Conclusion

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Importance of Fault Modeling

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're going to discuss the critical role of fault modeling in circuit design. Can anyone explain what fault modeling is?

Isn’t it about identifying how circuits can fail?

Exactly! Fault modeling helps predict faults that might occur in a system. It's essential for developing test strategies. Why do you think this is important?

It probably helps prevent issues before they happen, saving cost and time!

Right on point! Early detection is vital. Remember the acronym 'PREP' – Predict, Reduce costs, Enhance reliability, and Prevent faults.

I like that! It makes it easier to remember.

Great! To summarize, effective fault modeling allows us to design better, more reliable circuits.

Simulation Tools

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Moving on to simulation tools, can anyone name a few?

What about SPICE?

Yes, SPICE is excellent for circuit-level simulation. But why do we need such tools?

They help test circuits without actually building them!

Exactly! This saves time and money. Who can explain what fault coverage analysis is?

It measures how well our test patterns can detect faults, right?

Brilliant! Coverage metrics inform us about the effectiveness of our testing environment. Remember 'CATCH' – Coverage, Analysis, Test, Costs, and Highlights.

Got it! CATCH helps me recall all key aspects.

Limitations and Challenges

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

While modeling and simulation are powerful, let's discuss their limitations. What do you think they might be?

Maybe they can’t cover every fault type?

Correct! Complex faults might slip through. Another limitation is computational cost. Why do you think it's an issue?

Because simulations take a lot of time for large systems?

Exactly! We need to optimize simulations to make them feasible. Always keep in mind the 'DAVE' principle – Dependency on accurate models, Availability of computational resources, Variety of testing methods, and Early detection importance.

That’s a useful way to remember it!

Great! Let's conclude with the understanding that while tools have limitations, they are essential for improving designs and ensuring reliability.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section emphasizes the indispensable role of fault modeling and simulation in the design and testing of electronic circuits, highlighting their utility in predicting faults, optimizing testing processes, and reducing costs while acknowledging their limitations.

Detailed

In conclusion, fault modeling and simulation are fundamental tools in electronic design and testing. These methodologies empower engineers to foresee potential faults during the developmental phase, ensuring systems maintain reliability and performance. Utilizing advanced simulation tools alongside robust fault models allows for high fault coverage and optimized test strategies. This ultimately leads to significant cost savings and enhanced reliability. However, it is essential to recognize the limitations of these tools, such as incomplete fault coverage for complex issues and computational demands, which necessitate a multifaceted approach to fault detection.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Importance of Fault Modeling and Simulation

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Fault modeling and simulation are indispensable tools in the design and testing of electronic circuits.

Detailed Explanation

Fault modeling and simulation are critical processes used in the design of electronic circuits. They enable engineers to anticipate and assess potential faults during the early stages of development, which is crucial for ensuring the final product functions correctly and meets its performance standards.

Examples & Analogies

Think of fault modeling and simulation like a safety check for a car before it leaves the factory. Just as engineers assess potential issues in the car's design to ensure safety and reliability for the driver, electronic engineers use fault modeling to predict mistakes in circuits so electronic devices perform as intended.

Predicting and Analyzing Faults

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

They allow engineers to predict and analyze potential faults early in the development process, ensuring that systems are reliable and meet performance specifications.

Detailed Explanation

By employing fault modeling and simulation, engineers can foresee various issues that may arise during a circuit's operation. This proactive approach allows for adjustments and corrections before the physical prototype is built, which enhances the reliability of the system and ensures it meets specified performance criteria.

Examples & Analogies

Imagine planning a big event. If you are aware of potential problems, such as weather issues or equipment malfunctions, you can prepare solutions in advance. Similarly, engineers anticipate faults in electronic circuits and address them before the final product is created.

Benefits of Simulation Tools

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

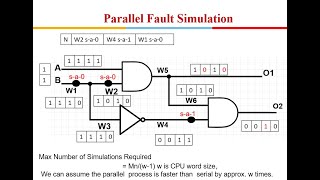

By using advanced simulation tools and fault models, engineers can achieve high fault coverage, optimize test patterns, and reduce the cost and time associated with physical testing.

Detailed Explanation

Advanced simulation tools help engineers evaluate a wide array of possible faults and develop effective testing strategies. With high fault coverage, they can ensure that most issues are identified and corrected earlier, which streamlines the entire development process, making it more cost-effective and efficient.

Examples & Analogies

Consider how a teacher uses practice exams to prepare students for a final test. By providing varied exam questions, the teacher helps the students be ready for almost any question that may appear. In the same way, advanced simulation tools prepare engineers for fault scenarios, improving reliability before the circuit goes into production.

Limitations of Fault Models

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Despite their limitations, fault modeling and simulation remain essential components of modern electronic system development, driving improvements in reliability and robustness across industries.

Detailed Explanation

Although fault modeling and simulation have limitations, such as potentially missing complex fault scenarios or requiring significant computational resources, they are vital in modern design practices. Engineers rely on these methods to systematically improve the reliability and robustness of electronic components in various industries, from telecommunications to medical devices.

Examples & Analogies

It's like a weather forecast: while it provides guidance on what to expect, it cannot predict every natural event accurately. Yet, it is still crucial for planning activities and safety measures. Fault modeling and simulation are similar—they provide valuable insights that enhance our confidence in electronic systems, even though they can't cover everything perfectly.

Key Concepts

-

Fault Modeling: A process to foresee potential circuit failures.

-

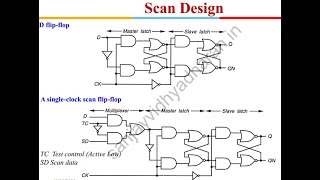

Simulation Tools: Instruments for testing circuit behavior under simulated faults.

-

Fault Coverage: The effectiveness of our testing to catch faults.

Examples & Applications

Using SPICE to simulate an analog circuit and test its response to open circuit faults.

Employing Monte Carlo simulations to ensure reliability amid component tolerances.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

In circuits where faults might arise, simulate them well to avoid surprise.

Stories

Imagine building a bridge. You check its blueprints and model potential damages before construction to ensure safety.

Memory Tools

Remember 'CATCH' for fault coverage: Coverage, Analysis, Test Patterns, Costs, and Highlights.

Acronyms

Use 'DAVE' for limitations

Dependency

Availability

Variety

Early detection.

Flash Cards

Glossary

- Fault Modeling

The process of defining and representing potential faults that can occur in electronic circuits.

- Simulation Tools

Software tools used to model and analyze the behavior of circuits under various fault conditions.

- Fault Coverage Analysis

The measurement of how many faults are detectable by a given set of test patterns.

- Computational Cost

The resources and time required to perform simulations, often significant for complex designs.

Reference links

Supplementary resources to enhance your learning experience.