Bituminous Emulsions and Cutbacks

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Bituminous Emulsions

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're discussing bituminous emulsions, essential in road construction for easy handling of bitumen. Does anyone know why we need to modify bitumen?

To make it easier to apply without heating, right?

Exactly! Bitumen is usually too viscous at ambient temperatures. Emulsions help by suspending bitumen in water, thanks to an emulsifying agent. Does anyone remember the key components of an emulsion?

Isn’t it bitumen, water, and an emulsifier?

And additives, too, right?

Correct! The emulsifier assists in forming a stable mixture. Let’s memorize it as WBEA—Water, Bitumen, Emulsifier, Additives. Great job, everyone!

Types of Bituminous Emulsions

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, let’s look at the types of bituminous emulsions. Can anyone mention how they are classified?

I think it's by setting time and electrical charge.

Good! We have Rapid, Medium, and Slow setting types. And regarding charge, cationic and anionic. Can someone give me examples of when to use them?

I know rapid setting is good for surface dressing!

And slow setting for mixing with fine aggregates.

Exactly! Remember RS for Rapid and SS for Slow, which stands for 'Surface' and 'Stable' respectively. Great teamwork!

Preparation of Bituminous Emulsions

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s talk about how we prepare bituminous emulsions. What’s the first step?

Heating the bitumen to reduce its viscosity!

Right! After that, we prepare the water phase with emulsifiers. Can someone outline the remaining steps?

Then we mix everything in a colloidal mill, right?

Correct! And we store the emulsion safely afterwards. Remember the steps with the acronym P-WMST (Prepare, Water, Mix, Store).

Testing Bituminous Emulsions

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

It’s crucial to test bituminous emulsions before use. What tests can we perform?

Viscosity test, like Saybolt Furol?

And the storage stability test?

Great points! The tests ensure that the emulsion maintains its properties over time. Let's remember these as VST (Viscosity, Stability, Type).

Advantages and Limitations of Bituminous Emulsions

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

To wrap up, let’s discuss the advantages and limitations of bituminous emulsions. What benefits can you think of?

They can be applied in wet or cold conditions, right?

And they require no heating!

Exactly! Now, what are some limitations?

Limited shelf life?

And they need skilled handling!

Great observations! Remember the acronym AL—Advantages and Limitations to summarize our discussion.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The section discusses the significance of bituminous emulsions and cutbacks in road construction, detailing their definitions, components, various types, preparation methods, testing procedures, and applications. Emulsions and cutbacks serve to improve the handling, application, and performance of bitumen in different conditions, making them vital in modern road engineering.

Detailed

Detailed Summary

Introduction

In road construction, bitumen is a crucial binder noted for its adhesive and waterproofing capabilities. However, its high viscosity necessitates heating for application, creating challenges. To mitigate this, bituminous emulsions and cutbacks are employed as practical alternatives.

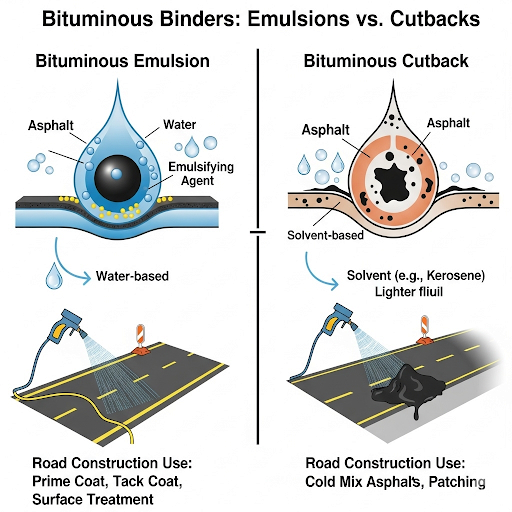

Bituminous Emulsions

Definition

Bituminous emulsions are stable mixtures of bitumen droplets suspended in water, facilitated by an emulsifying agent.

