Introduction to Fault Modeling and Simulation

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Importance of Fault Modeling

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's begin by discussing the importance of fault modeling in electronic design. Can anyone tell me what fault modeling means?

Is it about figuring out what kinds of faults might happen in a system?

Exactly! Fault modeling helps us define potential faults that can occur, allowing us to prepare for them. It's crucial for creating reliable systems. Does anyone know why we need to identify faults before manufacturing?

To avoid spending more on fixing problems later?

Right! Early fault detection saves costs and time. Remember: 'Find faults early to save money!' That's a good mnemonic to keep in mind.

Simulation Tools

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now that we understand fault modeling, let's talk about simulation tools. What do these tools do?

They test how a circuit behaves under different fault conditions?

Absolutely! Simulation tools allow us to assess how the system reacts to the defined fault models. For instance, can anyone name a couple of types of simulations we might use?

Boolean Fault Simulation and Timing Fault Simulation?

Very good! Boolean Fault Simulation checks if faults are detectable with certain test vectors, while Timing Fault Simulation checks for delays. Remember the acronym BFT - Boolean Fault, Testing.

Fault Coverage

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Lastly, let's discuss fault coverage analysis. Why do you think measuring fault coverage is important?

It shows us how many faults our tests can detect, right?

Exactly! Higher fault coverage means our system is more thoroughly tested. Can anyone tell me how coverage analysis can be performed?

Using simulation tools that provide fault coverage metrics?

You're spot on! Tools like Synopsys DFT Compiler and Mentor Graphics Tessent help with this. Just remember: 'More coverage, more reliability!' That's another good memory aid.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section introduces fault modeling and simulation as essential techniques in electronic design. It explains how fault modeling defines potential faults in systems and how simulations assess system behavior under these fault conditions, enabling improvements in reliability and test coverage.

Detailed

In modern electronic design, particularly within integrated circuits (ICs) and systems-on-chip (SoCs), fault modeling and simulation play critical roles in anticipating and analyzing potential system faults prior to the manufacturing phase. Given the increasing complexity of electronic systems, ensuring their reliability has become a challenge that requires comprehensive fault detection strategies. Fault modeling involves the specification of various types of faults that might occur, while simulation tools facilitate the evaluation of system behavior under these defined fault conditions. As this section unfolds, it will emphasize the importance of identifying weak design points, optimizing test coverage, and ultimately enhancing overall system reliability.

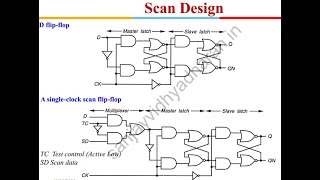

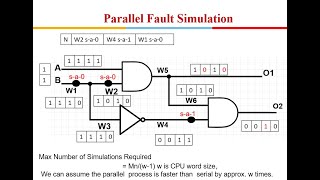

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Importance of Fault Modeling and Simulation

Chapter 1 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

In modern electronic design, fault modeling and simulation are vital tools used to predict and analyze potential faults in a system before manufacturing.

Detailed Explanation

Fault modeling and simulation are essential in electronics because they allow designers to foresee problems that might occur in a system. This foresight is crucial before any physical manufacturing takes place, helping to prevent costly mistakes and ensuring that the product works correctly.

Examples & Analogies

Think of fault modeling like a fire drill in a school. Before the real emergency, students practice how to exit the building safely. Similarly, fault modeling allows engineers to practice handling potential failures before a product is built.

Challenges with Growing Complexity

Chapter 2 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

As integrated circuits (ICs) and systems-on-chip (SoCs) grow in complexity, ensuring reliability through comprehensive fault detection becomes more challenging.

Detailed Explanation

With the increasing complexity of today's electronic components, such as ICs and SoCs, it becomes harder to ensure that all possible faults are identified and handled. More components mean more potential for things to go wrong, which can complicate fault detection efforts.

Examples & Analogies

Imagine trying to find a single malfunctioning light bulb in a massive Christmas light display. With so many bulbs intertwined, finding the faulty one can be incredibly challenging, just as identifying faults in complex circuits can be.

Concepts of Fault Modeling and Simulation

Chapter 3 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Fault modeling involves defining specific types of faults that could occur in a system, while simulation tools allow engineers to apply these fault models to evaluate the behavior of the system under different fault conditions.

Detailed Explanation

Fault modeling is about identifying which kinds of faults might happen in a system—essentially predicting the issues. Simulation tools then let engineers use these models in a controlled environment to see how the system reacts when faults are present, helping them to pinpoint vulnerabilities.

Examples & Analogies

Consider a car manufacturer that conducts crash tests. They create models of different types of crashes (like a head-on collision) and then simulate these scenarios to see how the vehicle holds up. Similarly, engineers model electronic faults and simulate them to see how the circuit behaves.

Benefits of Fault Modeling and Simulation

Chapter 4 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Fault modeling and simulation help identify weak points in a design, optimize test coverage, and enhance system reliability.

Detailed Explanation

By employing fault modeling and simulation, engineers can locate areas within the design that are prone to failure. This proactive approach allows for the creation of tests that better cover these weak areas, which ultimately leads to enhanced reliability of the system, minimizing the chances of failure during actual use.

Examples & Analogies

It's like a coach reviewing game footage to find flaws in a team's play. The coach identifies weaknesses and works on drills to improve performance, leading to a stronger overall team. Similarly, engineers use simulation to shore up weaknesses in designs.

Overview of the Chapter's Content

Chapter 5 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

In this chapter, we will explore the development of fault models, the different types of faults, and how simulation tools are used to predict and analyze faults in electronic circuits.

Detailed Explanation

This chapter will provide a deep dive into how engineers create fault models, discuss various fault types—both in digital and analog circuits—and illustrate how simulation tools can predict how these faults will affect performance. It sets a comprehensive framework for understanding the role of fault modeling and simulation in electronic design.

Examples & Analogies

Think of this chapter like a comprehensive guide to preparing for a big exam. It covers the essential theories (fault models), different types of exam questions (fault types), and strategies for answering them (simulation tools), helping students grasp the subject thoroughly.

Key Concepts

-

Fault Modeling: A technique to define potential faults that might occur in electronic systems.

-

Simulation Tools: Software used to model circuit behavior under fault conditions.

-

Fault Coverage: A metric measuring the effectiveness of testing in identifying faults.

-

Fault Injection: An approach to test a system's response to various faults.

Examples & Applications

A stuck-at fault where a signal is fixed at a logic high state.

Delay fault causing a system to miss its timing requirements due to slow signal propagation.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Before we build, let's find the faults, a cost-saving plan that never halts.

Stories

Think of a wizard who can see all the potential mistakes in his spells, ensuring he never surprises himself with failure.

Memory Tools

BFT for Fault Simulation: Boolean Faults Tested.

Acronyms

FAM - Fault Awareness Model

Always be aware of potential faults.

Flash Cards

Glossary

- Fault Modeling

The process of defining specific types of faults that could occur in a system to prepare for potential failures.

- Simulation

A technique used to model and test the behavior of a circuit under various fault conditions.

- Fault Coverage

The measure of the effectiveness of test patterns in detecting faults within a circuit.

- Fault Injection

The process of introducing faults into a circuit during simulation to test its fault tolerance.

Reference links

Supplementary resources to enhance your learning experience.