Functional Simulation

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Functional Simulation

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we are going to discuss functional simulation, a key part of ensuring that our circuits work correctly before we build them. Can anyone tell me why simulation might be important?

It helps us see if everything will work as expected without actually making the circuit, right?

Exactly! By simulating the circuit, we can check outputs for given inputs. This helps us identify errors early on.

What does a testbench do in this process?

Great question! A testbench encompasses input vectors, expected outputs, and timing information to evaluate our circuit. Think of it as a way to set up a controlled environment to verify function.

And what if the circuit doesn’t respond correctly?

That's where fault injection comes in! We can introduce specific faults during simulation to see how robust our design is against real-world issues.

To summarize, functional simulation employs testbenches and fault injection to verify if circuits behave as expected before they are built.

Components of Functional Simulation

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now that we understand the basics, let’s dig deeper into testbenches. What elements do you think a good testbench should have?

It should include different input scenarios, right?

Correct! Inputs need to cover a range of conditions to adequately test the circuit. We also need expected outputs for comparison.

Is there a specific way to structure these inputs?

Yes, we typically structure test cases based on conditions we expect in real-world operation. Also, think of edge cases to ensure reliability.

What about fault injection; can you give an example of that?

When performing fault injection, you might simulate a stuck-at fault to see how the circuit behaves if one of its signals permanently holds a high or low value. This helps to assess robustness against faults.

To summarize, a well-structured testbench encompasses diverse inputs and expected outputs, while fault injection examines circuit behavior under fault conditions.

Practical Applications of Functional Simulation

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s explore how functional simulation is applied in actual engineering processes. Can anyone suggest a scenario where functional simulation might be vital?

Maybe in a safety-critical system, like in automotive or aerospace?

Absolutely! In such fields, ensuring that circuits operate correctly under all conditions is crucial for safety.

What if we find a fault during the simulation?

Good catch! If a fault is detected, we can revise the design before manufacturing, avoiding costly corrections down the line.

Does functional simulation only work for digital circuits?

Not at all! It can be adapted for analog circuits too. The principles remain similar, focusing on verifying response to inputs.

To summarize, functional simulation is especially critical in fields like automotive and aerospace, allowing us to catch faults early and adapt designs before fabrication.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section delves into functional simulation, focusing on how it helps in verifying whether a circuit produces the correct outputs for specified inputs. It discusses the critical roles of testbenches and fault injection in ensuring design reliability and robustness against potential faults.

Detailed

Functional Simulation

Functional simulation serves as a crucial technique in verifying the logical correctness of electronic circuit designs prior to physical testing. It ensures that the system operates as intended by checking that the outputs align with expected results for a variety of input scenarios.

Key components of functional simulation include:

- Testbenches: These are constructed scenarios featuring input vectors, anticipated outputs, and clock cycles to effectively simulate the operation of the circuit under typical conditions. They provide a structured environment for verifying functionality and catching potential design flaws.

- Fault Injection: This process involves intentionally introducing faults during the simulation to evaluate how the system reacts. It assesses the fault tolerance of the design, ensuring that it can cope with real-world malfunctions.

As integrated circuits become more complex, functional simulation becomes ever more critical for maintaining design integrity and operational reliability.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Overview of Functional Simulation

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Functional simulation is used to verify the logical correctness of a circuit before physical testing. It checks whether the system produces the correct outputs for the given inputs, often using testbenches that simulate various operating conditions.

Detailed Explanation

Functional simulation is an essential step in the electronic design process. It allows engineers to test the design to ensure that it behaves as expected under various input scenarios before any physical iteration is created. During this simulation, the circuit's outputs are compared against the expected outputs based on the provided inputs to see if they match. If they do, this indicates that the circuit is functioning correctly according to its specifications.

Examples & Analogies

Think of functional simulation like a rehearsal before a stage performance. Just like actors practice their lines and scenes to ensure everything goes smoothly on opening night, engineers run functional simulations to confirm that their circuit designs collectively work as intended before they build the actual product.

Understanding Testbenches

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

A testbench is a set of input vectors, expected outputs, and clock cycles used to test the functionality of a circuit. It ensures that the circuit functions correctly under normal conditions and helps detect potential design errors.

Detailed Explanation

A testbench serves as a controlled environment where specific tests are designed. It consists of various input vectors, which are specific combinations of input values fed into the circuit. With these, engineers define what outputs they expect. The testbench continually checks—like a real-world scenario—the actual outcomes produced by the circuit. This systematic process helps in pinpointing any discrepancies or errors that may need fixing.

Examples & Analogies

Consider a testbench similar to a quiz for students. Just like a quiz has questions (input vectors) and the correct answers (expected outputs), a testbench evaluates how well the circuit performs against the set criteria, revealing any areas needing improvement before the final assessment.

Fault Injection in Functional Simulation

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

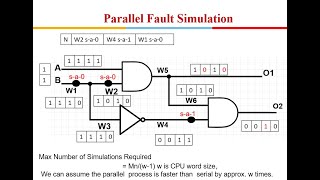

In functional simulation, fault injection can be used to simulate faults in the design and observe how the system responds. This allows engineers to assess the fault tolerance of the design and ensure it can handle real-world faults effectively.

Detailed Explanation

Fault injection is a critical technique in functional simulation. It involves deliberately introducing faults into the design to see how the system behaves under these compromised conditions. By simulating various fault scenarios, engineers can evaluate the robustness and fault tolerance of the design. The insights gained from fault injection help in assessing whether the system can reliably operate despite potential real-world issues that could lead to failures.

Examples & Analogies

Fault injection can be compared to testing a car's safety features by intentionally creating simulated collision scenarios. Just as engineers study how airbags deploy and seatbelts perform in a crash test, engineers use fault injection to ensure the circuit responds appropriately to unexpected faults, thus ensuring safety and reliability in its operation.

Key Concepts

-

Functional Simulation: A technique used to ensure circuit behavior aligns with expected outputs.

-

Testbench: An essential component utilized to validate circuit performance using structured inputs and expected outcomes.

-

Fault Injection: A method employed to introduce errors in a simulation to test the circuit's fault tolerance.

Examples & Applications

Using a testbench that simulates various input signals and timing sequences to verify the performance of a flip-flop circuit.

Injecting a fault such as a stuck-at-1 condition into a digital circuit simulation to evaluate how the output behaves under error conditions.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Simulation's a location to check before creation, keep your circuit in the right equation!

Stories

Imagine a chef who tests all the spices in a dish before serving, ensuring everything's just right. That’s how we test our circuits with functional simulation!

Memory Tools

Remember 'TIF' for Testbench, Inputs, and Fault Injection - three components for effective functional simulation!

Acronyms

FAST

Functional Analysis with Simulations for Testing - remembering the essence of functional simulation!

Flash Cards

Glossary

- Functional Simulation

A method of verifying the logical correctness of a circuit by simulating its behavior under various input conditions before physical testing.

- Testbench

A collection of input vectors, expected outputs, and clock cycles created to validate the functionality of a circuit.

- Fault Injection

The process of deliberately introducing faults into a system during simulation to assess its response and fault tolerance.

Reference links

Supplementary resources to enhance your learning experience.

- Overview of Functional Simulation

- Testbench Design for Digital Circuits

- Introduction to Fault Injection

- Digital Logic and Functional Simulation

- Understanding Testbenches

- Fault Simulation and Injection Techniques

- The Role of Functional Simulation in Circuit Design

- SPICE and Circuit Analysis

- Fault Tolerance in Digital Circuits