Components

- Bitumen: 40%-70% of the emulsion.

- Water: Affects stability.

- Emulsifier: Enhances stability.

- Additives: To improve performance.

Types of Emulsions

- Based on Setting Time:

- Rapid Setting (RS): Quick setting for surface dressing.

- Medium Setting (MS): Suitable for premixing.

- Slow Setting (SS): Long-stable, used with fine aggregates.

- Based on Charge:

- Cationic (Positive charge): Works with negatively charged aggregates.

- Anionic (Negative charge): Best for basic aggregates.

Preparation

Utilizes a colloidal mill for mixing heated bitumen and water with emulsifier. Stability parameters, including droplet size, pH, and bitumen content, must be controlled.

Characteristics

Assess factors like viscosity, storage stability, residue properties, and breaking time for effective use.

Testing Methods

Involves tests for viscosity, stability, residue, sieve, particle charge, and settlement.

Applications

Used in tack coats, prime coats, slurry seals, and dust control among others, highlighting versatility and efficiency.

Limitations

Includes considerations such as limited shelf life and the need for skilled handling.

Bituminous Cutbacks

Definition

Cutbacks are made by dissolving bitumen in volatile solvents to lower viscosity for easier application.

Types of Cutbacks

- Rapid Curing (RC): Quick evaporation for surface treatments.

- Medium Curing (MC): Suitable for premixes.

- Slow Curing (SC): For prime coats/stabilization.

Preparation

Bitumen mixed with solvents under controlled conditions, including safety precautions against fire hazards.

Characteristics

Features lower viscosity, improved workability, and dependence on solvent type for setting time.

Testing Methods

Involves distillation, penetration, ductility, flash point, and viscosity tests.

Applications

Useful in tack and prime coats, cold patch work, dust control, and soil stabilization.

Limitations

Include environmental concerns due to VOC emissions and specific storage requirements.

Comparison of Emulsions and Cutbacks

The section concludes with a comparison, addressing aspects such as environmental impact, energy requirements, storage stability, and mechanism of breaking.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Introduction to Bituminous Emulsions and Cutbacks

Chapter 1 of 18

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

In road construction, bitumen is widely used as a binder due to its excellent adhesive and waterproofing properties. However, the application of bitumen at ambient temperatures can be challenging due to its high viscosity and requirement for heating. To address this, bituminous emulsions and cutbacks are used as alternatives. These modified forms allow for easier handling, better penetration, and energy savings. This chapter discusses the preparation, classification, characteristics, uses, and testing of bituminous emulsions and cutbacks.

Detailed Explanation

Bitumen is a common material used in road construction because it sticks well to surfaces and prevents water from damaging the road structure. However, using bitumen at normal temperatures can be difficult because it's very thick and needs to be heated to flow easily. To solve this problem, engineers often use two alternatives: bituminous emulsions and cutbacks. These options help make the bitumen easier to handle and apply on the road, penetrate better into surfaces, and save energy since they don't require heating. This section will cover how these materials are prepared, classified, and tested, as well as their characteristics and uses in road construction.

Examples & Analogies

Think of bitumen like honey. While honey is great for sticking things together, it's too thick to use easily right out of the jar, which is similar to how bitumen is hard to work with when cold. By using emulsions and cutbacks, engineers can make this honey-like substance flow better, just as you might warm honey to drizzle it over pancakes.

Definition of Bituminous Emulsions

Chapter 2 of 18

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

A bituminous emulsion is a mixture in which bitumen droplets are suspended in water with the help of an emulsifying agent. Since bitumen and water are immiscible, the addition of an emulsifier enables the formation of a stable emulsion. Bituminous emulsions are used extensively in road construction, especially for maintenance and cold weather applications.

