Fault Modeling and Simulation

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Fault Modeling

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Good morning, class! Today we'll start by discussing fault modeling. Can someone tell me what fault modeling is?

Is it about understanding how faults can happen in circuits?

Exactly! Fault modeling involves defining the types of faults that might happen in an electronic system before manufacturing. Why do you think this is important?

It helps ensure the circuit works correctly and saves time and money if something goes wrong later!

Correct! By predicting faults early, engineers can optimize test coverage and enhance system reliability. Let’s remember this with the acronym 'AIM'—‘Analyze, Identify, Mitigate’.

What does 'Mitigate' mean in this context?

Good question! It means to reduce or control the impact of faults. Our goal is to ensure that systems are resilient. Let's move on to discussing specific fault models.

Types of Fault Models

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let's dive into some specific types of fault models, starting with the Stuck-At Fault Model. Can anyone provide a brief explanation?

Is that when a wire or signal stays at the same value regardless of the input?

Correct, Student_4! For example, if a signal is stuck at a '1', the circuit won't behave as intended. What's another fault model we might use?

There's the Transition Fault Model, which happens when signals don’t change states as expected.

Exactly! Transition faults are critical for catching timing issues. Let's remember 'STA' for Stuck-At and 'TF' for Transition Faults. Can anyone tell me how these faults can affect a circuit’s operation?

They can cause outputs to be incorrect, which could lead to system failures.

Well done! Understanding these models is essential for designing reliable circuits.

Simulation Tools for Fault Detection

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Moving on, let’s talk about simulation tools in detecting faults. Who can explain what fault simulation involves?

It applies the fault models to a circuit design to see how they impact performance, right?

Exactly! We have Boolean Fault Simulation and Timing Fault Simulation. Can someone differentiate between the two?

Boolean checks logic states, while Timing checks if signals meet timing constraints.

Perfect! Proper use of these simulations allows for effective fault analysis without physical prototypes. Let's remember 'BFT' for Boolean Fault Testing and 'TF' for Timing Faults.

What happens if we have high computational costs running these simulations?

Great question! High costs can slow down the design process, highlighting the importance of efficient simulation techniques and models.

Benefits of Fault Modeling

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

What are some benefits we can achieve using fault modeling and simulation?

We can catch faults early and save money on manufacturing!

Absolutely! Early fault detection helps prevent costly revisions. Another benefit is optimizing test patterns. What does that involve?

It means making our tests more effective at finding faults!

Well done! Let’s use 'FLEET' to remember: Fault detection, Lower costs, Efficient testing, Early revisions, and Test optimization. Any questions?

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section discusses the significance of fault modeling and simulation in modern electronic design, detailing various types of fault models used for both digital and analog circuits. It explores how these models aid in early fault detection, cost reduction, and optimizing test coverage, along with the limitations of fault modeling and simulation.

Detailed

Fault Modeling and Simulation

Fault modeling and simulation play crucial roles in the design of electronic circuits by allowing engineers to predict potential issues before the manufacturing phase. With the increasing complexity of integrated circuits (ICs) and systems-on-chip (SoCs), identifying and mitigating faults has become more challenging. This section dives into:

Introduction to Fault Modeling and Simulation

Fault modeling helps define what types of faults can occur in a system, while simulation tools allow evaluation of the system’s performance under different fault conditions. This process identifies weak points in designs, optimizes test coverage, and improves overall reliability.

Development of Fault Models for Electronic Circuits

Fault models are simplified representations of potential real-world failures. Common models include:

1. Stuck-At Fault Model (SAF): Represents conditions where a signal is stuck at either a logic high or low.

2. Transition Fault Model (TF): Indicates failures where signals fail to change states as expected.

3. Delay Fault Model (DF): Addresses timing issues where signal propagation delays lead to operational errors.

4. Bridging Fault Model (BF): Occurs when unintended connections between signal lines affect circuit behavior.

5. Open Circuit Fault Model: Occurs when a connection in a circuit is broken, leading to disconnections and possible system failures.

Analog circuits utilize different fault models such as gain faults, offset faults, and component value faults due to their continuous nature.

Utilization of Simulation Tools in Fault Detection

Simulation tools are key in assessing how fault models impact system performance, including:

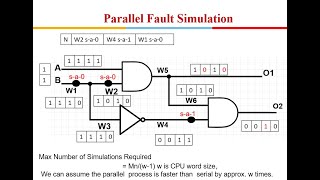

- Fault Simulation: Two types exist—Boolean fault simulation focuses on detecting identifiable logic faults, and timing fault simulation identifies timing-related issues.

- Functional Simulation: Verifies the logical correctness of a circuit through comprehensive testing.

- Circuit-Level Simulation: Assesses individual component behavior and interactions using tools like SPICE and Monte Carlo methods for analyzing uncertainties.

- Fault Coverage Analysis: Evaluates test pattern effectiveness by measuring the percentage of faults detected.

Benefits of Fault Modeling and Simulation

The advantages include:

- Early fault detection, reducing development costs and time.

- Comprehensive fault coverage assessments, increasing design reliability.

- Optimization of testing efficiency and fault diagnosis.

Limitations of Fault Modeling and Simulation

Despite their benefits, limitations include inadequate coverage for complex fault scenarios, high computational demands for simulations, and reliance on accurate models to avoid false conclusions.

In conclusion, fault modeling and simulation remain vital to electronic system development, enabling reliable and robust circuit designs.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Introduction to Fault Modeling and Simulation

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

In modern electronic design, fault modeling and simulation are vital tools used to predict and analyze potential faults in a system before manufacturing. As integrated circuits (ICs) and systems-on-chip (SoCs) grow in complexity, ensuring reliability through comprehensive fault detection becomes more challenging. Fault modeling involves defining specific types of faults that could occur in a system, while simulation tools allow engineers to apply these fault models to evaluate the behavior of the system under different fault conditions. Fault modeling and simulation help identify weak points in a design, optimize test coverage, and enhance system reliability. In this chapter, we will explore the development of fault models, the different types of faults, and how simulation tools are used to predict and analyze faults in electronic circuits.

