Preparation of Bituminous Cutbacks

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Bituminous Cutbacks

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today we'll discuss bituminous cutbacks. Can anyone tell me what they think a bituminous cutback is?

Is it a type of bitumen?

Good start! A bituminous cutback is actually created by dissolving bitumen in a solvent. This helps reduce its viscosity, making it easier to work with. Why do you think reducing the viscosity is important?

It makes it easier to apply, especially in cold weather.

Exactly! Now, can anyone name a common solvent used in bituminous cutbacks?

Kerosene?

Correct! Kerosene is one of the solvents used. Remember this with the mnemonic 'Keen Kerosene Keeps it Flowing' to recall how effective it is in reducing viscosity. Also, we need to control the temperature during preparation to avoid hazards.

What happens if it gets too hot?

It can lead to fire risks, which is why monitoring is essential. Great discussion, everyone!

Steps in the Preparation Process

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's get into the steps of preparing bituminous cutbacks. Can anyone repeat the first step?

Heating the bitumen?

Yes! The bitumen needs to be heated to reduce its viscosity. Once heated, what do we do next?

You mix it with the solvent.

Correct! We mix the heated bitumen with the solvent carefully in a controlled environment. Why do you think it's important to do this in a controlled environment?

To prevent accidents and fires?

Exactly! Lastly, what do we do after mixing?

Cool it and store it in sealed containers.

Well done! Always remember, 'Heat, Mix, Cool, Secure' to recall the sequence. Keeping it secure prevents contamination!

Safety and Handling

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

When preparing bituminous cutbacks, safety is crucial. What safety considerations can you think of?

We need to monitor the temperature.

Exactly! The temperature must be controlled to avoid fire hazards. Any other considerations?

Using personal protective equipment?

Exactly! PPE protects you from potential exposure to solvent fumes. Remember, 'Safety First, Last, and Always' to keep safe.

What should we do if something goes wrong?

Have an emergency plan in place! Training for proper responses is vital. Safety is everyone's responsibility!

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Bituminous cutbacks are created by mixing heated bitumen with volatile solvents to reduce viscosity and improve workability. The section emphasizes the importance of controlling temperature during the preparation process to avoid fire hazards and ensure proper storage.

Detailed

Preparation of Bituminous Cutbacks

Bituminous cutbacks are formulated by dissolving bitumen in a volatile solvent such as naphtha or kerosene, improving the fluidity of bitumen at ambient temperatures. The preparation process involves heating bitumen to enhance its consistency and mixing it thoroughly with the specific solvent. Key precautions are emphasized regarding temperature control to mitigate fire hazards during the preparation. Once mixed, the cutback is cooled and stored in sealed containers to maintain its quality and ensure effective application.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Heating and Mixing

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Bitumen is heated and mixed with the desired solvent in a controlled environment.

Detailed Explanation

To prepare bituminous cutbacks, the bitumen needs to be heated first. This reduces its viscosity, meaning it becomes thinner and easier to mix. Then, the heated bitumen is combined with a solvent (like kerosene or naphtha), which helps to further lower the viscosity and make the mixture usable at room temperature. This mixing occurs in a controlled environment to ensure safety and effectiveness.

Examples & Analogies

Think of making a hot chocolate with cocoa powder and milk. When you heat the milk, it becomes much easier to dissolve the cocoa powder. Similarly, heating the bitumen makes it easier to blend with the solvent.

Monitoring Temperature

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Careful monitoring of temperature is necessary to prevent fire hazards.

Detailed Explanation

While preparing bituminous cutbacks, it is crucial to monitor the temperature carefully. Bitumen can catch fire at high temperatures, and the solvents used are also flammable. To ensure safety during the mixing process, specific temperature limits must be observed and controlled so that the process can be conducted without risk of fire.

Examples & Analogies

Imagine cooking oil on a stove; if the temperature gets too high, it can catch fire. Just as you need to monitor the heat while cooking, proper temperature control is vital to avoid dangerous situations when preparing bituminous cutbacks.

Cooling and Storage

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• The resulting liquid is cooled and stored in sealed containers.

Detailed Explanation

After mixing, the liquid bituminous cutback must cool down before storage. Cooling helps to ensure the product is safe to handle and reduces the risk of thermal expansion or pressure buildup in storage containers. Once cooled, the cutback is stored in sealed containers to maintain its quality and prevent any contamination or evaporation of the solvent.

Examples & Analogies

Consider a freshly baked pie that needs to cool before you can cover it with plastic wrap. If you cover it while it's still warm, steam builds up and makes the pie soggy. Likewise, allowing the bituminous cutback to cool before sealing it prevents any issues with storage.

Key Concepts

-

Bituminous Cutbacks: Prepared by dissolving bitumen in solvents to improve application handling.

-

Volatile Solvent: Essential for reducing viscosity of bitumen and enhancing workability.

-

Temperature Control: Critical during preparation to mitigate fire risks.

Examples & Applications

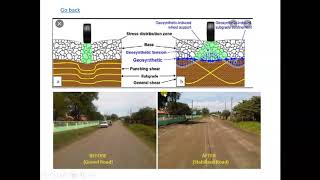

In road maintenance, bituminous cutbacks are often used when working in colder climates, where heating bitumen is impractical.

A construction team uses kerosene as a solvent to prepare a cutback for quick application on a surface.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Heated bitumen so bright, mixed with solvent to take flight.

Stories

Imagine a busy road crew preparing for a cold day; they heat up bitumen, mixing it with kerosene to make it flow like honey, ready to seal the pavement.

Memory Tools

H-M-C-S: Heat, Mix, Cool, Secure - that's how we prepare cutbacks for sure!

Acronyms

V.O.C.

Viscosity

Oil

and Control - remember these for cutback safety!

Flash Cards

Glossary

- Bituminous Cutbacks

Formulated by dissolving bitumen in a volatile solvent to improve fluidity at ambient temperatures.

- Volatile Solvent

A solvent that evaporates easily at normal temperature, used in the formulation of bituminous cutbacks.

- Viscosity

A measure of a fluid's resistance to flow; reduced in bitumen when mixed with a solvent.

Reference links

Supplementary resources to enhance your learning experience.