Detailed Explanation

A bituminous emulsion is essentially a mixture where tiny droplets of bitumen are dispersed in water, which normally wouldn’t mix well. To create this emulsion, an emulsifying agent is added; this substance helps the bitumen droplets stay mixed with the water, leading to a stable product. These emulsions are especially useful in road construction as they can be applied even in cold temperatures and during maintenance when using pure bitumen would be impractical.

Examples & Analogies

Imagine shaking a bottle of salad dressing with oil and vinegar; without something to help them mix, they will just separate. The emulsifier in our drink helps keep the oil droplets suspended in the vinegar, just like how the emulsifier keeps bitumen and water mixed for road applications.

Components of Bituminous Emulsion

Chapter 3 of 18

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Bitumen: The binder phase, typically 40% to 70% of the emulsion.

- Water: The continuous phase; its quality affects the emulsion stability.

- Emulsifier (Surfactant): A surface-active agent that enables the formation and stability of the emulsion.

- Additives: Sometimes added to improve stability, workability, or performance (e.g., anti-stripping agents, fluxing agents).

Detailed Explanation

A bituminous emulsion is made up of several key components:

1. Bitumen: This is the main ingredient, making up between 40% and 70% of the emulsion, and it acts as the binder that holds everything together.

2. Water: This serves as the base or continuous phase; its purity and quality are crucial because dirty or contaminated water can disrupt the stability of the emulsion.

3. Emulsifier: Known as a surfactant, this ingredient is essential in helping mix the immiscible bitumen and water. It keeps the mixture stable so the bitumen doesn’t separate.

4. Additives: These are optional extra ingredients added to enhance certain properties, such as making the emulsion more stable or easier to work with.

Examples & Analogies

Think of making a smoothie. The fruits (bitumen) need a liquid (water) to blend well. If you don't have something to help combine them (like an emulsifier), the fruit and juice will just separate again. Additives can be seen as extra flavorings that enhance the smoothie without changing its basic functionality.

Types of Bituminous Emulsions

Chapter 4 of 18

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Emulsions are primarily classified based on their setting time and electrical charge:

(a) Based on Setting Time:

- Rapid Setting (RS): Breaks quickly on contact with aggregate. Suitable for surface dressing.

- Medium Setting (MS): Breaks moderately; ideal for premixing with coarse aggregates.

- Slow Setting (SS): Remains stable for a long time; used in mixing with fine aggregates.

(b) Based on Charge:

- Cationic Emulsions (Positive charge): Interact well with negatively charged aggregates like siliceous stones.

- Anionic Emulsions (Negative charge): Suitable for basic aggregates like limestone.

Detailed Explanation

Bituminous emulsions can be categorized in two main ways:

1. By Setting Time:

- Rapid Setting (RS) Emulsions: These emulsions dry quickly when they come into contact with aggregates, making them great for applications like surface dressing where a fast set is crucial.

- Medium Setting (MS) Emulsions: They have a moderate setting time, making them suitable for mixing with coarser aggregates, allowing better workability.

- Slow Setting (SS) Emulsions: These remain stable for longer periods, which is useful when working with finer aggregates as it gives more time for application.

2. By Electrical Charge:

- Cationic Emulsions: These have a positive charge and bond well with negatively charged aggregates such as siliceous stones, like quartz.

- Anionic Emulsions: These carry a negative charge and work well with positive aggregates, like limestone, improving adherence and interaction.

Examples & Analogies

Think about how you can use different types of glue for different materials. Just like you would choose a super glue for quick fixes or a wood glue for more time-consuming projects, the type of emulsion is selected based on how quickly it sets and what materials you’re working with—whether they’re like siliceous stones or limestone.

Preparation of Bituminous Emulsions

Chapter 5 of 18

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Bituminous emulsions are manufactured using a colloidal mill where bitumen is mechanically sheared into small droplets and mixed with water containing the emulsifying agent.

