Utilization of Simulation Tools in Fault Detection

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Fault Simulation

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we'll explore fault simulation, a crucial part of utilizing simulation tools for detecting faults in electronic circuits. Can anyone explain what fault simulation is?

Isn't it about testing how faults affect the circuit design?

Exactly! Fault simulation applies fault models to see their impact. We mainly have two types: Boolean Fault Simulation and Timing Fault Simulation. Who can tell me the difference between these two?

I think Boolean Fault Simulation checks for stuck-at faults, while Timing Fault Simulation looks for delays in signal timing.

Correct! We look for conditions like stuck-at-1 or stuck-at-0 in Boolean simulations. For timing faults, we measure if the signals respect timing constraints. Let's remember: 'BS = Boolean Stuck'. Can you remember this?

Yeah! BS for stuck-at faults. That helps!

Great! Now let's wrap up this session: Fault simulation evaluates how faults affect circuits, distinguishing between Boolean and Timing types.

Diving into Functional Simulation

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, let's explore Functional Simulation. This type verifies logical correctness before testing hardware. Can anyone explain what makes a great functional simulation?

I guess it checks if the circuit produces the right outputs based on inputs?

Exactly! It ensures that the outputs match the expected results. Two important components here are testbenches and fault injection. Any insights on what a testbench includes?

It has input vectors and expected outputs to test the circuit.

Spot on! And what do you think fault injection achieves within this simulation?

It helps to see how the design responds to real faults.

Exactly! Functional simulations are vital for assessing fault tolerance. Remember, 'F for Functionality' in the examination. Can we recap some key insights here?

Functional simulation verifies correctness, using tools like testbenches and incorporating fault injection!

Exploring Circuit-Level Simulation

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s delve into Circuit-Level Simulation. This examines individual component behavior. How can we leverage this for fault detection?

It allows us to see how faults like open circuits affect the whole design.

Exactly! Tools like SPICE help simulate analog and mixed-signal circuits. What do we know about Monte Carlo simulation?

That it's used for analyzing values and determining how variations affect performance.

Correct! It's great for identifying subtle fault conditions. Let’s remember, 'C for Components'—it's all about understanding the pieces that make up the circuit. Quick recap?

Circuit-Level Simulation focuses on individual components, highlighting how faults impact overall design!

Understanding Fault Coverage Analysis

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let's review Fault Coverage Analysis. Why is it crucial after running simulations?

To see how many faults our tests can actually detect?

Yes! We measure fault coverage as a percentage. Common tools like Synopsys DFT Compiler help us identify gaps in coverage. Why is high fault coverage important?

It means our tests are more comprehensive, catching more potential failures!

Exactly! A higher coverage equates to a more reliable design. Remember, 'C for Coverage' symbolizes the goal of maximizing fault detection efficiency. Can anyone summarize this main point?

Fault coverage analysis helps us assess our test vectors' effectiveness and improve reliability.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section discusses how simulation tools facilitate fault detection through fault simulation, functional simulation, and circuit-level simulation, enhancing the reliability and robustness of electronic systems by identifying faults efficiently.

Detailed

Utilization of Simulation Tools in Fault Detection

Simulation tools are indispensable in the field of fault detection, providing engineers with the ability to evaluate circuit performance under various fault conditions without the need for physical prototypes. This section outlines several key types of simulation tools employed in fault detection:

7.3.1 Fault Simulation

- This involves the application of fault models to circuit designs. We can categorize fault simulation into two types:

- Boolean Fault Simulation: Primarily checks for stuck-at faults in logic circuits, determining if faults can be detected using provided test vectors.

- Timing Fault Simulation: Aims at detecting delay faults by monitoring the timing of signal propagation through the circuit, identifying any timing violations.

7.3.2 Functional Simulation

- This simulation verifies the logical correctness of the circuit, ensuring it produces correct outputs for given inputs. Key components include:

- Testbenches: These are sets of input vectors and expected outputs that help evaluate circuit functionality.

- Fault Injection: Techniques to simulate faults within the design, allowing engineers to assess the system’s fault tolerance effectively.

7.3.3 Circuit-Level Simulation

- Focused on individual components and their interactions, particularly useful for analog circuits. Notable types of simulations include:

- SPICE Simulation: A tool that simulates circuit behavior, enabling assessment of faults like open circuits or component variations.

- Monte Carlo Simulation: A statistical approach for analyzing the impact of uncertainties in component values on circuit performance.

