Benefits of Fault Modeling and Simulation

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Early Fault Detection

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's start with early fault detection. Why do you think it is critical to identify potential faults before physical prototypes are built?

It probably saves money and time by fixing issues early!

Exactly! By diagnosing problems early, we can prevent the extensive costs associated with redesigning parts of the product. Let me put it this way: imagine building a house and realizing you forgot a major component after the walls are up. It would be much harder and more expensive to fix!

That makes a lot of sense! So, would you say this is a key reason why simulation is used?

Absolutely! Early fault detection is one of the main benefits of simulations. Can anyone remember the acronym for this benefit? It starts with an 'E'!

Is it ‘EFD’ for Early Fault Detection?

Great! EFD is essential in reducing project timelines. We’ll see how it overlaps with cost reduction next.

Cost Reduction

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let's talk about cost reduction. Can anyone explain how simulations contribute to reducing costs related to circuit designs?

Well, if we can test designs without needing to build physical prototypes, we save a lot of money!

Exactly! Each prototype iteration can be very expensive. Think of it as trying out outfits at a store before buying. Each outfit you try on costs money, but what if you could visualize them all in a virtual means first? That’s what simulation offers.

So, we essentially get more bang for our buck with simulations?

Yes! You could say that. Cost reduction through simulation is vital for companies, making them competitive. Let’s remember the acronym 'CR' for Cost Reduction going forward.

Comprehensive Fault Coverage

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, we’ll discuss comprehensive fault coverage. What do you think this means in the context of fault modeling and simulation?

I guess it means testing the design for as many types of faults as possible?

Right! Comprehensive fault coverage ensures that circuit designs withstand a wide range of possible faults. Think of it as preparing for a test—if you study only certain topics, you might fail on the unexpected questions. But if you cover all material, you'll be more prepared.

So, achieving high fault coverage is essential for reliability!

Exactly! Reliability is directly linked to comprehensive fault coverage. Make a note of 'CFC' for Comprehensive Fault Coverage.

Optimized Test Patterns

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Finally, let’s discuss optimized test patterns. How do you think simulations can help in creating better test patterns for circuit designs?

I think it helps identify which areas need more testing!

Correct! - By simulating faults and analyzing test coverage, engineers can refine test patterns to focus on weak points in the design—much like how good study habits might mean focusing on topics where you struggle.

So the result is less time spent on testing but better overall detection?

Yes! Optimized testing leads to not only increased efficiency but also an improved fault detection rate. Let’s summarize the key terms before we wrap up: EFD, CR, CFC, and OTP for Optimized Test Patterns.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

By leveraging fault modeling and simulation, engineers can detect potential faults early in the design process, significantly reducing costs associated with prototypes and extensive hardware testing. These methods ensure comprehensive fault coverage and allow for the optimization of test patterns, leading to improved reliability and efficiency in electronic systems.

Detailed

Detailed Summary

Fault modeling and simulation are pivotal in the engineering design process for electronic systems. They offer several significant benefits that directly impact the reliability, efficiency, and cost-effectiveness of product development. The key benefits include:

1. Early Fault Detection

Using fault models and simulation tools enables engineers to discover potential issues at the beginning of the design phase. This preventative measure helps to minimize costly rework and design revisions, ultimately shortening the product development cycle.

2. Cost Reduction

Simulation facilitates comprehensive testing and evaluation of circuit designs without the necessity of actual physical prototypes. This advantage leads to reduced costs associated with hardware testing and iterative prototype development.

3. Comprehensive Fault Coverage

Extended fault coverage analysis is possible with simulation tools. They enable engineers to test for a broad spectrum of potential faults, substantially improving the reliability and robustness of the design under various fault conditions.

4. Optimized Test Patterns

Through the simulation of faults and thorough analysis of test coverage, engineers can refine the test patterns utilized during production. This optimization enhances the efficiency and effectiveness of testing processes, resulting in decreased overall testing times and better fault detection rates.

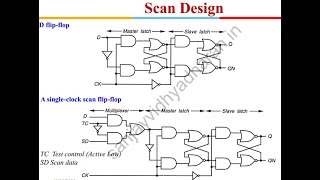

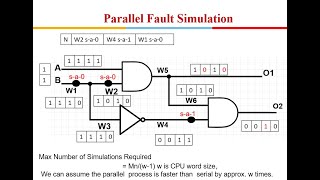

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Early Fault Detection

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

By using fault models and simulation tools early in the design process, engineers can identify potential issues before physical prototypes are built. This early detection helps prevent costly rework and design revisions, reducing development time and expenses.