Steps in Preparation:

1. Heating of bitumen to reduce viscosity.

2. Preparation of water phase with emulsifier.

3. Introduction into the colloidal mill for mixing.

4. Collection and storage of the emulsion in tanks.

Important parameters such as bitumen content, droplet size, and pH are controlled to ensure emulsion stability.

Detailed Explanation

Creating bituminous emulsions involves a series of steps designed to ensure effectiveness and stability:

1. Heating the Bitumen: First, the bitumen is heated to make it less thick and more manageable. This is important because when it's warm, it can be more easily mixed into smaller droplets.

2. Preparing the Water Phase: While the bitumen is heating, water mixed with the emulsifier (the substance that helps keep the oil and water combined) is prepared.

3. Colloidal Mill Mixing: The next step involves putting the heated bitumen and prepared water into a colloidal mill. Here, the bitumen is chopped into tiny droplets, which get mixed thoroughly with the water and emulsifier.

4. Storage: Finally, the mixed emulsion is collected and stored in tanks. During this process, important factors like the amount of bitumen, size of the droplets, and even pH levels are monitored to ensure the final product is stable and effective.

Examples & Analogies

Making an emulsion is like cooking a sauce. Imagine you want to make the perfect salad dressing: first, you heat your ingredients to get them to blend better (heating the bitumen), then you mix them with your base (the water and emulsifier). When you whisk everything together to emulsify it in a bowl (the colloidal mill), you’ve got the right sauce to pour over your salad!

Characteristics of Bituminous Emulsions

Chapter 6 of 18

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Viscosity: Should be appropriate for spraying or mixing.

- Storage Stability: Should resist separation of bitumen and water over time.

- Residue Properties: After breaking, the residual bitumen must have good adhesion, ductility, and penetration values.

- Breaking Time: Indicates how fast the emulsion breaks and sets on aggregate.

Detailed Explanation

For bituminous emulsions to be effective, they must exhibit certain characteristics:

- Viscosity: This refers to how thick or fluid the emulsion is. The viscosity needs to be right so that it can be easily sprayed or mixed without being too runny or too thick.

- Storage Stability: A good emulsion should not separate over time; bitumen needs to remain mixed with water for it to be used successfully later on.

- Residue Properties: After the emulsion dries, the bitumen left behind should have certain qualities—like the ability to stick well (adhesion) and resist breaking when stretched (ductility). This ensures it performs well on the road.

- Breaking Time: This indicates how quickly the emulsion turns back into a solid state after application, which is crucial for knowing when the road can be opened for traffic.

Examples & Analogies

Think of baking bread. The ingredients (flour, water, yeast) must have just the right consistency (viscosity) to rise properly. If you leave the dough out too long, it might separate (storage stability) or not bake correctly (residue properties). Similarly, an emulsion must maintain the right qualities for effective use in construction.

Tests on Bituminous Emulsions

Chapter 7 of 18

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Viscosity Test (Saybolt Furol Viscosity): Determines flow characteristics.

- Storage Stability Test: Ensures emulsion does not separate into phases during storage (typically tested over 24 or 5 days).

- Residue by Evaporation: Determines bitumen content. A fixed amount is evaporated, and residue is analyzed.

- Sieve Test: Detects coarse particles that could clog spray nozzles.

- Particle Charge Test: Identifies whether the emulsion is cationic or anionic.

- Settlement Test: Checks uniformity over time; should not settle beyond specified limits.

Detailed Explanation

To ensure that bituminous emulsions meet quality and performance standards, several tests are conducted:

1. Viscosity Test: This test measures how smoothly the emulsion flows, giving insight into its application properties.

2. Storage Stability Test: This test checks whether the emulsion separates during storage. It usually involves observing the emulsion over a period to see if it stays mixed.

3. Residue by Evaporation: This test measures how much bitumen is present by evaporating a sample and analyzing what's left behind; important for understanding content.

4. Sieve Test: This test screens for large particles in the emulsion that could clog application equipment like spray nozzles.