7.3.4 Fault Coverage Analysis

- After simulations, engineers measure the effectiveness of their test vectors through fault coverage metrics, which indicate the percentage of detectable faults by the test patterns. Numerous simulation tools, such as Synopsys DFT Compiler and Mentor Graphics Tessent, facilitate this analysis, supporting the optimization of test vectors to enhance fault detection capabilities.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Importance of Simulation Tools

Chapter 1 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Simulation tools play a crucial role in analyzing how fault models affect the performance of a system. They allow engineers to simulate and test the behavior of circuits under various fault conditions without physically fabricating the design, saving both time and costs.

Detailed Explanation

Simulation tools are essential for evaluating how faults would impact an electronic system's functionality. Rather than producing hardware, engineers can use these tools to model and test the design digitally. This approach dramatically reduces both time and expense, enabling quicker iterations and refinements without the need to physically build prototypes.

Examples & Analogies

Think of simulation tools like flight simulators used by pilots. Just as flight simulators allow pilots to practice and manage various emergency scenarios without the risks associated with real flights, simulation tools enable engineers to explore potential faults in circuit designs safely and effectively.

Fault Simulation

Chapter 2 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

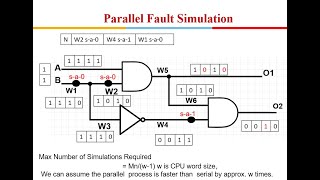

Fault simulation involves applying fault models to a circuit design and running simulations to observe how the faults impact the system’s behavior. There are two primary types of fault simulation:

- Boolean Fault Simulation: This type of simulation applies the stuck-at fault model to logic circuits. It checks whether a fault, such as a stuck-at-1 or stuck-at-0 condition, is detectable with the given test vectors.

- Timing Fault Simulation: This type of simulation is used to detect delay faults by simulating the timing of signals as they propagate through the circuit. Timing fault simulation tools can detect whether signals meet timing constraints and identify any violations.

Detailed Explanation

Fault simulation is the process by which engineers examine how specific faults, predicted by fault models, could affect circuit performance. There are two key types: Boolean Fault Simulation checks logical faults like a component stuck at a high or low setting, while Timing Fault Simulation assesses whether signals correctly transition through the circuit over time. Both types of simulation help engineers determine if their testing strategies can effectively identify these faults.

Examples & Analogies

Imagine diagnosing a car that won't start. A mechanic could simulate various electrical faults (like a dead battery or faulty starter) to see which condition prevents the car from functioning. Similarly, fault simulation allows engineers to identify which faults might cause a circuit to fail.

Functional Simulation

Chapter 3 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Functional simulation is used to verify the logical correctness of a circuit before physical testing. It checks whether the system produces the correct outputs for the given inputs, often using testbenches that simulate various operating conditions.

- Testbenches: A testbench is a set of input vectors, expected outputs, and clock cycles used to test the functionality of a circuit. It ensures that the circuit functions correctly under normal conditions and helps detect potential design errors.

- Fault Injection: In functional simulation, fault injection can be used to simulate faults in the design and observe how the system responds. This allows engineers to assess the fault tolerance of the design and ensure it can handle real-world faults effectively.

Detailed Explanation

Functional simulation checks if a circuit design operates correctly by testing various inputs and comparing the outputs against expected results. Testbenches help organize these tests, while fault injection allows engineers to introduce faults into the design to see how the system reacts. This is crucial for ensuring that the design is robust enough to manage unexpected conditions in real-world applications.

Examples & Analogies

Think of functional simulation like a dress rehearsal for a play. Just as actors practice their lines and blocking to ensure the performance runs smoothly, engineers use functional simulation to ensure that their circuits will function as expected under different conditions, catching potential errors before the 'show' goes live, which is the actual production run.

Circuit-Level Simulation

Chapter 4 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Circuit-level simulation involves simulating the behavior of individual components and their interactions. This type of simulation is particularly useful for detecting faults in analog circuits and for identifying problems in power distribution or signal integrity.

- SPICE Simulation: SPICE (Simulation Program with Integrated Circuit Emphasis) is a popular tool used for circuit-level simulation of analog and mixed-signal circuits. SPICE models the behavior of resistors, capacitors, transistors, and other components, allowing engineers to simulate how faults like open circuits or component value changes affect circuit performance.

