Key Properties of Etching

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Selectivity in Etching

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's start with the first property of etching: selectivity. Selectivity is essential because it allows us to etch away unwanted material while preserving layers that we want to keep intact.

Can you give us an example of where selectivity is important?

Absolutely! For instance, in a multi-layer structure where you have silicon on top of a metal layer, selective etching ensures that we can remove the silicon without damaging the underlying metal. Think of it as a delicate dance where each material knows to stay in its lane!

How do manufacturers control selectivity?

Selectivity can be achieved by choosing the right etchant, adjusting the process conditions, or even changing the geometry of the features being etched to better differentiate between materials.

So selectivity is about making sure we achieve the right results without harming other layers?

Exactly! Selectivity is a crucial factor in maintaining the integrity of device structures.

What acronym could help us remember selectivity?

You can use 'SAFE' - S for specific material, A for avoided layers, F for feature integrity, and E for etching precision!

In summary, selectivity is vital for ensuring we can etch precisely without damaging other materials.

Anisotropy in Etching

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's move on to anisotropy. Anisotropic etching allows for controlled removal of material in a specific direction. Why do you think this is important?

I guess it's so we can achieve vertical profiles rather than just uneven shapes?

Exactly! Vertical profiles are essential for modern semiconductor devices where space is at a premium. This control allows complex 3D structures to be created.

How can we achieve anisotropic etching?

Anisotropic etching is often accomplished through dry etching techniques, like Reactive Ion Etching (RIE), which directs ions towards the surface to achieve the desired profile.

Can you remind us why vertical profiles are beneficial?

Vertical profiles help in maximizing space efficiency on chips and are crucial for maintaining the electrical properties of devices.

What's a memory aid we can use for anisotropy?

You can remember it with 'ANISOTROPY = A New Innovative Shape On a Top-Right Plane Yonder,' emphasizing the directionality of the etching process!

To summarize, anisotropy is critical for creating defined structures, helping us manage space and performance.

Etch Rate Control

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, we’ll discuss etch rate control. Why is controlling the etch rate important in semiconductor manufacturing?

If we don’t control it, we might remove too much material, right?

Exactly! Controlling the etch rate is vital for maintaining the precision of the critical dimensions we need in circuit patterns.

How do you measure and control the etch rate?

Etch rates can be influenced by factors like temperature, pressure, and gas composition in dry etching techniques. Engineers often use real-time monitoring systems to assess and adjust these variables.

What happens if the etch rate is too high or too low?

Too high can lead to undesired undercutting, while too low can result in incomplete etching, both of which negatively affect device performance.

Is there a simple memory aid for this?

Sure! You can remember it with the saying 'Easy Does It' - emphasizing that adjusting and controlling the etch rate requires careful management to ensure precision.

In conclusion, effective etch rate control is crucial for achieving high-quality, dimensional accuracy in semiconductor manufacturing.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section discusses key properties of etching, including selectivity, anisotropy, and etch rate control. Understanding these properties is essential for achieving accurate patterns and maintaining the integrity of materials during the etching process.

Detailed

Key Properties of Etching

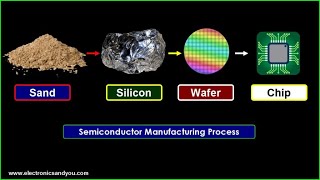

Etching is a fundamental technique in semiconductor manufacturing, enabling the formation of intricate patterns on semiconductor wafers. It is essential for producing high-precision features necessary in integrated circuits. In this section, we delve into the key properties of etching that ensure its effectiveness and efficiency in semiconductor processes.

Key Properties:

- Selectivity:

- This property refers to the ability of the etching process to remove a specific material without adversely affecting others. High selectivity is crucial in multilayer structures where retaining certain materials while removing others is necessary.

- Anisotropy:

- Anisotropic etching allows for controlled removal of materials in a specific direction, which is vital for creating vertical profiles. This property ensures the etching is not uniform in all directions, leading to defined and precise feature shaping.

- Etch Rate Control:

- This involves the regulation of the speed at which materials are removed. Accurate etch rate control is important for maintaining critical dimensions, particularly as feature sizes decrease in advanced technology nodes.

These properties are interrelated and collectively impact the quality and reliability of semiconductor manufacturing, guiding engineers in the design and execution of effective etching strategies.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Selectivity

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

● Selectivity: Ability to remove one material without affecting others.

Detailed Explanation

Selectivity refers to the capability of etching processes to remove specific materials while leaving others intact. This precision is crucial when creating intricate patterns on semiconductor wafers. For instance, if a layer of silicon dioxide is present on top of silicon, the etching process should only remove the silicon dioxide and not etch into the silicon beneath it. This selective removal ensures the functionality of the integrated circuit remains intact as only the intended materials are altered.

Examples & Analogies

Imagine a sculptor chiseling away at a block of marble to create a statue. If the sculptor can accurately remove the excess marble without damaging the desired parts of the statue, that is akin to high selectivity in etching.

Anisotropy

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

● Anisotropy: Directional etching, important for vertical profiles.

Detailed Explanation

Anisotropy describes the directionality of the etching process, which is vital for producing vertical features in semiconductor devices. Unlike isotropic etching, which removes material uniformly in all directions (leading to rounded corners or sloped profiles), anisotropic etching targets specific directions. This is particularly important for creating sharp, defined edges and features that require vertical profiles, such as the sidewalls of small features in modern transistors.

Examples & Analogies

Think of a mason cutting a stone. If they cut straight down to create a wall, that’s similar to anisotropic etching. However, if they accidentally carve away all around, not maintaining straight edges but rather rounding the corners, that's like what happens in isotropic etching.

Etch Rate Control

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

● Etch Rate Control: Vital for critical dimension accuracy.

Detailed Explanation

Etch rate control is the ability to regulate how quickly material is removed during the etching process. This control is essential for achieving the precise dimensions required in semiconductor manufacturing, known as critical dimensions (CD). If the etching rate is too fast, it might remove too much material, leading to features that are smaller than intended. Conversely, a slow rate might result in incomplete etching. By precisely adjusting process parameters like time, power, and gas flow, engineers can achieve the desired etch rates.

Examples & Analogies

Consider painting a fence: if you use too much paint too quickly, it can run and create a messy appearance, while applying paint too slowly can lead to uneven coverage. Similarly, controlling the etch rate ensures that the material is removed precisely to maintain the intended design.

Key Concepts

-

Selectivity: The property that dictates which materials can be etched without affecting others.

-

Anisotropy: A principle that allows for directional etching to create vertical features.

-

Etch Rate Control: A critical factor to ensure precise material removal without excess degradation.

Examples & Applications

In IC manufacturing, using a specific etchant to selectively remove silicon without affecting aluminum layers underneath.

Utilizing RIE for creating vertical sidewalls in etching patterns that are essential for high-density circuits.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

To etch with care, let it be fair; select your targets, beware and beware!

Stories

Imagine a sculptor using a chisel to carve a statue. Through careful selection and control, they only remove pieces of stone without damaging the intricate details around it.

Memory Tools

Remember 'SANE' for Selectivity, Anisotropy, and New Etching techniques.

Acronyms

ESM

Etch Selectivity Matters.

Flash Cards

Glossary

- Selectivity

The ability to etch or remove a specific material without affecting other materials.

- Anisotropy

Refers to the directional dependence of the etching process, allowing for vertical profiles in features.

- Etch Rate

The speed at which material is removed during the etching process, critical for maintaining feature size.

Reference links

Supplementary resources to enhance your learning experience.