Cost Reduction

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Cost Reduction

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're focusing on how cost reduction plays a critical role in electronic design. Can anyone tell me why reducing costs is essential?

It's important to save money when developing products!

Exactly, Student_1! Reduced costs allow for competitive pricing and increased profit margins. One way we achieve this in electronic design is through simulation tools. Who can explain how they might help in reducing costs?

They save money by avoiding physical prototypes, right?

Great point, Student_2! By simulating designs, we can catch potential issues early, avoiding the expensive rework that comes from late-stage problems.

So we don't have to build as many prototypes to test ideas?

Exactly! Reducing prototypes directly cuts costs and speeds up the design process. Remember, early detection saves money—think of it as catching a leak before it floods a basement.

In summary, utilizing simulation tools prevents costly errors and enhances efficiency in design development.

Financial Impact of Simulation

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s delve deeper into the financial impact of simulation. Why do you think simulation tools lead to overall cost savings?

Because we find problems faster?

Precisely, Student_4! They allow us to test various scenarios without the high costs of fixing physical devices. Can anyone think of how this might also improve testing efficiency?

If we can run multiple tests simultaneously, it shortens the testing time.

Exactly! Faster testing means less time spent in development, which translates to lower costs. Always remember: time is money!

So it’s basically a win-win situation!

Correct! The efficiencies gained can improve the product’s market readiness. In summary, effective simulation not only reduces costs but also promotes timely product launches.

Long-Term Cost Benefits

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s look at the long-term benefits of using simulation in fault modeling. Why is it crucial for ongoing cost management?

It helps teams keep refining designs over time without huge costs?

Right, Student_3! Continuous improvements can be made without the fear of spiraling costs that come from traditional methods. Does anyone else want to add?

Does it also mean we can integrate new technology more smoothly?

Absolutely! Adapting to technological changes is cheaper and easier with simulations. Less downtime means more productivity!

To conclude this session, embracing simulation in fault modeling not only saves costs now but fosters a culture of innovation and continuous enhancement.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The section discusses the financial benefits of using simulation and fault modeling in electronic design. It emphasizes how simulation reduces the need for extensive physical testing, thus cutting down on costs associated with hardware iterations and prototype development.

Detailed

Cost Reduction

In electronic design, cost reduction is a crucial objective achieved through the utilization of simulation tools and fault modeling. By allowing designers to experiment with and evaluate circuit designs virtually, these techniques diminish the necessity for expensive hardware testing and prototyping. The section highlights how fault modeling and simulation enable engineers to identify issues early in the design phase, leading to significant savings in development time and expenses. Consequently, simulation fosters a more cost-effective approach to developing reliable electronic systems, driving overall efficiency in the design process.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Simulation Testing

Chapter 1 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Simulation allows designers to test and evaluate circuit designs without the need for extensive hardware testing.

Detailed Explanation

This chunk discusses how simulation tools provide a way to test circuit designs in a virtual environment, which eliminates the need for physical prototypes. This means that engineers can experiment with and refine their designs quickly and efficiently without incurring the costs associated with creating multiple versions of a hardware prototype.

Examples & Analogies

Think of it like testing a recipe in a virtual kitchen before cooking it in a real kitchen. By using a simulation tool, you can try different ingredients and cooking methods without wasting any food or time on actual cooking. If the recipe doesn’t work, you can simply adjust it in the simulation and try again until you get it right.

Cost Reduction Benefits

Chapter 2 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

This reduces the cost associated with physical testing and prototype iterations, making the development process more cost-effective.

Detailed Explanation

By utilizing simulation tools, companies can significantly lower their testing expenses. Instead of allocating large budgets for materials and labor involved in manufacturing prototypes, they can simulate the testing of designs. This leads to fewer resources spent on physical testing and allows the team to focus funds on other critical areas of development.

Examples & Analogies

Imagine you're a car manufacturer deciding to test new designs. Instead of building physical cars for every new model, you use software to simulate how the car will perform under various conditions. This way, you save on materials and labor costs, allowing you to invest in better technology or design improvements.

Key Concepts

-

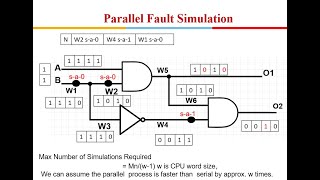

Fault Modeling: Describes potential faults to improve the reliability of electronic designs.

-

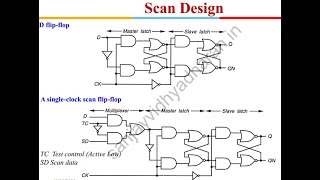

Simulation Tools: Allow engineers to test designs virtually, preventing physical prototyping.

-

Cost Efficiency: Achieving lower costs through optimization and early fault detection.

Examples & Applications

Early identification of design flaws through simulation can prevent the need for costly hardware iterations.

Using simulation tools allows for extensive testing without physical prototypes, saving both time and resources.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

When designs go through simulation's call, mistakes find their way, saving dollars for all.

Stories

A young engineer named Sam discovered that by simulating his circuits, he caught potential issues early, saving his company from spending thousands on prototypes that wouldn't work.

Memory Tools

C.R.E.S.T: Cost Reduction, Reliability, Efficiency, Simulation Tools, Testing.

Acronyms

SAVE

Simulation Abates Valuable Expenses.

Flash Cards

Glossary

- Cost Reduction

Processes that lower the costs associated with manufacturing and testing electronic designs.

- Simulation Tools

Software that allows the modeling of circuit behavior for testing without physical prototypes.

- Fault Modeling

The process of outlining potential faults in electronic designs to predict issues during operation.

Reference links

Supplementary resources to enhance your learning experience.