Optimized Test Patterns

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Understanding Optimized Test Patterns

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we’re going to discuss optimized test patterns. Who can tell me why optimizing test patterns is important in electronic design?

I think it's because it helps in detecting faults more efficiently.

Exactly! Optimizing test patterns allows us to detect faults more effectively. Can anyone explain how simulation tools play a part in this?

They help us test different fault models before the hardware is even made.

Well done! By simulating faults, engineers can analyze how the test patterns perform against various fault models.

Does this mean we can avoid some physical testing?

Correct! Fewer physical tests save time and cost. Let’s summarize: optimized test patterns lead to better fault detection and efficiency.

Fault Coverage Analysis

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, let’s explore fault coverage analysis. Why is measuring fault coverage crucial?

It shows how many potential faults our test patterns can detect.

Exactly! Higher fault coverage indicates a more comprehensive testing process. Can someone explain how we assess fault coverage?

We compare detected faults against total possible faults.

Right again! This assessment helps us determine if we need additional test patterns. Remember: comprehensive fault coverage is key to reliability.

Practical Applications

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now that we understand what optimized test patterns are, let’s discuss their practical application. Can anyone provide an example?

Like how companies use these patterns in production testing?

Yes! For instance, manufacturers utilize optimized patterns to ensure that circuits pass tests efficiently. Why do you think testing time matters?

Because reducing time can lower production costs!

Correct! In high-volume production, minimizing testing time can significantly impact overall cost and efficiency. Let’s conclude by emphasizing the balance of quality and efficiency.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section discusses how engineers utilize simulation and fault analysis to create optimized test patterns that improve the efficacy of fault detection in electronic systems, ensuring reliability and reducing testing time.

Detailed

Optimized Test Patterns

Optimized test patterns are crucial in enhancing the efficiency of fault detection during the testing phase of electronic designs. This section highlights how simulation tools and fault coverage analyses are utilized by engineers to develop effective test patterns that maximize the detection rate of potential faults while minimizing the time and resources spent on testing. By leveraging comprehensive fault modeling, engineers can devise patterns that effectively expose weaknesses in circuit designs, thus allowing for earlier intervention and correction of potential design flaws. The ultimate goal of implementing optimized test patterns is to ensure reliable system performance while adhering to tight production timelines.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Optimization of Test Patterns

Chapter 1 of 1

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

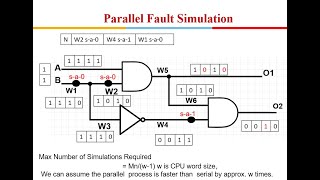

By simulating faults and analyzing test coverage, engineers can optimize the test patterns used in production. This leads to more efficient and effective testing, reducing the overall testing time and improving the fault detection rate.

Detailed Explanation

This chunk discusses how engineers improve the way they test systems by using fault simulations. When engineers simulate faults, they can see how different test patterns perform in identifying problems in the design. By analyzing this data, they can refine the test patterns they use during actual production. The goal of this optimization is twofold: to make the testing process faster and to increase the likelihood that any faults are detected before the product goes to market.

Examples & Analogies

Consider a coach preparing a sports team for a big game. The coach watches videos of previous games to analyze the team's strengths and weaknesses. Based on this analysis, the coach designs more effective training drills tailored to improve areas that need work. Similarly, engineers use simulations to refine their test patterns, ensuring that every potential failure point is examined, much like a coach ensuring all players are prepared.

Key Concepts

-

Optimized Test Patterns: Essential for efficient fault detection and reduced testing time.

-

Fault Coverage: Critical metric that indicates the effectiveness of test patterns.

-

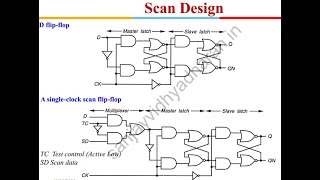

Simulation Tools: Integral in developing and evaluating optimized test patterns.

-

Fault Detection: Core goal in the design and testing phase.

Examples & Applications

Using optimized test patterns in a high-speed digital circuit to detect transition faults efficiently.

Simulating fault scenarios using software tools to assess potential weaknesses in circuit designs.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Test patterns optimized, faults can’t hide, Reliable circuits take pride!

Stories

Imagine a factory where engineers use magical patterns to reveal hidden faults in each circuit, ensuring that only the strongest pieces travel to the market.

Memory Tools

Remember: O.C.A (Optimized Coverage Analysis) - Always aim for higher fault coverage.

Acronyms

FOCUS

Fault detection

Optimization

Coverage

Understand

Simulate.

Flash Cards

Glossary

- Optimized Test Patterns

Strategically designed sequences of test inputs used to maximize fault detection while minimizing testing time.

- Fault Coverage

A measure of the proportion of detectable faults identified by test patterns in a circuit.

- Simulation Tools

Software applications used to model and analyze the behavior of circuits under various conditions.

- Fault Detection

The process of identifying faults or failures within a system or component.

Reference links

Supplementary resources to enhance your learning experience.