Limitations of Fault Modeling and Simulation

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Overview of Limitations

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're discussing the limitations of fault modeling and simulation. First, can anyone tell me why these limitations matter?

It’s important because if we overlook the limitations, we might miss crucial faults in complex systems!

Exactly! Knowing the limitations helps us ensure thorough testing. Let’s start with limited coverage for complex faults. What do we mean by that?

That simulation tools might not cover every possible fault, especially in complicated systems?

Right! Complex systems can exhibit unexpected faults that a basic simulation might overlook. Therefore, we need additional testing methods. Now, why else might simulations not detect every fault?

Maybe due to the high computational cost, we can't run as many simulations as we'd like?

Great point! Computational costs can limit our ability to simulate all scenarios. We have to optimize our simulations. Finally, let’s address the dependency on accurate models. Why is that crucial?

If the models are inaccurate, we could get false positives or miss faults entirely!

Exactly! Inaccurate models compromise the reliability of our simulations. So, in summary, understanding these limitations is vital for effective fault detection. Any questions?

Computational Costs

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s delve deeper into the high computational cost of running simulations. What are some ways we can manage these costs?

We could prioritize the simulations that are most likely to reveal significant faults.

Yes, risk-based approaches help focus efforts wisely. What else might we consider?

Running simulations in parallel could save time, right?

Absolutely! Parallel processing allows for faster results, though it often requires more resources. Finally, how does optimizing simulations help?

It might allow us to run more detailed simulations without spending too much time or resources.

Great observation! Optimization ensures maximum efficiency. Let’s summarize: managing costs and resources in simulations is critical for effective fault modeling.

Accurate Models

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let's focus on the dependency on accurate models. Why is accuracy crucial in fault modeling?

If we use inaccurate models, we won’t detect real faults, and that can lead to failures in actual products.

Spot on! How can we ensure we develop and maintain accurate fault models?

Regularly updating them based on new fault data might help.

Exactly! Continuous improvement in model accuracy is key to reliability. Any final thoughts on how these limitations shape our fault detection strategy?

We need to combine multiple approaches to ensure better coverage and accuracy.

Great conclusion! Using a mix of tools maximizes our fault detection potential.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

In this section, we examine the constraints of fault modeling and simulation in electronic design. Key limitations include limited coverage for complex faults, high computational costs for simulations, and a reliance on the accuracy of the fault models utilized, which can affect the effectiveness of fault detection.

Detailed

Limitations of Fault Modeling and Simulation

While fault modeling and simulation are essential tools for predicting and analyzing faults in electronic systems, they come with several limitations that can impact their effectiveness:

1. Limited Coverage for Complex Faults

Simulation tools may not consider every possible fault, particularly in complex systems with atypical failure modes. As complexity increases, the probability of unforeseen faults also rises, necessitating complementary testing methods for thorough fault detection.

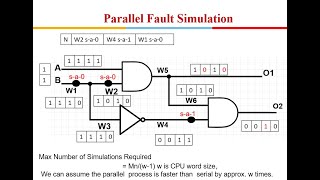

2. High Computational Cost

Running simulations, especially on large systems, can be computationally expensive and time-consuming. Engineers frequently need to optimize their simulation processes or run them in parallel to manage these costs effectively.

3. Dependency on Accurate Models

The success of fault detection relies heavily on the accuracy of the fault models used in simulations. If a model is inaccurate or incomplete, it may result in either false positives or undetected faults, ultimately undermining the reliability of the system being tested. This underscores the importance of continually improving fault models to ensure they reflect reality adequately.

Understanding these limitations is crucial for engineers to effectively plan for fault detection strategies and employ additional testing methodologies where necessary, ensuring robust and reliable electronic systems.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Limited Coverage for Complex Faults

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Simulation tools may not always account for every possible fault, especially in highly complex systems or those with non-typical failure modes. It’s important to complement simulation with other testing methods to ensure comprehensive fault detection.

