Characteristics of Bituminous Cutbacks

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Lower Initial Viscosity

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, let's start with the first characteristic of bituminous cutbacks: lower initial viscosity. Can anyone explain what viscosity means in this context?

Isn’t viscosity how thick or thin a liquid is?

Exactly! Lower viscosity means that bituminous cutbacks are thinner compared to pure bitumen, allowing them to flow more easily. Can you think of a situation where this would be beneficial?

In colder temperatures, right? That would help in applying it without needing heat.

Correct! And lower viscosity improves workability overall. It’s easier to mix and apply on the road. Great job! Now, let’s summarize that: bituminous cutbacks help in cold weather applications due to their lower thickness.

Improved Workability

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s talk about improved workability. Can anyone tell me what workability means?

I think it means how easy it is to use the material during construction.

Spot on! Cutbacks enhance workability, making them easier to mix with aggregates. Why do you think this is crucial for road construction?

If it’s easier to work with, we can apply it faster and more uniformly.

Exactly! Efficient application leads to better quality road surfaces. Let’s recap: improved workability means faster and uniform application in road construction.

Setting Time

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, let’s discuss setting time. Who can explain how the type of solvent affects this?

Different solvents evaporate at different rates, right?

That's correct! Rapid curing solvents evaporate quickly, leading to fast setting times, while slow curing solvents take longer. Why would someone choose a slow curing cutback?

Perhaps for areas where slow application is more beneficial, like stabilization?

Exactly! Each type of cutback has its own best use scenario based on the solvent type. To summarize: setting time is crucial in determining the best use of cutbacks depending on the project needs.

Quality Indicators

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Finally, let's talk about the quality indicators of the residual bitumen. What do you think we should look for after the solvent has evaporated?

Penetration and ductility, I think?

Correct! Penetration measures how deep a needle can go into the bitumen, while ductility shows how much it can stretch. Why are these indicators important?

They tell us if the bitumen will perform well under traffic conditions!

Exactly! High penetration and ductility mean better performance. So, our key takeaways are: penetration and ductility are crucial for assessing cutback quality.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Bituminous cutbacks are characterized by their lower viscosity compared to pure bitumen, enhancing workability in road applications. The setting time of cutbacks is contingent upon the solvent used, with important quality indicators including the penetration and ductility of the residual bitumen after evaporation of the solvent.

Detailed

Characteristics of Bituminous Cutbacks

Bituminous cutbacks are essential in road construction, as they allow for easier handling and application of bitumen at ambient temperatures. Unlike pure bitumen, cutbacks exhibit several characteristic features:

1. Lower Initial Viscosity: Cutbacks have a significantly reduced viscosity, facilitating easier application and enabling usage in colder conditions.

2. Improved Workability: The reduced viscosity makes them simpler to work with, optimizing mixing and application processes.

3. Setting Time: The time it takes for a cutback to set is determined by the type of solvent used. Rapid curing, medium curing, and slow curing cutbacks have varying evaporation rates, impacting their practical use.

4. Key Quality Indicators: After the solvent evaporates, the characteristics of the remaining bitumen, notably its penetration and ductility, are critical for ensuring performance. The ability of this residue to stretch without breaking and the penetration depth are key indicators of cutback quality.

In summary, understanding the characteristics of bituminous cutbacks is crucial for their effective application in various road construction scenarios.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Lower Initial Viscosity

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Lower initial viscosity compared to pure bitumen.

Detailed Explanation

Bituminous cutbacks are designed to have a lower initial viscosity than pure bitumen. This means they are less thick and easier to work with when applied at ambient temperatures. The lower viscosity allows for easier spreading and application on surfaces. This characteristic is crucial in ensuring that the material can be smoothly applied without requiring extreme heat.

Examples & Analogies

Think of bituminous cutbacks like a well-mixed pancake batter, which is fluid and easy to pour. In contrast, pure bitumen would be like a lump of sticky dough that you struggle to spread out. Just as the batter makes it easier to create perfect pancakes, the lower viscosity of cutbacks makes applying them on roads easier and more efficient.

Improved Workability at Lower Temperatures

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Improved workability at lower temperatures.

