High Computational Cost

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Computational Costs in Simulations

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's begin our discussion today with the concept of computational costs in simulations. Can anyone share what they think computational cost refers to in the context of simulations?

I think it might relate to the time and resources needed to run the simulations?

Exactly, great point! Computational cost is about the time and processing power required to run these simulations. Why do you think it's particularly high in large systems?

Perhaps it's because there are so many variables to account for?

Absolutely! More complex systems have more components, which means the simulations need to process a lot more information. This leads us to why optimization in simulation runs is crucial. Can anyone think of a strategy to address high computational costs?

Maybe running simulations in parallel?

Correct! Running simulations in parallel can significantly cut down on processing time. Remember, efficiency is key when dealing with complex designs!

Trade-offs of Optimization Techniques

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now that we’ve touched upon optimization, let's delve deeper. What do you think could be some trade-offs associated with optimizing simulations?

Maybe sacrificing accuracy for speed?

Exactly! While we can speed up simulations, there's also a risk of not capturing every fault or behavior accurately, which is crucial for reliability analysis. How do you think we balance this concern?

We might need to weigh the importance of certain components or faults against the time we have!

Great insight! Prioritizing components or simulations based on their criticality can help maintain a balance between efficiency and thoroughness. What might be a disadvantage of high computational costs in terms of project timelines?

It could delay the entire development process since we need more time for simulations.

Right! Thus it's important for teams to have effective strategies in place early in the design process. Remember: managing these costs can greatly affect overall project success!

Practical Applications of Computational Cost Management

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s connect what we’ve learned to real-world applications. In what situations do you think managing computational costs is most critical?

Maybe in industries where safety is critical, like aerospace?

Absolutely! Industries like aerospace require rigorous testing. Can anyone think of another industry that heavily relies on simulations?

Automotive could be another, especially with self-driving cars.

Exactly! The automotive industry needs to ensure safety in various driving conditions. This brings us back to optimizing simulations and handling high computational costs. It’s a balance we must always consider.

So in a nutshell, high computational costs require strategic planning and optimization to ensure both efficiency and reliability.

Well summarized! Always remember, our goal is to create reliable systems efficiently.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

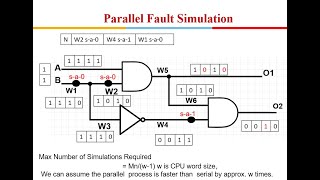

The high computational cost of simulations can limit the efficiency and feasibility of fault modeling in complex systems. Engineers must often find ways to optimize simulations or run them in parallel to mitigate these challenges.

Detailed

High Computational Cost

The section discusses the significant computational costs associated with running simulations on large systems in the domain of fault modeling and simulation. When engineers employ simulation tools to analyze the behavior of electronic systems under fault conditions, the complexity of these systems can lead to extensive processing times. As technology progresses and systems either scale in size or become more intricate, managing computational expenses becomes critical.

Key Points:

- Impact on Efficiency: High computational cost can severely impact the efficiency with which engineers can perform their fault simulations.

- Optimization Techniques: To counteract these costs, engineers may employ various optimization techniques or run simulations in parallel. This approach allows for quicker analysis while still maintaining accurate results.

- Trade-offs: Although these strategies may alleviate some burden, they also present trade-offs in terms of completeness and accuracy.

Understanding the implications of high computational costs is vital for engineers engaged in creating reliable electronic systems.

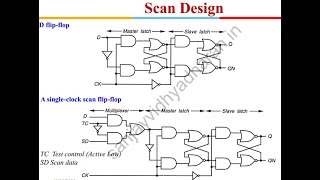

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Introduction to Computational Cost

Chapter 1 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Running simulations, especially on large systems, can be computationally expensive and time-consuming.

Detailed Explanation

When we talk about the computational cost of running simulations, we refer to the amount of computing power and time required to execute these simulations. Larger systems or designs require more complex calculations, which need more processing resources, leading to increased costs and time spent. Essentially, more complexity equals more computational demands.

Examples & Analogies

Think of it like assembling a large puzzle. A simple 100-piece puzzle can be completed quickly, while a 10,000-piece puzzle will take much longer and require more effort to put together. Just like that, running simulations on simpler systems is quick, whereas complex systems require significantly more resources to analyze.

Optimization Techniques

Chapter 2 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

In some cases, simulations may need to be optimized or run in parallel to reduce processing time.

Detailed Explanation

To address the issue of high computational costs, engineers may employ optimization techniques. These techniques include improving the algorithms used in simulations to make them more efficient and running simulations in parallel, which means breaking the simulation into smaller parts that can be processed at the same time by different processors or computers. This parallelization reduces the total time taken to run complex simulations.

Examples & Analogies

Imagine you're baking cookies. If you bake one tray of cookies at a time, it might take a lot longer compared to if you use multiple ovens to bake several trays simultaneously. Likewise, by running simulations in parallel, we can finish larger tasks in a fraction of the time.

Key Concepts

-

High computational costs must be managed efficiently to enable effective fault simulations.

-

Optimization can lead to trade-offs between speed and accuracy.

-

Industries such as aerospace and automotive are particularly affected by the need to balance computational costs.

Examples & Applications

A large-scale electronic design may require multiple hours of computational time to simulate, highlighting the importance of optimizing these processes.

In aerospace, simulations that optimize flight patterns must be accurate and efficient to avoid potential safety issues.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

To simulate well, keep costs in sight, / Optimize your run, so things are right.

Stories

Imagine a team of engineers racing against time. They must test their new electronic designs but find that their simulations take forever! By prioritizing key simulations and running them in pairs, they find success and early designs mean less rework.

Memory Tools

Remember the acronym C.O.P. - Computational cost, Optimization strategies, and Parallel processing.

Acronyms

C.O.P. (Computational cost, Optimization strategies, Parallel processing)

Flash Cards

Glossary

- Computational Cost

The amount of computational resources (time, power) required to run simulations.

- Optimization

Techniques used to improve the efficiency and speed of simulations.

- Parallel Processing

Running multiple simulations concurrently to decrease overall processing time.

Reference links

Supplementary resources to enhance your learning experience.