Detailed Explanation

This chunk explains that simulation tools, while useful, have limitations in that they may not identify every potential fault in a complex system. This happens particularly in systems that may have failures not typically accounted for in the simulation. Therefore, engineers should use a combination of simulation and additional testing methods to ensure that all possible faults are detected and addressed. It's crucial to recognize that relying solely on simulations can lead to oversights.

Examples & Analogies

Imagine a fire alarm system in a large building. The simulation of different fault scenarios might predict common failures like a disconnected wire. However, it might miss rare issues like a malfunctioning smoke detector that only activates under specific conditions. Just like you wouldn't rely entirely on simulations for a fire alarm test, engineers shouldn't depend solely on fault simulations.

High Computational Cost

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Running simulations, especially on large systems, can be computationally expensive and time-consuming. In some cases, simulations may need to be optimized or run in parallel to reduce processing time.

Detailed Explanation

This chunk addresses the computational challenges associated with running simulations for fault modeling. As systems grow larger and more complex, the simulations become increasingly resource-intensive. This can result in high costs in terms of computational power and time required to complete the simulations. To mitigate these challenges, engineers often need to optimize their simulation processes or use parallel processing techniques to speed up the simulations. Understanding this limitation is essential in managing design timelines.

Examples & Analogies

Consider trying to cook multiple dishes for a large family dinner at once. If you only have one stove, it can take forever, and you might end up rushing or burning something. On the other hand, if you use a bigger kitchen or multiple stoves, you can cook everything more efficiently. Just like you’d need to optimize your cooking methods for a big dinner, engineers have to optimize simulations to handle large system designs efficiently.

Dependency on Accurate Models

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The effectiveness of fault simulation depends on the accuracy of the fault models used. Inaccurate or incomplete models may lead to false positives or missed faults, which could impact the reliability of the system.

Detailed Explanation

This chunk focuses on the critical importance of using accurate fault models in simulations. The success of fault modeling depends significantly on how representative these models are of real-world conditions. If the models are not precise—either due to errors in their design or because they don’t fully capture the types of faults that could occur—engineers risk either detecting faults that aren’t there (false positives) or missing serious faults altogether. This can greatly affect the overall reliability of the electronic system being developed.

Examples & Analogies

Think about a safety inspection for a car. If the inspection criteria are based on outdated or incorrect information about the car's safety features, it might miss significant issues, like a faulty brake system. This can lead to serious accidents. Similarly, if fault models are inaccurate, the simulation won't provide a true assessment of the system's reliability, potentially leading to failures in the actual product.

Key Concepts

-

Limited Coverage: Fault modeling may not capture every potential fault, especially in complex circuits.

-

High Computational Cost: Running simulations can be resource-intensive, requiring optimization strategies.

-

Dependency on Model Accuracy: Fault simulation efficacy is heavily reliant on the accuracy of the models used.

Examples & Applications

For example, in a complex digital circuit, a transition fault can occur due to unexpected delays, which may not be simulated accurately.

If a stuck-at fault is modeled incorrectly, it could lead engineers to believe a component is functioning correctly when it is not.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Faults can be dense, we run a test, / Costly and long, must find the best.

Stories

Imagine a detective trying to solve a complex case. Without the right clues (accurate models), they may miss crucial evidence (faults).

Memory Tools

C.A.M. for remembering limitations: Coverage, Accuracy, Cost Management.

Acronyms

L.C.A. - Limitations

Limited Coverage

Costs High

Accuracy Dependency.

Flash Cards

Glossary

- Fault Modeling

The process of defining specific types of faults that can occur in a system to facilitate testing and analysis.

- Simulation

The use of models to replicate the behavior of a system under certain conditions, particularly for testing fault conditions.

- Fault Detection

The process of identifying faults in a system using various methods, including modeling and simulation.

- Computational Cost

The resources required, such as time and processing power, to perform simulations or analyses.

- Model Accuracy

The degree to which a fault model accurately represents real-world faults in a system.

Reference links

Supplementary resources to enhance your learning experience.