Dependency on Accurate Models

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Importance of Accurate Fault Models

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're discussing the dependency of fault simulation on accurate models. Can anyone tell me why accuracy in fault modeling is vital for circuit reliability?

I think if the models are wrong, then the simulation results won't reflect the true behavior of the circuit.

Exactly! Inaccurate models can lead to false positives, meaning designs might fail criteria when they shouldn't. Can anyone think of an example?

Maybe a model for a stuck-at fault could mistakenly indicate that everything's fine when there's actually a real fault?

That's right! If we assume a fault is detected incorrectly, we might overlook critical issues. This highlights the importance of thorough validation. Remember the acronym 'ACCURATE'—Assure Correctness, Utilize Reliable Analysis Techniques, Execute testing rigorously!

Consequences of Inaccurate Fault Models

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's delve deeper into what happens when we use inaccurate fault models. Besides false positives, what else might we face?

If the models are not complete, we might miss out on identifying actual faults.

Correct! Missing faults can lead to devastating failures post-manufacture. Can someone give an example of the kind of faults we might miss?

Maybe delay faults? If the simulation doesn't account for them, a circuit could operate out of its intended timing.

Exactly! So, the consequences of poor modeling extend beyond detection issues. We need to consider system reliability holistically. Let's take a moment to summarize—accurate models equate to reliable simulations, and missing fault detection can be catastrophic.

The Role of Validation in Fault Models

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

To address these challenges, how can we ensure our fault models remain accurate?

I think we need to constantly validate them against real-world tests and benchmarks.

Great insight! Continuous validation is key. How can we implement this effectively?

We could use previous designs to compare expected faults against actual test results.

Yes! This cycle enhances model reliability significantly. Remember the mnemonic 'VALIDATE'—Verify, Analyze, Look for discrepancies, Iterate, Test thoroughly, Ensure precision.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Accurate fault models are essential for the effectiveness of fault simulation in electronic design. This dependency can lead to false positives or undetected faults, emphasizing the need for precision and completeness in modeling to enhance reliability.

Detailed

Dependency on Accurate Models

The accuracy of fault simulation is heavily reliant on the precision of the fault models employed. In electronic circuit design, fault modeling serves as a framework that determines how various faults are defined and subsequently simulated. If these fault models are inaccurate or incomplete, the consequences can be severe, leading to false positives—incorrectly indicating that a fault exists when it does not—or failing to detect actual faults. This section emphasizes that such inaccuracies can compromise the reliability of electronic systems significantly.

Understanding fault models ensures that engineers can predict how circuits will behave under fault conditions accurately. Thus, a comprehensive and precise modeling process is vital for achieving effective fault detection, ensuring that designs maintain their integrity and performance under potential fault scenarios. In summary, this dependency on accurate models stresses the importance of thorough validation and verification of fault models in the development of reliable electronic systems.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Importance of Model Accuracy

Chapter 1 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

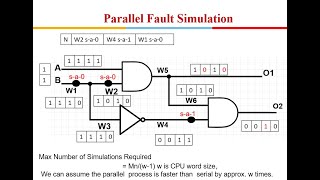

The effectiveness of fault simulation depends on the accuracy of the fault models used.

Detailed Explanation

Fault simulations rely heavily on the models that represent potential faults in a system. If these models accurately reflect how faults occur in real scenarios, the simulations will yield useful and reliable results. However, if the fault models are inaccurate or not comprehensive, they can produce misleading results, such as suggesting that a fault exists when it does not (false positive) or failing to identify a real fault (missed fault). This highlights the critical nature of having precise and detailed fault models to ensure simulation results are valid.

Examples & Analogies

Think of a fault model as a weather forecast. If the forecast accurately predicts a storm, people can prepare and take precautions. However, if the forecast is wrong or misses out on key details, like the storm’s strength or path, people may not prepare adequately for the severe weather. Similarly, accurate fault models help engineers prepare for potential issues in electronic designs.

Consequences of Inaccuracy

Chapter 2 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Inaccurate or incomplete models may lead to false positives or missed faults, which could impact the reliability of the system.

Detailed Explanation

When models are flawed, they can result in two major issues: false positives and missed faults. A false positive means that the simulation indicates a problem exists when, in fact, there is none. This can lead to unnecessary redesigns or scrapping of components. On the other hand, a missed fault happens when the simulation overlooks an actual issue that can cause the system to fail post-manufacturing, leading to possible system breakdowns or safety hazards. Both situations can severely impact the reliability of the electronic system being designed.

Examples & Analogies

Imagine you're scanning your home for security threats using an alarm system. If the system falsely indicates a window is open when it's not, you'll waste time checking and worrying unnecessarily. Alternatively, if the system fails to notify you about an actual break-in, the consequence could be severe. Accurate security measures are crucial, just like accurate fault models are essential for reliable electronic designs.

Key Concepts

-

Accuracy in Fault Models: Essential to prevent false positives or missed detections.

-

Validation of Models: Continuous verification enhances reliability.

-

Consequences of Inaccuracy: Missing faults can lead to system failures.

Examples & Applications

If a stuck-at fault model mistakenly indicates that a signal will always be high, an actual fault could go undetected.

Delay faults that affect signal timing may not be caught if the model does not account for timing variations.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Accurate models lead to success, without them we can't progress!

Stories

Once in an electronics lab, a team built a circuit based on a faulty model; they learned the hard way that accuracy in their designs was essential when the prototype failed during testing.

Memory Tools

Remember the 'VALIDATE'—Verify, Analyze, Look for discrepancies, Iterate, Test thoroughly, Ensure precision.

Acronyms

ACCURATE—Assure Correctness, Utilize Reliable Analysis Techniques, Execute testing rigorously.

Flash Cards

Glossary

- False Positive

An incorrect indication of a fault when no actual fault is present.

- Fault Model

An abstraction that represents potential faults in a system.

- Fault Detection

The process of identifying faults in a system.

- Reliability

The ability of a system to perform consistently under specified conditions.

Reference links

Supplementary resources to enhance your learning experience.