Comprehensive Fault Coverage

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Importance of Fault Coverage

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're diving into comprehensive fault coverage. Can anyone explain why fault coverage is important in circuit design?

I think it's because it helps ensure that the circuit performs reliably under different fault conditions.

Exactly! Comprehensive fault coverage helps identify potential weak points in a design. It's a key to enhancing system reliability. We often use simulation tools to help achieve this. Who can remind me what we mean by simulation tools?

Simulation tools allow us to test our designs without needing physical prototypes, right?

That's correct! These tools help run various fault scenarios to see how the design behaves. This way, we can address vulnerabilities before manufacturing.

But how do we measure fault coverage?

Great question! Fault coverage is measured as a percentage. The goal is to detect as many faults as possible. Remember, higher coverage means a more robust system!

To wrap up, can someone summarize why comprehensive fault coverage is vital?

It helps ensure reliability by detecting faults early and optimizing the design before production.

Simulation Tools in Fault Detection

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s dive deeper into how simulation tools support fault detection. What types of faults do we typically simulate?

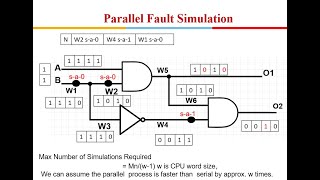

We usually simulate stuck-at faults and transition faults, right?

Yes, and don't forget delay faults and bridging faults! These models are crucial for testing the reliability of our circuits under various conditions.

So, when we run simulations, how do we determine if our test patterns are effective?

Good point! We analyze fault coverage metrics to see how many of the simulated faults our patterns can detect. Continuous analysis helps us optimize the tests.

And this helps us avoid costly redesigns later, right?

Absolutely! By ensuring comprehensive fault coverage, we catch issues early in the design, making the process more efficient.

As a final thought, can anyone share why relying solely on simulation might not be enough?

There may be complex faults that simulations don’t catch, so we might still need additional testing methods.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

In this section, we discuss the importance of comprehensive fault coverage in electronic design, detailing how simulation tools facilitate exhaustive fault coverage analysis, enhancing the reliability of systems by identifying and addressing weak points.

Detailed

Comprehensive Fault Coverage

Comprehensive fault coverage refers to the thorough analysis and testing of electronic designs to ensure they are robust against a variety of potential faults. This section emphasizes the role of simulation tools in achieving exhaustive fault coverage during the design verification process. By utilizing these tools, engineers can simulate various fault conditions and assess the effectiveness of their test patterns. A higher percentage of detected faults signifies a more comprehensive testing suite, contributing to enhanced system reliability and performance. Additionally, the use of coverage metrics provided by simulation tools assists in evaluating the necessity for further testing, ensuring that all critical faults are being addressed. Overall, comprehensive fault coverage is essential for increasing the robustness of electronic systems against failures.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Overview of Comprehensive Fault Coverage

Chapter 1 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Simulation tools allow for exhaustive fault coverage analysis, ensuring that the design has been tested for a wide range of potential faults. This enhances the reliability and robustness of the system, ensuring it can withstand various fault conditions.

Detailed Explanation

This section explains the importance of comprehensive fault coverage in the context of electronic design. It highlights how simulation tools facilitate a rigorous analysis of potential faults. By using these tools, engineers can ensure that a system has been tested against many possible failure scenarios, making the system more reliable. This means that if a fault occurs in real-world use, the system is more likely to handle or recover from it effectively.

Examples & Analogies

Imagine a safety net used in a circus performance. Just as the net is designed to catch performers in case they fall, comprehensive fault coverage acts as a safety measure for electronic designs. If there are faults in the system, the simulation tools ensure these faults are identified and addressed, much like how the safety net prepares for unexpected falls, maintaining safety during performances.

Benefits of Comprehensive Fault Coverage

Chapter 2 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

This enhances the reliability and robustness of the system, ensuring it can withstand various fault conditions.

Detailed Explanation

Comprehensive fault coverage directly contributes to the robustness of electronic systems. It ensures that systems are tested for numerous fault conditions that might occur during their operational life. The result is a design that can not only function as expected under normal circumstances but can also adapt or survive when unexpected faults happen. The implication is that the end product is safer, more efficient, and has a longer lifespan, which is crucial in industries like automotive or healthcare where reliability is paramount.

Examples & Analogies

Consider a smartphone that's been thoroughly tested for various scenarios—water spills, drops, or extreme temperatures. Just as each potential mishap has been accounted for in the phone's design and testing to ensure it works no matter the situation, comprehensive fault coverage in circuit design ensures that all possible faults are considered and mitigated. This leads to a more user-friendly and dependable product.

Key Concepts

-

Comprehensive Fault Coverage: Thorough examination and testing of circuits to ensure reliability.

-

Simulation Tools: Tools that allow the testing of circuit designs virtually, enabling cost-effective fault detection.

-

Fault Coverage Metrics: Statistics used to measure the effectiveness of test patterns in detecting faults.

Examples & Applications

Using simulation tools to detect stuck-at faults in a digital circuit helps improve reliability.

Analyzing fault coverage metrics to identify weak points in the test patterns and optimizing them for better detection rates.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Check each fault without a doubt, coverage ensures robustness throughout.

Stories

Imagine a castle with many doors (faults). The guards (test vectors) check each one to keep the castle safe (reliable).

Memory Tools

F-C-S: Fault Coverage is Secure - remember the importance of securing your design!

Acronyms

C-F-C

Comprehensive Fault Coverage - it’s what keeps your designs ready for battle!

Flash Cards

Glossary

- Fault Coverage

The percentage of detected faults by a test pattern in an electronic circuit.

- Simulation Tools

Software applications used to test the behavior of designs under various conditions without physical prototypes.

- Test Vectors

Sets of input patterns used to verify the functionality of an electronic circuit.

Reference links

Supplementary resources to enhance your learning experience.