Step 2: Etching Equipment Overview

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Etching Equipment

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we are exploring different types of etching equipment. Can anyone give me a brief description of what etching equipment does?

I think etching equipment removes material from the wafer to create patterns.

Exactly! Etching is a process used to define specific patterns on the wafer. Let's talk about the RIE system first. RIE stands for Reactive Ion Etching. Student_2, can you tell us what makes RIE unique?

RIE uses ion bombardment, right? That means it can achieve more precise etching profiles.

Correct! This precision is crucial for creating fine features on the semiconductor. Now, Student_3, what about ICP etchers?

They have higher plasma density, and I think they can etch deeper.

Right again! Higher plasma density allows for faster etching rates. And lastly, what do ashers do? Student_4?

Ashers remove the photoresist after etching, right?

Yes! Removing photoresist is essential for maintaining surface cleanliness. Let's summarize: RIE is for precision, ICP etchers offer deeper etches, and ashers clear the residue.

Understanding Wet Benches and Their Role

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

We've covered RIE, ICP, and ashers. Now, let's discuss wet benches. Who can explain their purpose and how they differ from dry etching equipment?

Wet benches use chemicals for isotropic etching, so they can remove material uniformly over larger areas.

Great point! Isotropic etching means the material is removed equally in all directions. This is useful when a uniform profile is required. Student_2, why might someone choose a wet bench over RIE?

Maybe for simpler applications or larger surfaces that don't need precise profiles?

Exactly! Remember, the choice of equipment depends on the specific etching requirements. To recap, wet benches are ideal for uniform material removal, while dry etching methods like RIE provide more definition.

Components of Plasma Etching Systems

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s look at a plasma etching system schematic. Can anyone tell me the significance of the vacuum chamber in this setup?

It keeps the process controlled, preventing contamination.

Exactly! Maintaining a vacuum is crucial for precision. what about RF-powered electrodes, Student_4?

They generate plasma, right?

That's correct! Plasma provides the energy needed for the etching reactions. Let's not forget about gas inlets. Student_1, why are they needed?

They deliver the etchant gases necessary for the chemical reactions, right?

Absolutely! An efficient gas delivery is key to a successful etching process. Finally, we have the exhaust system to remove byproducts. Does anyone want to summarize the main components?

We have the vacuum chamber, RF electrodes, gas inlets, wafer chuck, and exhaust system.

Correct! Good job summarizing the components of a plasma etching system.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

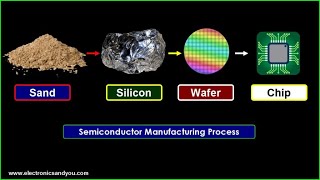

The etching equipment overview highlights several key types of etching systems used in semiconductor fabrication. Each system serves distinct functions, such as directional dry etching with RIE, deeper etches with ICP, and removing photoresist with ashers. Additionally, it introduces the necessary components and schematic of a plasma etching system.

Detailed

Etching Equipment Overview

In semiconductor fabrication, various types of etching equipment play crucial roles in achieving desired material removal and patterning. In this section, we outline several key equipment types:

Equipment Types and Functions

- RIE System: Enables directional dry etching, utilizing ion bombardment to achieve precise etching profiles.

- ICP Etcher: Offers higher plasma density, allowing for deeper etches while improving etching speed and consistency.

- Ashers: Specifically designed to remove photoresist layers post-etch, ensuring the cleanliness of the surface for subsequent processes.

- Wet Bench: Utilized for isotropic etching using chemical tanks, suitable for specific applications that require uniform material removal across wider surfaces.

Plasma Etching System Schematic

Understanding the layout of a plasma etching system is essential:

- Vacuum Chamber: Provides a controlled environment for the etching process.

- RF-Powered Electrodes: Generate the plasma necessary for chemical reactions.

- Gas Inlets: Deliver etchant gases into the chamber for etching reactions.

- Wafer Chuck: Holds the wafer in place during etching.

- Exhaust System: Ensures the removal of byproducts and maintains necessary pressure conditions.

Significance

By recognizing the various etching systems and their functions, one can appreciate the intricate nature of semiconductor manufacturing processes. Proper equipment selection is vital for achieving the high precision and efficiency required in modern nanotechnology.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Overview of Etching Equipment

Chapter 1 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Equipment Type Function

RIE System Directional dry etching with ion bombardment

ICP Etcher Higher plasma density, deeper etches

Ashers Remove photoresist after etch

Wet Bench Chemical tanks for isotropic etching

Detailed Explanation

In semiconductor manufacturing, various types of equipment are used for etching processes. Here’s a breakdown:

- RIE System: This system uses directional dry etching, which means it removes material from the wafer surface using charged ions. It allows for high precision in creating patterns.