5. Particle Charge Test: This identifies whether the emulsion is cationic (positively charged) or anionic (negatively charged), which tells how it’ll react with different aggregates.

6. Settlement Test: This checks for consistency over time, making sure the emulsion doesn’t settle out of suspension or separate in storage.

Examples & Analogies

If you think of making a smoothie again, you’d check if it flows well (viscosity), ensure the ingredients don’t separate when sitting (storage stability), and taste it to see if it has the right consistency (residue by evaporation). Tests help determine if your emulsions are just as good before applying to roads.

Uses of Bituminous Emulsions

Chapter 8 of 18

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Tack Coat: For bonding between layers.

- Prime Coat: For low-strength subgrades.

- Surface Dressing: For maintenance of existing roads.

- Slurry Seal and Microsurfacing

- Cold Mixes: In areas without heating facilities.

- **Dust Control and Soil Stabilization

Detailed Explanation

Bituminous emulsions have a wide array of uses in road construction, including:

- Tack Coat: These are thin layers applied between different layers of asphalt to help them bond together.

- Prime Coat: They prepare weak and low-strength subgrades or layers, helping projects get a strong foundation.

- Surface Dressing: Emulsions are used to maintain road surfaces, providing a protective overlay.

- Slurry Seal and Microsurfacing: These techniques involve spreading a thin layer of emulsion mixed with aggregates to rejuvenate and protect existing surfaces.

- Cold Mixes: In places where it’s challenging to heat materials for application, emulsions allow cold mixes to be used without heating.

- Dust Control and Soil Stabilization: Emulsions can also help in suppressing dust on unpaved roads and stabilizing soil in various applications.

Examples & Analogies

Imagine a painter using different brushes and techniques; each serves a purpose in creating the final piece. Here, bituminous emulsions are like those different tools used in the road construction 'painting' process—each serves a specific function to achieve the strongest, most durable road.

Advantages of Bituminous Emulsions

Chapter 9 of 18

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Can be used in wet or cold conditions.

- No heating required during application.

- Environmentally safer than cutbacks.

- Lower energy consumption during application.

- Suitable for cold mix and patch repair.

Detailed Explanation

Bituminous emulsions come with several significant advantages:

- They can be applied even in damp or cold weather, which is a huge bonus for construction schedules especially in regions with unpredictable climates.

- Their application does not require heating, which saves time and equipment costs.

- Compared to cutbacks, emulsions are more environmentally friendly, releasing fewer harmful substances into the air and ground.

- Additionally, they help save on energy costs as no heating is necessary for emulsification.

- Emulsions are particularly fitting for cold mix applications and patch repairs where traditional methods may not work as effectively.

Examples & Analogies

Using bituminous emulsions is like having a universal remote for your TV; it simplifies things, allows flexibility (adapting to wet conditions), and cuts down on additional clutter (no need for heating equipment). They streamline the entire road construction process, making it easier to get the job done under various conditions.

Limitations of Bituminous Emulsions

Chapter 10 of 18

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Limited shelf life.

- Requires skilled handling.

- May not be effective in water-logged areas.

- Storage tanks must be cleaned periodically to avoid contamination.

Detailed Explanation

While bituminous emulsions offer many advantages, there are also certain limitations:

- Limited Shelf Life: Emulsions do not last indefinitely, and over time they can degrade or separate, requiring proper storage practices.

- Skilled Handling Required: Skilled workers are essential for mixing and applying emulsions correctly, as improper handling can lead to application failures.

- Water-logged Areas: In areas prone to excessive moisture, emulsions may not bond effectively, leading to poor performance.

- Clean Storage Needed: Storage tanks need regular cleaning to prevent contamination, which can compromise the quality of the emulsion.

Examples & Analogies

Think of a fresh salad. If not eaten quickly, it can spoil and go bad due to moisture. Similarly, bituminous emulsions need careful handling and can only be used within a specific time frame, proving that just like food, proper care considerably affects their usability.

