Tests on Bituminous Cutbacks

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Distillation Test

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we will start with the distillation test. This test is essential for evaluating the percentage of volatile solvent in bituminous cutbacks. Can anyone tell me why knowing this percentage is important?

Is it to classify the cutback into rapid, medium, or slow curing types?

Exactly! It's crucial because it helps in determining the appropriate applications for the cutback based on its curing time. The more volatile the solvent, the faster it cures. Can anyone name one of the types of curing?

Rapid Curing, right?

Correct! The RC type uses highly volatile solvents. Let's remember the acronym 'VSR' which stands for Viscosity, Solvent, and Rate of curing for evaluating our bituminous cutbacks. What do you think we gather from this test?

We get information about how quickly it can be used on site?

Very true! It guides us on how to manage its application properly.

Penetration Test

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next is the penetration test. Can anyone explain what this test measures?

It measures how deep a needle goes into the residual bitumen?

Right! This helps us assess the consistency of the residual bitumen. Why is this information necessary?

It could indicate whether the bitumen is too hard or too soft?

Exactly! Hard bitumen might crack, while soft bitumen may not provide enough stability. Remember the phrase 'Penetrate to Assess' to keep this test in mind.

Are there specific standards for penetration values?

Good question! Yes, there are standard values that define whether the bitumen is suitable for use.

Ductility Test

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let's talk about the ductility test. What does this test tell us about the bitumen?

It measures how flexible the bitumen is?

Exactly! It's important because flexible bitumen can adapt to temperature fluctuations without cracking. Can someone provide a situation where ductility matters?

In places with extreme temperatures?

Correct! Remember the mnemonic 'Ductile = Durable'. A ductile bitumen helps in the longevity of the pavement.

Flash Point Test

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Moving on to the flash point test. Why do you think this test is performed?

To check if the solvent is flammable?

Exactly! It helps assess the safety and fire risk of handling the cutback. Why is understanding flash points important?

So we can take proper precautions during application?

That's right! Remember to think 'Safety First - Check the Flash'.

Viscosity Test

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Lastly, we have the viscosity test. What aspect does this test cover?

It measures how thick or thin the cutback is?

Correct! Viscosity affects how easily we can apply the cutback. Can someone tell me why we need to ensure good viscosity?

If it’s too thick, it won’t spray well?

That's a great point! A balance is needed for effective handling and application. Use the phrase 'Good Flow, Good Show' to remember viscosity's importance.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

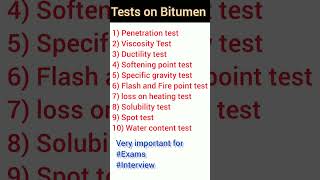

The section outlines key tests used to evaluate bituminous cutbacks, focusing on aspects such as distillation, penetration, ductility, flash point, and viscosity. Each test plays a crucial role in determining the characteristics and suitability of bituminous cutbacks for different applications.

Detailed

Tests on Bituminous Cutbacks

This section details the essential tests used to evaluate bituminous cutbacks, which are important in determining their quality and performance in construction applications. The tests outlined include:

- Distillation Test: This test measures the percentage of volatile solvent in the cutback, helping to classify it into categories such as rapid curing (RC), medium curing (MC), or slow curing (SC).

- Penetration Test: This test assesses the consistency of the residual bitumen by measuring how far a standard needle penetrates the bitumen at a specified temperature.

- Ductility Test: This evaluates the ability of the residual bitumen to stretch without breaking, providing insights into its flexibility and workability.

- Flash Point Test: A critical safety measure, this test measures the temperature at which the vapors of the solvent can ignite, thus assessing the fire risk associated with handling the cutbacks.

- Viscosity Test: This measures how easily the cutback flows under certain conditions, which is essential for determining how it can be handled and applied in the field.

Each of these tests serves to ensure that the bituminous cutback meets the required standards for performance and safety, making them vital in the construction and infrastructure sector.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Distillation Test

Chapter 1 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Distillation Test

• Measures the percentage of volatile solvent.

• Helps determine cutback classification (RC, MC, SC).

Detailed Explanation

The Distillation Test is used to measure how much volatile solvent remains in the bituminous cutback. When a sample is heated, the solvent evaporates, and the amount that evaporates indicates the type of cutback it is: Rapid Curing (RC), Medium Curing (MC), or Slow Curing (SC). The percentage of solvent left after distillation helps in understanding the characteristics of the cutback and its suitability for specific applications.