Detailed Explanation

This chunk discusses how fault modeling and simulation can catch design issues at an early stage. Before building any physical prototypes—actual models of the design—engineers use simulations to test the circuit designs. If they detect problems, they can fix these issues in the design itself, which helps avoid expensive modifications later. This process not only saves money but also shortens the overall time it takes to complete the project.

Examples & Analogies

Think of this like a student drafting an essay. If they check their work for mistakes and make changes before submitting it, they won't have to redo the entire paper after getting feedback from their teacher. Just like revising an essay early keeps the project on track and avoids extra work, early detection in fault modeling helps engineers address issues before they become more complicated.

Cost Reduction

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Simulation allows designers to test and evaluate circuit designs without the need for extensive hardware testing. This reduces the cost associated with physical testing and prototype iterations, making the development process more cost-effective.

Detailed Explanation

Here, the emphasis is on cost savings achieved through simulation. Engineers can evaluate their designs using software without needing to create physical prototypes each time they want to test something. By reducing the amount of hardware testing required, companies save money on materials and manufacturing, making the overall design process more economical.

Examples & Analogies

Consider a chef testing a new recipe. Instead of making a whole batch of cookies—potentially wasting ingredients—they could first make a small sample. If it turns out well, they can then prepare the larger batch. Similarly, simulation lets engineers refine their designs efficiently without incurring the costs of extensive physical trials.

Comprehensive Fault Coverage

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Simulation tools allow for exhaustive fault coverage analysis, ensuring that the design has been tested for a wide range of potential faults. This enhances the reliability and robustness of the system, ensuring it can withstand various fault conditions.

Detailed Explanation

This chunk highlights the capability of simulation tools to perform thorough analyses on circuit designs. By using these tools, engineers can identify how different types of faults could impact the system and ensure that various failure scenarios have been considered. This preparedness leads to more reliable and robust designs, which are less likely to fail during real-world operation.

Examples & Analogies

Imagine a car safety test where various crash scenarios are simulated before the car goes into production. By thoroughly testing how the car performs during different accidents, engineers can ensure that it is safe for real-world use. Just like this, fault coverage analysis helps engineers prepare their circuit designs for potential failures.

Optimized Test Patterns

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

By simulating faults and analyzing test coverage, engineers can optimize the test patterns used in production. This leads to more efficient and effective testing, reducing the overall testing time and improving the fault detection rate.

Detailed Explanation

This chunk describes how engineers use simulation results to improve their testing strategies. After identifying possible faults, they can develop specific test patterns that are likely to uncover issues more efficiently. This optimization means that they spend less time on testing overall while still ensuring that they catch as many faults as possible.

Examples & Analogies

Think of it like studying for an exam. If you know certain topics are more likely to appear on the test, you would focus on those areas more intensely. Similarly, by understanding where faults are most likely to occur in a circuit, engineers can focus their testing efforts there, ensuring thoroughness without unnecessary extra work.

Key Concepts

-

Early Fault Detection (EFD): The critical ability to spot prospective faults in a design prior to creating physical prototypes.

-

Cost Reduction (CR): The significant decrease in expenses related to hardware testing and prototype iterations through simulation.

-

Comprehensive Fault Coverage (CFC): The evaluation measure that ensures various faults have been tested for, enhancing reliability.

-

Optimized Test Patterns (OTP): Enhanced directives for testing that target weaknesses and improve efficiency from simulation data.

Examples & Applications

Using simulation tools, a designer can identify faults in a circuit before testing it, thus saving time and testing costs.

By simulating fault conditions, engineers can optimize the test patterns used during production, ensuring better fault coverage.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

EFD finds faults, early and neat; saves our time, makes projects complete.

Stories

Imagine a baker who tests recipes by making samples in small batches first. This helps them avoid a failed cake at the big event—just like how simulations test circuits before full production!

Memory Tools

Cover every fault, EFD, CR, CFC, OTP!

Acronyms

Remember the acronym 'EC' for Early Cost savings when using Comprehensive techniques!

Flash Cards

Glossary

- Early Fault Detection (EFD)

The ability to identify potential issues in a design before physical prototypes are built.

- Cost Reduction (CR)

The decrease in costs associated with physical testing and prototype iterations due to the use of simulations.

- Comprehensive Fault Coverage (CFC)

The extent to which a design has been tested for various potential faults, ensuring robustness.

- Optimized Test Patterns (OTP)

Refined patterns used in testing to enhance efficiency and effectiveness based on simulation results.

Reference links

Supplementary resources to enhance your learning experience.