Introduction to Bituminous Cutbacks

Chapter 11 of 18

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Bituminous cutbacks are prepared by dissolving bitumen in a volatile solvent (e.g., naphtha, kerosene) to reduce viscosity and enhance fluidity at ambient temperature. After application, the solvent evaporates, leaving behind a bituminous film.

Detailed Explanation

Bituminous cutbacks are made by mixing bitumen with a solvent that evaporates easily, like naphtha or kerosene. This mixing process reduces the thickness of the bitumen, making it easier to work with at normal temperatures. Once the cutback is applied to a surface, the solvent evaporates, leaving only the bitumen behind, which provides a protective coating or film. This application method is particularly useful when heating the bitumen isn't feasible.

Examples & Analogies

Imagine making soup. When you pour water into the thick base, it thins out and becomes easier to pour. Here, the solvent plays a similar role with bitumen, creating a 'soup' that can be applied easily and, once the water 'evaporates', leaves behind the tasty, thick bitumen layer.

Types of Bituminous Cutbacks

Chapter 12 of 18

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Classified based on curing time, which depends on the type of solvent used:

- Rapid Curing (RC):

- Uses highly volatile solvents like gasoline.

- Quick evaporation.

- Used for surface treatments like spray application.

- Medium Curing (MC):

- Uses moderately volatile solvents like kerosene.

- Intermediate rate of evaporation.

- Used for premix with coarse aggregates.

- Slow Curing (SC):

- Uses low volatility oils.

- Very slow evaporation.

- Suitable for prime coats or stabilization.

Detailed Explanation

Bituminous cutbacks can be categorized based on how quickly they cure or set, which is influenced by the solvent used:

1. Rapid Curing (RC): These cutbacks use very volatile solvents, allowing them to evaporate quickly when applied. This makes them suitable for surface treatments where fast drying is essential, like spray applications.

2. Medium Curing (MC): These cutbacks have a moderate evaporation rate thanks to the use of less volatile solvents. They are commonly used when mixing with coarse aggregates where some working time is needed before setting.

3. Slow Curing (SC): Using the least volatile solvents, these cutbacks have a very slow evaporation rate. They are ideal for applications like prime coats or stabilizing materials where longer setting time is advantageous.

Examples & Analogies

Choosing a type of cutback is like selecting different types of glue. Fast-drying glue (RC) is perfect for quick fixes, while a slow-drying adhesive might be better when you require time to position pieces. Understanding how quickly a cutback cures allows you to select the right one for your road construction needs.

Preparation of Bituminous Cutbacks

Chapter 13 of 18

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Bitumen is heated and mixed with the desired solvent in a controlled environment. Careful monitoring of temperature is necessary to prevent fire hazards. The resulting liquid is cooled and stored in sealed containers.

Detailed Explanation

The preparation of bituminous cutbacks involves a well-controlled process:

1. Heating: Bitumen is heated to make it easier to mix with the solvent. This must be done carefully to prevent overheating and fire hazards.

2. Mixing with Solvent: The heated bitumen is then combined with the chosen solvent. The ratio and method of mixing are crucial to ensure a consistent cutback product.

3. Cooling and Storage: After mixing, the cutback is allowed to cool and is stored in sealed containers to maintain its quality and prevent contamination.

Examples & Analogies

Imagine making a candle. You need to melt wax and combine it carefully with scents (like the solvent). If you heat too fast, it might catch fire. Once mixed and cooled, the wax needs to be poured into a mold (like storage) to set properly. Each step requires attention to detail to ensure the final product is safe and effective.

Characteristics of Bituminous Cutbacks

Chapter 14 of 18

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Lower initial viscosity compared to pure bitumen.

- Improved workability at lower temperatures.

- Setting time determined by solvent type.

- Penetration and ductility of the residue are key quality indicators.