Detailed Explanation

This introductory section explains the importance of fault modeling and simulation in electronic design. As technology evolves, the complexity of circuits increases, making it harder to ensure they work reliably. Fault modeling helps designers understand what types of faults might occur, while simulation lets them test how these faults would affect circuit behavior without building physical prototypes. This process is crucial for identifying potential weaknesses in designs and improving test procedures to ensure circuits remain reliable. The chapter will cover different fault models and their applications in simulation.

Examples & Analogies

Think of a car manufacturing process. Before building a car, engineers use simulations to test for potential issues like engine failures or braking problems based on different driving conditions. Just like this, engineers in electronics use simulations to catch problems in circuit designs before the actual product is made.

Development of Fault Models for Electronic Circuits

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

A fault model represents a simplified abstraction of real-world failures that might occur in an electronic system. Fault models are essential for ensuring that a system can be effectively tested under realistic conditions. Fault models help define what kind of faults the system should be able to detect, and guide the development of test strategies and patterns for efficient verification.

Detailed Explanation

Fault models serve as simplified versions of possible failure scenarios that could occur in an electronic system. They are critical in designing tests that can adequately verify a circuit's functionality. By defining specific faults that the system should have mechanisms to detect, engineers can create effective test patterns and strategies to ensure that the system behaves correctly under different conditions.

Examples & Analogies

Imagine a fire alarm system. The designers create models for various types of alarms based on different kinds of fires it might face, such as smoke or heat detection. By simulating these scenarios, they can ensure the alarm works efficiently. Similarly, engineers develop fault models to simulate how circuits can fail to verify they can handle different electrical issues.

Types of Fault Models

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The following are some of the most widely used fault models in digital circuit testing:

- Stuck-At Fault Model (SAF): The stuck-at fault is the most commonly used fault model in digital circuits. It assumes that a logic gate or signal line is stuck at a logic high (1) or a logic low (0) regardless of the input.

- Transition Fault Model (TF): A transition fault occurs when a signal does not change from one logic state to another as expected. These faults are important for detecting timing problems, such as incorrect signal propagation or delays in logic transitions.

- Delay Fault Model (DF): Delay faults refer to the situation where the propagation delay in a signal is longer than expected, causing the system to miss the correct timing window for a logic operation.

- Bridging Fault Model (BF): A bridging fault occurs when two or more signal lines are unintentionally connected, often due to a short circuit between them.

- Open Circuit Fault Model: An open circuit fault occurs when a connection in the circuit is broken, leading to a disconnected node or floating signal.

Detailed Explanation

This section describes several types of fault models commonly used in testing digital circuits. The Stuck-At Fault Model (SAF) pinpoints situations where a signal remains high or low, leading to predictable failures. Transition Fault Models (TF) track the expected changes in logic states to catch delays in signal processing. Delay Fault Models (DF) focus on timing issues where signals take too long to propagate, which could disrupt operations. Bridging Fault Models (BF) deal with accidental connections between lines, while Open Circuit Fault Models identify broken connections. Each model aids engineers in focusing on specific fault types during testing.

Examples & Analogies

Consider traffic lights on a road where each light turning green or red signifies a change in traffic flow. If a light gets stuck on green (stuck-at fault), traffic builds up inconsistently. If a signal doesn’t transition as it should (transition fault), cars may start moving at the wrong time. Just like ensuring a traffic system functions well, engineers use these fault models to ensure circuits operate correctly under various failure scenarios.

Key Concepts

-

Fault Modeling: Defining potential faults to improve system reliability.

-

Stuck-At Fault Model: A model where a signal stays at a constant value regardless of input.

-

Transition Fault Model: A model that detects failures in signal state transitions.

-

Delay Fault Model: Evaluating timing issues in signal propagation.

-

Simulation Tools: Critical for predicting and analyzing faults in circuits.

Examples & Applications

An example of a Stuck-At fault is when a particular gate in a circuit constantly reports high, irrespective of its input signals.

A Delay Fault occurs when a signal takes longer to propagate than expected, possibly leading to timing violations in high-speed circuits.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

For modeling faults, don’t fret or stall, just remember SAF, TF, they cover it all!

Stories

Imagine trying to cross a bridge with a stuck sign; you'd go nowhere, just like a stuck-at fault traps signals in design.

Memory Tools

Remember 'BFT'—Boolean Fault Testing for logical faults!

Acronyms

'FLEET' – Fault detection, Lower costs, Efficient testing, Early revisions, Test optimization.

Flash Cards

Glossary

- Fault Modeling

A process of defining potential faults in a system to analyze how they may affect performance.

- StuckAt Fault

A condition where a signal remains permanently high or low regardless of input.

- Transition Fault

A fault where a signal fails to change from one state to another as expected.

- Delay Fault

A scenario where signal propagation delays exceed acceptable timing limits.

- Bridging Fault

An unintended connection between two signal lines that disrupts circuit functionality.

- Open Circuit Fault

A fault condition where a circuit connection is broken, leading to disconnected nodes.

- Fault Simulation

The use of simulation tools to evaluate the effect of faults on circuit behavior.

- Functional Simulation

Simulation to verify the logical correctness of a circuit prior to physical testing.

- CircuitLevel Simulation

Simulation focusing on individual component behavior and interactions within a circuit.

- Fault Coverage

A metric indicating the percentage of detected faults by a given set of test patterns.

Reference links

Supplementary resources to enhance your learning experience.