Early Fault Detection

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Early Fault Detection

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we’ll be discussing early fault detection. Can anyone tell me why catching faults early in design is crucial?

I think it's important to avoid problems later when we have a prototype.

Exactly! Early detection helps prevent costly rework after a prototype is built. Can someone explain what we mean by ‘fault models’?

Fault models are the different types of potential failures we expect in a design, right?

Yes! They define how we can detect faults and guide our testing strategies. Now, what are some benefits of detecting faults early?

We save time and money, plus we can improve the design's reliability.

Great points! Remember, early fault detection optimizes the entire design process.

Tools for Early Fault Detection

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

What types of simulation tools can help with early fault detection?

I believe we can use tools that simulate fault conditions before physical testing.

Correct! Simulation tools allow us to apply fault models to designs, which helps us predict how the circuits might behave under fault conditions. Can anyone summarize how this reduces costs?

By catching problems before hardware is made, we avoid expensive prototypes.

Exactly! This proactive approach is key to efficient development and testing.

Case Study of Early Fault Detection

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s look at a case study where early fault detection made a significant impact. Who can suggest how an engineer might approach this?

They should start with defining their fault models and then use simulation tools to apply these to the design.

Great suggestion! This way, the engineer identifies weak spots before any significant costs accrue. Why do you think this practice is essential in industries with stringent reliability requirements?

Because failures could lead to serious safety issues or financial losses.

Exactly! Reliability is critical, and early fault detection contributes significantly to achieving it.

Summary of Key Learnings

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

As we wrap up, can anyone summarize the key benefits of early fault detection we discussed today?

It helps save time and money and improves reliability before prototypes are built.

Excellent summary! Remember to always consider how early fault detection integrates into the overall design process in electronics.

I've learned that using simulation tools is crucial for identifying faults early.

Perfect! Always remember the impact of early detection—it’s a game-changer in electronics design.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section discusses the importance of early fault detection in electronic design, highlighting how fault models and simulation tools can identify potential issues early, saving time and costs associated with rework and prototype development. It emphasizes the necessity of comprehensive testing strategies during the design process.

Detailed

Early Fault Detection

Early fault detection is a critical practice in modern electronic design that leverages fault models and simulation tools to uncover potential issues in circuit designs before physical prototypes are generated. This proactive approach helps avert costly redesigns and rework, resulting in significant reductions in development time and expenses.

By employing various fault detection techniques at the design stage, engineers can utilize simulation to test fault models against their electronic systems, identifying weaknesses and potential failures efficiently. Early fault detection maximizes reliability and ensures that the final product meets performance standards before fabrication begins.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Importance of Early Detection

Chapter 1 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

By using fault models and simulation tools early in the design process, engineers can identify potential issues before physical prototypes are built.

Detailed Explanation

This chunk emphasizes the primary advantage of early fault detection in the design phase. Engineers utilize fault models and simulation techniques right at the start of the design process. This allows them to predict potential problems in the design of the electronic system without needing to create a physical version of it. By identifying these issues beforehand, they can make adjustments that save time and resources that would otherwise be spent on correcting faults during later stages of development.

Examples & Analogies

Consider a builder who uses blueprints to plan a house before construction begins. If they notice that the layout will lead to poor airflow or sunlight exposure before any materials are purchased or walls are built, they can make changes to the design efficiently. Similarly, in electronic design, catching faults early prevents expensive and labor-intensive revisions later.

Cost Prevention

Chapter 2 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

This early detection helps prevent costly rework and design revisions, reducing development time and expenses.

Detailed Explanation

The second chunk highlights how early fault detection leads to financial savings during the development process. When faults are identified before prototypes are built, the need for redesigns or fixes that would emerge during physical testing is significantly minimized. This saves costs associated with labor, materials, and delays in the project timeline, ultimately leading to a more efficient and cost-effective development process.

Examples & Analogies

Imagine a chef who tastes a dish while cooking before serving it to guests. If they find it too salty, they can adjust the recipe right away, saving time and ingredients. If they wait until it’s served, they might need to start over or issue apologies—leading to waste. In engineering, checking for faults early, like the chef, helps avoid unnecessary costs and revisions.

Key Concepts

-

Early Fault Detection: A strategy to identify potential design issues before physical prototypes are created.

-

Fault Models: Representations of potential faults that help guide testing and simulation.

-

Simulation Tools: Software that allows engineers to predict circuit behavior under fault conditions, facilitating early detection.

Examples & Applications

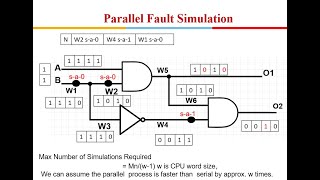

An engineer uses simulation tools to apply stuck-at fault models to a design, identifying potential failures before hardware is built.

A design team employs early fault detection techniques, discovering timing issues early in the development cycle, saving both time and costs.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Catch faults before they grow, saves time and money, this we know.

Stories

Imagine an engineer who designed a complex circuit. Before building a prototype, they ran simulations and discovered a significant issue that would have cost them time and money, preventing a disaster in production—this is the essence of early fault detection.

Memory Tools

To remember the benefits of early fault detection, think 'SAVES': Save time, Avoid costs, Validate design, Enhance reliability, Secure success.

Acronyms

FUSE

Fault Understanding Saves Expenses.

Flash Cards

Glossary

- Fault Models

Abstract representations of potential failures in a circuit used to guide testing strategies.

- Simulation Tools

Software applications that model and predict the behavior of circuits under various fault conditions.

- Cost Reduction

The practice of minimizing expenses associated with design modifications and testing.

- Prototype

An early model of a circuit or system used to test concepts before final production.

- Reliability

The ability of a system or component to consistently perform its intended function without failure.

Reference links

Supplementary resources to enhance your learning experience.