Characteristics of Bituminous Emulsions

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Viscosity

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Good morning class! Today, we're going to explore the viscosity of bituminous emulsions. Viscosity is a measure of a fluid's resistance to flow. Can anyone explain why viscosity is important for bituminous emulsions?

It's important because if the viscosity is too high, the emulsion won't spray correctly, right?

Exactly! The viscosity needs to be appropriate for either spraying or mixing. This affects the ease of application. Remember, we want it to ideally be 'just right'.

What happens if the viscosity is too low?

If it's too low, it may not adhere properly to the surface, leading to poor performance of the road. So we must balance viscosity carefully.

In short, we can think of viscosity as the 'stickiness' – it needs to be sufficient for effective application but not so high that it becomes difficult to work with.

Storage Stability

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, let’s discuss storage stability. Why do you think it's crucial for bituminous emulsions?

If they separate, then we can't use them properly, right?

Exactly! Storage stability ensures that emulsions resist separation into phases during storage. Unstable emulsions can lead to usability problems, which is why it’s a key characteristic.

What can cause instability in storage?

Factors like temperature fluctuations, incorrect emulsifier concentration, or impurities can all affect stability. Remember this: stable emulsions = reliable applications!

Residue Properties

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s delve into residue properties. What qualities do we want in the residual bitumen once the emulsion breaks?

Good adhesion would be important, I guess.

Correct! Good adhesion ensures the bitumen sticks well to the aggregate, which is vital for the road's durability. What else?

Ductility and penetration values?

Right! Ductility allows the residue to withstand deformation without cracking, while penetration indicates how well it can fill voids in the aggregate. All these attributes support the performance of the road.

Breaking Time

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Finally, we have breaking time. Can anyone explain what this means?

It's the time it takes for the emulsion to set on the aggregate after application?

Great! A faster breaking time is beneficial for surface treatments, while slower breaking times are advantageous for applications that require more mixing. Remember the dynamics: faster doesn't always mean better; it depends on the application!

So if I have a surface dressing application, I'd want a rapid setting emulsion?

Exactly! Each application requires careful selection of breaking time based on the project needs.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

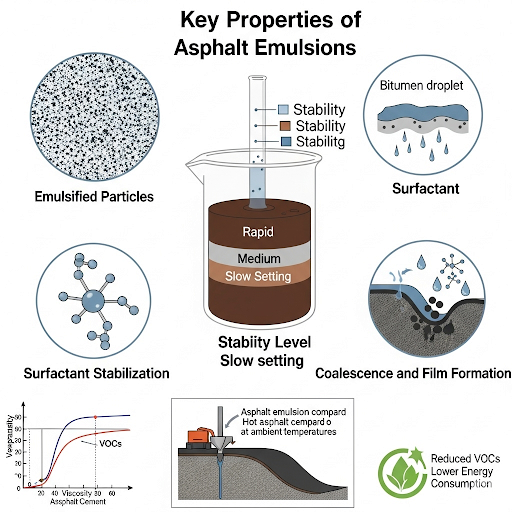

This section discusses the essential characteristics of bituminous emulsions necessary for their application in road construction. Key attributes include viscosity for application efficiency, storage stability for long-term use, desirable residue properties, and breaking time, which influences how quickly the emulsion sets after application.

Detailed

Characteristics of Bituminous Emulsions

The characteristics of bituminous emulsions are critical to their effectiveness in road construction applications. Key attributes include:

- Viscosity: This determines how readily the emulsion can be sprayed or mixed, impacting application efficiency.

- Storage Stability: Effective emulsions maintain separation resistance over time, ensuring usability and preventing phase separation.

- Residue Properties: After breaking, the residual bitumen must exhibit qualities such as good adhesion, ductility, and penetration to fulfill its role effectively in the road structure.

- Breaking Time: This indicates how quickly the emulsion breaks upon contact with aggregates, essential for determining suitability in different applications.

Understanding these characteristics helps in selecting the right emulsion type for specific construction tasks.

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Viscosity

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Viscosity: Should be appropriate for spraying or mixing.

Detailed Explanation

Viscosity is a measure of a fluid's resistance to flow. In the context of bituminous emulsions, the viscosity must be at an optimal level for effective spraying or mixing. If the viscosity is too high, the emulsion may not spread evenly or adhere properly to surfaces. Conversely, if it's too low, the emulsion may not perform well, potentially leading to inadequate bonding. Thus, it's crucial to control the viscosity during the emulsion formulation to ensure its practical application in road construction.