Detailed Explanation

Bituminous cutbacks offer certain characteristics that make them easier to manage:

- They initially have lower viscosity than pure bitumen, meaning they can flow and be applied more easily.

- They maintain better workability even when the temperatures are lower, which is important for construction in cooler climates.

- The time it takes for the cutback to set can vary significantly depending on the type of solvent used, which aids in planning applications.

- Key quality indicators of cutbacks include the penetration (how easily a needle can enter the residue) and ductility (how much it can stretch before breaking) of the bitumen left behind after the solvent evaporates.

Examples & Analogies

Think about how cake batter is easy to spread compared to solid cake. Once baked, the cake takes time to set, much like how different solvents influence the setting time of cutbacks. Similarly, the ability to manipulate the mixture before it sets showcases the versatility and performance of cutbacks.

Tests on Bituminous Cutbacks

Chapter 15 of 18

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Distillation Test: Measures the percentage of volatile solvent. Helps determine cutback classification (RC, MC, SC).

- Penetration Test: Indicates consistency of residual bitumen.

- Ductility Test: Measures the ability of residue to stretch without breaking.

- Flash Point Test: Assesses safety and fire risk.

- Viscosity Test: Important for handling and application.

Detailed Explanation

Similar to emulsions, bituminous cutbacks also undergo a variety of tests to ensure quality and safety:

1. Distillation Test: This assesses how much of the mixture is made up of volatile solvents. Knowing the percentage helps classify whether a cutback is rapid, medium, or slow curing (RC, MC, SC).

2. Penetration Test: This test checks the consistency of the residual bitumen, ensuring it meets specific standards for application.

3. Ductility Test: This measures how much the bitumen residue can stretch before breaking, which is key to understanding its performance under stress.

4. Flash Point Test: This is crucial for safety as it assesses how flammable the product is and helps determine fire risk during storage and handling.

5. Viscosity Test: Just as with emulsions, this test evaluates how easily the cutback flows, which is critical for its application.

Examples & Analogies

If you were to take your car to a mechanic, they would run various tests to ensure everything is working well. Likewise, performing these tests on bituminous cutbacks ensures that they work igniting safety and efficacy standards, protecting public safety and ensuring quality work.

Uses of Bituminous Cutbacks

Chapter 16 of 18

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Tack and Prime Coats

- Premix for Cold Patch Work

- Dust Palliatives in Rural Roads

- Soil Stabilization

- Fog Seal Applications

Detailed Explanation

Bituminous cutbacks serve several important applications such as:

- Tack and Prime Coats: They are widely used to bond layers together in road construction, ensuring a strong connection.

- Premix for Cold Patch Work: Cutbacks can also be mixed with aggregates for cold patch repairs in potholes—allowing repairs without heating the materials.

- Dust Palliatives in Rural Roads: In unpaved areas, cutbacks help suppress dust, providing safer driving conditions, especially in dry regions.

- Soil Stabilization: They are also crucial in stabilizing loose soils, making them firmer and more robust for construction.

- Fog Seal Applications: This involves applying a light coating of cutback on existing pavements to rejuvenate and protect them.

Examples & Analogies

Using cutbacks is like having a multi-tool. Just as a multi-tool can serve various functions (like cutting, opening bottles, and screwing), bituminous cutbacks can adapt to different construction scenarios, making them versatile and effective in achieving a strong road infrastructure.

Comparison Between Bituminous Emulsions and Cutbacks

Chapter 17 of 18

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

| Parameter | Emulsions | Cutbacks |

|---|---|---|

| Base | Medium water | Volatile solvent |

| Environmental Impact | Environment-friendly | Harmful due to VOCs |

| Energy Requirement | Low | Moderate to high |

| Application | Can be used cold | Used cold |

| Temperature Storage Stability | Moderate | Good |

| Breaking Mechanism | Evaporation of water | Evaporation of solvent |

Detailed Explanation

Bituminous emulsions and cutbacks can be compared across several key parameters:

- Base: Emulsions are water-based while cutbacks use volatile solvents.