Examples & Analogies

Think of the distillation test like boiling a pot of water with pasta. As the water boils away, you can see how much is left. Just like you wouldn't want your pot to run dry while cooking, we need to know how much solvent is in the cutback to ensure it performs correctly when applied.

Penetration Test

Chapter 2 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Penetration Test

• Indicates consistency of residual bitumen.

Detailed Explanation

The Penetration Test measures how deeply a standard needle penetrates into the residual bitumen after the solvent has evaporated. This test gives an indication of the consistency and hardness of the residual bitumen. A higher penetration value indicates softer bitumen, while a lower value indicates harder bitumen. This information is crucial for determining how the bitumen will perform as a binder in paving applications.

Examples & Analogies

Imagine pushing your finger into a soft piece of cake versus a hard cookie. The cake will give way easier (similar to softer bitumen), while the cookie might resist that pressure more (like harder bitumen). This test helps us know what type of 'cake' we are working with in construction.

Ductility Test

Chapter 3 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Ductility Test

• Measures the ability of residue to stretch without breaking.

Detailed Explanation

The Ductility Test evaluates how flexible and stretchable the residual bitumen is after the solvent has evaporated. The test involves stretching a sample until it breaks and measuring the distance it stretches. Good ductility means the bitumen can handle movement and stress without cracking, which is important for maintaining road integrity under various conditions.

Examples & Analogies

Think of ductility like stretching a rubber band. A good rubber band will stretch far without snapping, but if it’s too brittle, it breaks easily. The same principle applies to bitumen; if it’s ductile enough, it can endure traffic and weather changes without failing.

Flash Point Test

Chapter 4 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Flash Point Test

• Assesses safety and fire risk.

Detailed Explanation

The Flash Point Test measures the temperature at which the vapors of the cutback ignite when exposed to an open flame. This test is vital for safety, as bituminous cutbacks contain volatile solvents that can be flammable. By knowing the flash point, workers can take appropriate safety measures when handling and storing these materials.

Examples & Analogies

Imagine cooking with oil; if you heat it too much, it can catch fire. The flash point is the cooking temperature you need to be cautious about. It reminds workers to avoid temperatures that could cause the vapors to ignite while working with cutbacks.

Viscosity Test

Chapter 5 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Viscosity Test

• Important for handling and application.

Detailed Explanation

The Viscosity Test measures the thickness or flow characteristics of the bituminous cutback. A low viscosity means the cutback flows easily and is manageable during application, while a high viscosity implies that it might be too thick to work with effectively. This characteristic influences how the cutback can be applied and its performance on roads.

Examples & Analogies

Think about pouring syrup versus pouring water. Syrup is thick (high viscosity) and flows slowly, while water is thin (low viscosity) and pours easily. Just like in cooking, the right viscosity in bituminous cutbacks helps ensure smoother application during road construction.

Key Concepts

-

Distillation Test: Measures the percentage of volatile solvent in cutbacks.

-

Penetration Test: Indicates the consistency and relative hardness of residual bitumen.

-

Ductility Test: Evaluates the flexibility of residual bitumen.

-

Flash Point Test: Determines the safety of handling cutbacks based on flammability.

-

Viscosity Test: Assesses the flow characteristics of the bitumen.

Examples & Applications

A distillation test yielding 60% volatiles may indicate a rapid curing cutback.

A penetration value of 40 dmm could suggest that the residual bitumen has a moderately hard consistency.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

To keep it right and safe each day, we must check the flash and play.

Stories

Imagine a team of road builders. They cross a river of fire—this symbolizes the careful handling they must do around volatile solvents.

Memory Tools

Remember ‘P-D-V-F’ for the tests: Penetration, Ductility, Viscosity, Flash point.

Acronyms

VSR = Viscosity, Solvent, Rate of curing for evaluating bituminous cutbacks.

Flash Cards

Glossary

- Distillation Test

A test that measures the percentage of volatile solvents in bituminous cutbacks for classification.

- Penetration Test

A test that determines the depth a standard needle penetrates into the residual bitumen, indicating its consistency.

- Ductility Test

A measurement of how much the residual bitumen can stretch without breaking.

- Flash Point Test

A test that assesses the temperature at which vapors of a solvent can ignite, indicating safety risks.

- Viscosity Test

A test measuring how easily the cutback flows, which is essential for handling and application.

Reference links

Supplementary resources to enhance your learning experience.