Definition - 11.9.1

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Understanding Cutbacks

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're going to talk about bituminous cutbacks. Who can tell me what a cutback is?

A cutback is like a thinner version of bitumen, right?

Exactly! Cutbacks are made by dissolving bitumen in a volatile solvent to reduce its viscosity. Does anyone know why we do this?

It helps it be more fluid, especially in colder temperatures!

Perfect! It enhances fluidity for application without needing heating. So remember: C for Cutback, C for Cold! Who can explain what happens after application?

The solvent evaporates, leaving the bitumen behind!

Yes! And that's crucial for creating a durable film on the surface.

Wait, what kind of solvents can we use for cutbacks?

Great question! Common solvents are naphtha and kerosene. Remember this acronym: NK for Naphtha and Kerosene!

So to summarize: Bituminous cutbacks, made by dissolving bitumen in volatile solvents, improve application and promote smoother cold mixtures.

Application of Cutbacks

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s explore where we can use these cutbacks. Why do you think they are helpful in road construction?

They can be applied in cold conditions, right?

Exactly! They find their place in cold mixes, tack coats, and even prime coats. Who can tell me more about the benefits?

They are quick-drying due to the evaporation of solvents. It speeds up the process!

Yes! The rapid curing helps save time. Remember our mnemonic—'FLIC': Fast, Low-Viscosity, Improves Cold applications!

What about environmental concerns? Are they safe to use?

Good point! While they offer benefits, cutbacks can release VOCs, so we must handle them safely. Always wear appropriate PPE—personal protective equipment!

To summarize: Bituminous cutbacks help us in cold conditions and offer quick drying, but we must be cautious about safety.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Bituminous cutbacks are created by dissolving bitumen in a volatile solvent to reduce its viscosity and improve fluidity. The solvent evaporates post-application, leaving behind a durable bituminous layer. This approach is particularly useful for applications in cooler conditions.

Detailed

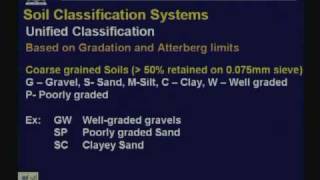

Bituminous cutbacks are essential in road construction, where the viscosity of traditional bitumen presents challenges, especially in cooler environments. They are formulated by dissolving bitumen in a volatile solvent such as naphtha or kerosene. This mixture enhances fluidity at ambient temperatures, streamlining the application process. After the cutback is applied to a surface, the solvent evaporates, resulting in a robust bituminous film. This innovative process allows for effective surface treatments and other applications where traditional bitumen might not perform optimally, demonstrating the importance of cutbacks in enhancing the versatility of bitumen in the field.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Solvent Evaporation

Chapter 1 of 1

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

After application, the solvent evaporates, leaving behind a bituminous film.

Detailed Explanation

Once bituminous cutbacks are applied to a surface, the volatile solvent they contain begins to evaporate into the air. This process is crucial because, after the solvent is gone, what remains is a durable bituminous film that provides the desired adhesive qualities necessary for road construction and maintenance.

Examples & Analogies

Think of applying a layer of paint that has a solvent in it. When you paint a wall, the liquid evaporates over time, leaving behind a solid color on the surface. Similarly, when you apply bituminous cutbacks, the solvent evaporates, leaving a sturdy layer of bitumen that holds things together well.

Key Concepts

-

Bituminous Cutback: A formulation of bitumen and solvent aimed at achieving lower viscosity.

-

Volatile Solvent: A key component that evaporates after application, leaving behind bitumen.

Examples & Applications

Using rapid curing cutbacks for quick repairs on highways during winter.

Applying medium curing cutbacks in paving mixtures for better adhesion in colder areas.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Cut back that bitumen with a solvent fast, It flows so nice, it'll dry at last.

Stories

Imagine a chilly day at a construction site. The workers can't apply heavy bitumen without heating, but then they find cutbacks. With a magical solvent, they could apply it easily, and soon the road was ready after the solvent disappeared!

Memory Tools

Remember 'RMC' - Rapid, Medium, Slow for curing times of Cutbacks!

Acronyms

NK

Naphtha and Kerosene are the common solvents in cutbacks!

Flash Cards

Glossary

- Bituminous Cutback

A mixture where bitumen is dissolved in a volatile solvent to reduce viscosity and enhance fluidity for application.

- Volatile Solvent

A substance that evaporates quickly at room temperature, used in bituminous cutbacks to enhance fluidity.

Reference links

Supplementary resources to enhance your learning experience.