Examples & Analogies

Think of viscosity like honey and water. Honey is thick (high viscosity) and pours slowly, while water is thin (low viscosity) and pours quickly. If you're trying to cover a pancake with syrup, you want something that flows smoothly – too thick, and it clumps; too thin, and it runs off. Similarly, bituminous emulsions need to strike the right balance for effective application.

Storage Stability

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Storage Stability: Should resist separation of bitumen and water over time.

Detailed Explanation

Storage stability refers to the emulsion's ability to remain homogenous over time without the separation of its components. Bituminous emulsions are composed of bitumen, water, and emulsifiers; if they separate, the performance of the emulsion could be compromised. This characteristic ensures that when the emulsion is stored in tanks before use, it remains uniform and does not require re-mixing before application. Proper formulation and the use of suitable emulsifiers help achieve desirable storage stability.

Examples & Analogies

Imagine a salad dressing that separates into oil and vinegar if left too long. You need to shake it up before using it for the salad. In contrast, a well-made dressing stays mixed even after a long time on the shelf. Similarly, storage stability in bituminous emulsions is important to keep them ready for immediate use when needed.

Residue Properties

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Residue Properties: After breaking, the residual bitumen must have good adhesion, ductility, and penetration values.

Detailed Explanation

Once the emulsion is applied and breaks (the water evaporates), it leaves behind a layer of bitumen known as the residue. The properties of this residue are crucial for ensuring that the emulsion performs well in its intended application. Good adhesion means the bitumen will effectively bond to the aggregates, ductility refers to its ability to stretch without breaking, and penetration values indicate the hardness or softness of the residue. These factors significantly influence the longevity and durability of the road surface.

Examples & Analogies

Consider adhesive tape: if the residue (the sticky part) peels off easily, it won't stick well to surfaces. A residue with high ductility can be compared to a rubber band – it can stretch without breaking. Just like the tape needs to stick, bituminous residue must have the right properties to hold the road materials together effectively.

Breaking Time

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Breaking Time: Indicates how fast the emulsion breaks and sets on aggregate.

Detailed Explanation

Breaking time refers to the duration it takes for a bituminous emulsion to lose its water content and solidify on the aggregates. This property is crucial because it determines how quickly the emulsion can be effectively used during road construction. A shorter breaking time allows for faster application and quicker traffic resumption, while a longer time might delay the project. The time can vary based on the emulsion type used and the environmental conditions during application.

Examples & Analogies

Think of a sponge cake that needs to cool and set before you can cut it. If it cools too quickly, it may crack; if it takes too long, it might lose freshness. In road construction, emulsion breaking time works similarly – it needs to be optimal to ensure both immediacy and quality in road repairs.

Key Concepts

-

Viscosity: Important for application efficiency during spraying or mixing.

-

Storage Stability: Prevents phase separation in stored emulsions.

-

Residue Properties: Determines adhesion, ductility, and penetration after breaking.

-

Breaking Time: Crucial for setting speed upon contact with aggregates.

Examples & Applications

For a quick repair on a road surface, you would choose a rapid-setting emulsion due to its quick breaking time.

For soil stabilization, a slow-setting emulsion is preferred to allow mixing with fine aggregates.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

For viscosity that flows like air, make sure it's just right everywhere!

Stories

Imagine a painter with a thick and rich paint—if it's too sticky, it won’t spread, but too watery, it won't stick. Just like bituminous emulsions need balance!

Memory Tools

Remember RABB: Residue, Adhesion, Breaking, and Being stable to recall characteristics.

Acronyms

V-SR-B

Viscosity

Stability

Residue properties

Breaking time.

Flash Cards

Glossary

- Viscosity

A measure of a fluid's resistance to flow, indicating how easily it can be applied.

- Storage Stability

The ability of an emulsion to resist separation of its components over time.

- Residue Properties

Characteristics of the residual bitumen after the emulsion breaks, including adhesion, ductility, and penetration.

- Breaking Time

The time it takes for the emulsion to set upon contact with aggregates.

Reference links

Supplementary resources to enhance your learning experience.