- ICP Etcher: Inductively Coupled Plasma (ICP) etchers produce a higher density plasma, which enables deeper etching into materials. This is particularly useful for structures that require a significant amount of material to be removed.

- Ashers: After etching, a photoresist layer, which is used to create patterns, needs to be removed. Ashers are chemical devices that efficiently eliminate this layer without damaging the underlying material.

- Wet Bench: This is a chemical tank that facilitates isotropic etching, which removes material evenly from all sides, unlike the directional approach of RIE systems.

Examples & Analogies

Think of etching equipment like tools in a workshop. Just as a woodworker uses a saw for cutting straight lines and a chisel for detailed carving, semiconductor manufacturers use different equipment for various types of etching. The RIE system is like a precision saw for sharp, clear cuts, while the ICP etcher is like a powerful drill for deeper holes. Ashers are like cleaning tools that tidy up after the job, and wet benches are akin to gentle sanders that smooth out surfaces.

Plasma Etching System Schematic

Chapter 2 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Plasma Etching System Schematic:

• Vacuum chamber

• RF-powered electrodes

• Gas inlets (etchant gases)

• Wafer chuck

• Exhaust system

The tool maintains uniformity, pressure, temperature, and plasma intensity to ensure repeatable etch results.

Detailed Explanation

The plasma etching system consists of several key components that work together to achieve effective etching:

- Vacuum Chamber: This enclosure keeps the environment controlled, which is necessary for the etching process to work correctly. The vacuum helps prevent contamination and ensures that the gases can react effectively.

- RF-Powered Electrodes: These electrodes generate the high-frequency power needed to create plasma. Plasma is a state of matter where gases are ionized and can conduct electricity, crucial for the etching process.

- Gas Inlets: These are the entry points for etchant gases, which are specifically formulated to react with different materials being etched on the wafer.

- Wafer Chuck: This is the holder for the wafer, ensuring it remains stable and in the correct position during the etching process.

- Exhaust System: This system removes excess gases and by-products created during etching, maintaining a clean operational environment.

Together, these components ensure that the etching process is uniform and reliable, which is essential for producing high-quality semiconductor devices.

Examples & Analogies

Imagine a high-tech kitchen where a chef prepares a complicated dish. The vacuum chamber is like a sterilized kitchen to prevent any contamination. RF-powered electrodes serve as the stovetop and oven that provide the necessary heat to cook ingredients. The gas inlets are like spice dispensers where the chef adds unique flavors. The wafer chuck is the cutting board that holds everything in place, while the exhaust system acts like a ventilation hood, removing smoke and odors to keep the cooking area fresh.

Key Concepts

-

RIE System: Utilizes ion bombardment for directional etching, essential for precise patterns.

-

ICP Etcher: Achieves deeper etches with higher plasma density for efficient processing.

-

Ashers: Removing photoresist is crucial for surface preparation after etching.

-

Wet Bench: Provides isotropic etching, commonly used for broader applications.

-

Plasma Systems: Constitute various components like vacuum chambers and RF electrodes for effective operations.

Examples & Applications

A RIE system is often used when etching patterns for advanced microprocessors that require intricate designs.

Wet benches are commonly utilized in laboratories for educational purposes to teach students about isotropic etching processes.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

In etching we clean, remove and define, with tools like asher and benches that shine.

Stories

Once there was a small workshop where each etching tool worked merrily. The RIE system etched with precision, while the asher cleaned up, making sure the place sparkled like new.

Memory Tools

Remember RIA WACE: RIE, ICP asher, Wet bench, and Control Environment for etching!

Acronyms

E-WIPE

Etching- Wet bench

ICP

Photoresist removal

Equipment.

Flash Cards

Glossary

- RIE System

Reactive Ion Etching system that uses ion bombardment for directional dry etching.

- ICP Etcher

Inductively Coupled Plasma etching equipment that allows for deeper etching with higher plasma density.

- Ashers

Tools specifically designed to remove photoresist layers after the etching process.

- Wet Bench

Chemical tanks used for isotropic etching in semiconductor processes.

- Vacuum Chamber

A sealed environment used in etching processes to maintain controlled conditions.

- RFpowered Electrodes

Electrodes that generate plasma by radio frequency power in etching systems.

- Wafer Chuck

A device that holds the wafer in place during the etching process.

- Exhaust System

System to remove byproducts and maintain pressure in etching systems.

Reference links

Supplementary resources to enhance your learning experience.