- Environmental Impact: Emulsions are generally safer for the environment, while cutbacks can release harmful volatile organic compounds (VOCs).

- Energy Requirement: Emulsions require low energy for application compared to cutbacks which can require moderate to high energy (due to heating).

- Application: Both can be used cold; however, cutbacks are more reliant on the evaporation of the solvent.

- Storage Stability: Emulsions have moderate storage stability while cutbacks generally last longer.

- Breaking Mechanism: Emulsions depend on water evaporation to dry, while cutbacks rely on solvent evaporation.

Examples & Analogies

Comparing emulsions to cutbacks is like comparing water-based paint to oil-based paint. The water-based paint (emulsions) is safer for the environment and easier to clean, while oil paint (cutbacks) may last longer but comes with its own set of challenges and releases toxins.

Environmental and Safety Considerations

Chapter 18 of 18

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Cutbacks release volatile organic compounds (VOCs) harmful to health and environment.

- Emulsions are safer and eco-friendly, with no risk of fire or explosion.

- Proper PPE must be worn during handling.

- Regulatory frameworks (e.g., CPCB guidelines in India) must be followed for storage and use.

Detailed Explanation

Both bituminous emulsions and cutbacks have specific environmental and safety considerations:

- Cutbacks can emit VOCs, which are harmful to both health and the environment, necessitating careful handling and proper safety measures.

- In contrast, emulsions are regarded as safer, posing much less risk of fire or explosions during application.

- Personal Protective Equipment (PPE) such as gloves and masks should be used when handling both materials to protect workers.

- Compliance with regulations, like the CPCB guidelines in India, is essential for their proper storage and usage to ensure safety and minimize environmental impact.

Examples & Analogies

Just like using chemicals at home, such as cleaning products that may have harmful fumes, it's important to follow safety instructions and use protection. In construction, using various emulsions and cutbacks requires clear methods and tools to minimize risks and ensure everyone is safe.

Key Concepts

-

Bituminous Emulsion: A stable suspension of bitumen in water, crucial for road construction.

-

Emulsifier: A key component that helps stabilize bituminous emulsions.

-

Types of Emulsions: Classified based on setting time and electrical charge for specific applications.

-

Bituminous Cutback: Involves bitumen combined with solvents to improve application properties.

-

Testing Procedures: Essential to ensure the quality and effectiveness of emulsions and cutbacks.

Examples & Applications

Using a Rapid Setting (RS) emulsion for surface dressing on a freshly paved road.

Mixing an MC cutback with coarse aggregates for patch repairs on existing roadways.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Emulsions have a mix, not too thick, bitumen, water, and a fixer!

Stories

Imagine a road builder who uses sticky glue (bitumen) and water in a big pot, adding a secret ingredient (emulsifier) to make it usable anytime, anywhere.

Memory Tools

Use WBEA—Water, Bitumen, Emulsifier, Additives to remember the components of emulsion.

Acronyms

Recall AL for Advantages and Limitations to simplify our conclusion discussion!

Flash Cards

Glossary

- Bituminous Emulsion

A mixture where bitumen droplets are suspended in water, stabilized by an emulsifier.

- Emulsifier

A surface-active agent that stabilizes an emulsion.

- Cationic Emulsion

An emulsion with a positive charge, suitable for negatively charged aggregates.

- Anionic Emulsion

An emulsion with a negative charge, best for basic aggregates.

- Bituminous Cutback

Bitumen dissolved in a volatile solvent to lower viscosity.

- Rapid Curing (RC)

Cutbacks with fast-evaporating solvents for quick applications.

- Medium Curing (MC)

Cutbacks with intermediate evaporating solvents for premixing.

- Slow Curing (SC)

Cutbacks with slow-evaporating solvents for stabilization.

Reference links

Supplementary resources to enhance your learning experience.