Detailed Explanation

Bituminous cutbacks are specifically designed to remain workable even at cooler temperatures, unlike traditional bitumen, which can become very thick and difficult to handle when cold. This feature allows construction and maintenance work to continue under various weather conditions, especially in cooler climates.

Examples & Analogies

Imagine trying to spread butter on toast when it’s cold from the fridge. It’s tough and may tear the bread. Now, if you let the butter sit at room temperature, it becomes spreadable. Bituminous cutbacks are like that warmed-up butter, maintaining a workable consistency regardless of the weather, which is critical for timely road repairs.

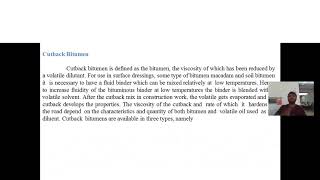

Setting Time Determined by Solvent Type

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Setting time determined by solvent type.

Detailed Explanation

The setting time of a bituminous cutback refers to how quickly it forms a solid layer after application. This setting time is heavily influenced by the type of solvent used in the cutback. Rapid curing solvents lead to faster setting times, while slower solvents take longer to evaporate, thus prolonging setting time. This control over the setting time allows for flexibility depending on the specific requirements of a project.

Examples & Analogies

Think of making a smoothie with different types of ice. If you use crushed ice, your smoothie blends quickly and thickens faster. If you use ice cubes, it takes longer to blend and thicken. Similarly, using a fast-evaporating solvent for cutbacks ensures a quicker setup compared to a slow-evaporating solvent.

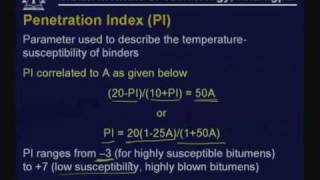

Key Quality Indicators: Penetration and Ductility

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Penetration and ductility of the residue are key quality indicators.

Detailed Explanation

Two important quality indicators of the residue left after the solvent evaporates are penetration and ductility. Penetration tests measure how far a standard needle can penetrate the bitumen at a specific temperature, indicating its hardness or softness. Ductility measures the material's ability to stretch without breaking under stress. These indicators help ensure that the cutback will perform well under traffic and environmental conditions.

Examples & Analogies

Picture a rubber band. If it stretches easily without snapping, it has good ductility. If it resists stretching and breaks easily, it does not. Similarly, a good quality cutback will have an ideal balance of penetration and ductility, ensuring it can handle the wear and tear of traffic and weather without failing.

Key Concepts

-

Lower Initial Viscosity: Allows for easier handling and application.

-

Improved Workability: Enhances the efficiency of construction processes.

-

Setting Time: Influenced by the type of solvent used, affecting the application timeline.

-

Quality Indicators: Penetration and ductility are crucial for assessing performance.

Examples & Applications

Using rapid curing cutbacks for surface treatments allows for efficient and quick application, especially in urban settings.

Medium curing cutbacks are often preferred when mixing with coarse aggregates to create a stable base for paving.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Cutbacks are smooth, with viscosity low, making application easy, up they go!

Stories

Imagine a cold day on a construction site where workers struggle with thick bitumen. Then comes a magical potion—bituminous cutback! It flows easily, helping them finish their job quickly.

Memory Tools

P-D for quality: Remember P for Penetration and D for Ductility!

Acronyms

W.H.I.S.P. – Workability, High quality, Improved flow, Setting time, Penetration.

Flash Cards

Glossary

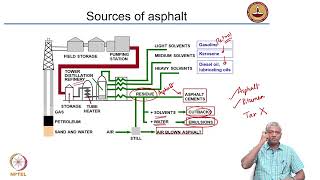

- Bituminous Cutback

A mixture of bitumen dissolved in a volatile solvent to enhance its fluidity and reduce viscosity for easier application.

- Viscosity

A measure of a fluid's thickness or resistance to flow.

- Workability

The ease with which a material can be manipulated or used during construction.

- Setting Time

The time taken for a material to cure and harden after application.

- Quality Indicators

Parameters used to evaluate the performance of the residual bitumen after solvent evaporation, including penetration and ductility.

Reference links

Supplementary resources to enhance your learning experience.