- Monte Carlo Simulation: Monte Carlo simulation is a statistical method used to analyze the impact of uncertainties in component values (such as resistors or capacitors) and how they affect the overall circuit performance. This simulation is useful for identifying rare or hard-to-detect faults that might arise from component variations or manufacturing tolerances.

Detailed Explanation

Circuit-level simulation allows for detailed analysis of how each component behaves and interacts within a circuit. Tools like SPICE facilitate this by creating virtual versions of components to see how they would react under certain fault conditions. Monte Carlo simulation further adds depth by accounting for variability among components, helping engineers understand rare fault scenarios that might not be immediately obvious.

Examples & Analogies

Think of circuit-level simulation like a woodworking project where you test various types of wood to see which one withstands certain conditions best. Just as you would evaluate how each type of wood responds to moisture or pressure, engineers analyze different components in a circuit to understand how faults affect overall performance.

Fault Coverage Analysis

Chapter 5 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

After running fault simulations, engineers must assess the effectiveness of their test vectors by measuring fault coverage, which is the percentage of faults detected by the test patterns. Higher fault coverage indicates a more comprehensive test suite. Simulation tools often provide coverage metrics to help engineers evaluate whether additional test vectors are needed to detect undetected faults.

- Fault Simulation Tools: Tools like Synopsys DFT Compiler, Mentor Graphics Tessent, and Cadence Modus are commonly used for fault simulation and coverage analysis. These tools integrate with circuit designs to perform fault injection and report coverage statistics.

Detailed Explanation

Fault coverage analysis is an essential step in validating the strength of testing strategies. By measuring how many faults are detected by the test patterns, engineers can identify areas needing improvement. High fault coverage means more robustness in the circuit design. Tools like Synopsys DFT Compiler help automate this analysis, providing valuable feedback on test efficacy.

Examples & Analogies

Imagine a safety inspection of a building where inspectors evaluate if all potential issues (like fire hazards, structural weaknesses) have been identified and addressed. Similarly, fault coverage analysis ensures that all possible faults in a circuit have been tested and either fixed or accounted for.

Key Concepts

-

Fault Simulation: A technique to analyze how faults affect circuit behavior.

-

Boolean Fault Simulation: Focuses on detecting stuck-at faults.

-

Timing Fault Simulation: Examines timing-related issues in signal propagation.

-

Functional Simulation: Verifies logical correctness of circuits.

-

Testbench: Comprises input/output vectors for evaluating functionality.

-

Circuit-Level Simulation: Studies interactions of individual components in circuits.

-

SPICE: A widely-used tool for simulating electronic circuits.

-

Monte Carlo Simulation: A method for analyzing performance under uncertainty.

-

Fault Coverage: The extent of fault detection achieved through testing.

Examples & Applications

A stuck-at-1 fault occurs in a circuit when a signal permanently remains high, affecting logic outputs.

In functional simulation, if a circuit is tested with inputs that result in incorrect outputs, it indicates a design flaw that needs addressing.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

For circuits that we design, faults we always must find, through simulation we explore, to make our systems even more!

Stories

Imagine a detective using tools like a magnifying glass (like SPICE) to uncover hidden problems in a complex city (the circuit), ensuring everything runs smoothly and reliably.

Memory Tools

F-B-T-C, meaning Fault simulation, Boolean and Timing methods, and Circuit-Level analysis!

Acronyms

F-Functional, T-Timing, C-Circuit

Used to remember the types of simulations for our designs.

Flash Cards

Glossary

- Fault Simulation

A method of testing a circuit design by applying fault models to understand their impact on system performance.

- Boolean Fault Simulation

A simulation focusing on detecting stuck-at faults in logic circuits.

- Timing Fault Simulation

Simulation used to identify timing violations in signal propagation within a circuit.

- Functional Simulation

A verification method that checks the logical correctness of a circuit by comparing outputs against expected results.

- Testbench

A set of defined input vectors and expected outputs used to evaluate a circuit’s functionality.

- Fault Injection

The process of simulating faults within a design to test the system's response and fault tolerance.

- CircuitLevel Simulation

Simulation that focuses on the behavior and interaction of individual components within a circuit.

- SPICE

A tool used for simulating analog and mixed-signal circuits.

- Monte Carlo Simulation

A statistical method used to analyze the impact of component value variations on circuit performance.

- Fault Coverage

The percentage of detectable faults in a circuit tested with given test vectors.

Reference links

Supplementary resources to enhance your learning experience.