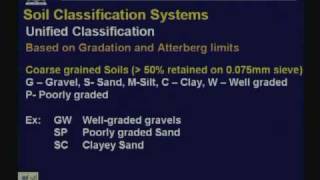

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Definition of Bituminous Emulsion

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

A bituminous emulsion is a mixture in which bitumen droplets are suspended in water with the help of an emulsifying agent. Since bitumen and water are immiscible, the addition of an emulsifier enables the formation of a stable emulsion. Bituminous emulsions are used extensively in road construction, especially for maintenance and cold weather applications.

Detailed Explanation

A bituminous emulsion consists of tiny droplets of bitumen (a sticky black substance) that are mixed into water. Because bitumen doesn't dissolve in water on its own, we need something called an emulsifying agent, which acts like a glue to keep the droplets suspended. This mixture is quite useful in construction, particularly when the weather is cold or when maintaining roads, since it allows the bitumen to be applied without needing to heat it up to high temperatures.

Examples & Analogies

Imagine trying to mix oil into water—you can't just stir them together because they won't blend. However, if you add soap (the emulsifier), the oil can stay dispersed in the water, creating a nice stable mixture. This is exactly what happens with bituminous emulsions, which makes them easier to use in paving roads.

Components of Bituminous Emulsion

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Bitumen: The binder phase, typically 40% to 70% of the emulsion.

- Water: The continuous phase; its quality affects the emulsion stability.

- Emulsifier (Surfactant): A surface-active agent that enables the formation and stability of the emulsion.

- Additives: Sometimes added to improve stability, workability, or performance (e.g., anti-stripping agents, fluxing agents).

Detailed Explanation

Bituminous emulsions are made up of four key components. Firstly, bitumen is the main ingredient that binds everything together, accounting for a significant portion of the mixture (between 40% and 70%). Secondly, water acts as the medium in which the bitumen droplets are suspended. The quality of the water is crucial as it can affect how well the emulsion holds together. The emulsifier helps in blending the bitumen and water, ensuring that they don’t separate. Lastly, additives may be included to enhance the performance of the emulsion, such as improving its stability or making it easier to work with during application.

Examples & Analogies

Think of making a salad dressing: oil (bitumen) doesn't mix with vinegar (water) without adding mustard (emulsifier). The mustard helps the oil and vinegar blend, just like the emulsifier in bituminous emulsion. Additives are like herbs or spices that enhance the flavor of the dressing, making it better for your salad, which in this case is the road!

Types of Bituminous Emulsions

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Emulsions are primarily classified based on their setting time and electrical charge:

(a) Based on Setting Time:

- Rapid Setting (RS): Breaks quickly on contact with aggregate. Suitable for surface dressing.

- Medium Setting (MS): Breaks moderately; ideal for premixing with coarse aggregates.

- Slow Setting (SS): Remains stable for a long time; used in mixing with fine aggregates.

(b) Based on Charge:

- Cationic Emulsions (Positive charge): Interact well with negatively charged aggregates like siliceous stones.

- Anionic Emulsions (Negative charge): Suitable for basic aggregates like limestone.

Detailed Explanation

Bituminous emulsions can be categorized in two main ways: by how quickly they set and by their electrical charge. In terms of setting time, we have rapid, medium, and slow setting types: rapid setting emulsions break quickly when they hit the surface, making them perfect for quick applications like surface dressing. Medium setting emulsions take a moderate amount of time to break, which works well when mixed with bigger aggregates. Slow setting emulsions stay stable longer, which is important when working with fine aggregates. When it comes to charges, cationic emulsions carry a positive charge and are effective with negatively charged materials, while anionic emulsions have a negative charge and work best with materials such as limestone.

Examples & Analogies

Picture this: when you're baking cookies, you can choose to bake them quickly at a high temperature, bake them at a moderate temperature, or let them rise slowly. Each method gives you a different texture and finish, just as different emulsions serve various purposes in construction. The charges are like having either a positively or negatively charged magnet—depending on what you're trying to stick together, you’ll need the right type of magnet for the job!

Key Concepts

-

Bituminous Emulsions: Mixtures of bitumen in water that improve handling and application.

-

Emulsifiers: Agents that stabilize the emulsion allowing bitumen to mix with water.

-

Types Classification: Emulsions are classified by setting time (RS, MS, SS) and electrical charge (Cationic, Anionic).

-

Preparation: Involves heating, emulsifier preparation, and mixing in a colloidal mill.

-

Characteristics: Assessing viscosity, storage stability, and breaking time is essential for ensuring quality.

Examples & Applications

Bituminous emulsions are commonly used for road maintenance and repairs during cold weather when traditional methods might not be effective.

Cationic emulsions are preferred for jobs involving siliceous stones, such as in the construction of new pavement layers.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Bitumen and water make a splash, emulsions come together in a flash!

Stories

Imagine a road construction team on a rainy day. They open the emulsion like a magic potion that works even when everything is wet. Bitumen dances with water, thanks to the emulsifier that binds them!

Memory Tools

Remember 'B-W-E-A' for Bitumen, Water, Emulsifier, Additives – the key components!

Acronyms

EMULSION stands for 'Each Mixture Uniting Liquids Safely In One Niche.' It reminds us of how emulsions blend materials.

Flash Cards

Glossary

- Bitumen

A viscous, black, adhesive substance derived from petroleum, used as a binder in road construction.

- Emulsifier

A surface-active agent that helps to stabilize the mixture of bitumen and water in an emulsion.

- Cationic Emulsion

An emulsion with a positive charge that interacts well with negatively charged aggregates.

- Anionic Emulsion

An emulsion with a negative charge suited for basic aggregates.

- Setting Time

The duration it takes for the emulsion to break and set on aggregates.

Reference links

Supplementary resources to enhance your learning experience.