Doping Techniques in Compound Semiconductors

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Doping During Growth

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's discuss the doping techniques used during the growth of compound semiconductors. In MOCVD, we use dopants like silane and diethylzinc. Can anyone tell me why it's beneficial to add dopants during the growth process?

I think it allows for better control of the doping concentration.

Exactly! This control enables us to optimize the electrical properties of the material for specific applications. Now, what about MBE? Any thoughts?

Isn’t it that MBE uses separate elemental sources for doping, which gives it a different advantage?

Yes, well done! MBE allows for precise adjustments to the doping profile by using elemental sources like Silicon or Beryllium. Remember this acronym: DPR - Doping Precision in Research.

Ion Implantation

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, let's move on to ion implantation. What can you tell me about how this technique works?

Dopant ions are accelerated and implanted into the semiconductor material, right?

Correct! It allows for very precise doping concentrations, but what’s a notable downside?

It can damage the crystal structure, right? So, we need to do annealing after implantation to fix it?

Excellent! Yes, the post-implant annealing is crucial to activate the implanted dopants and heal any damage. Keep in mind the mnemonic DPDA - Damage Prevention through Doping Annealing for this step.

Diffusion Doping

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let's touch upon diffusion doping. Why do you think it's less common in compound semiconductors?

Because the diffusivity of dopants is low?

Exactly! Since diffusion is inefficient for many dopants used in compound semiconductors, it limits its usefulness. Can anyone think of the implications of this?

It makes the other methods, like MOCVD and MBE, more favorable for precise doping control.

That's correct! Remember the acronym LDD - Low Diffusivity Doping, to recall why diffusion isn't widely used. In conclusion, MOCVD and MBE are the preferred methods due to their precision and effectiveness.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Doping techniques in compound semiconductors are essential for tailoring the electrical properties of materials. This section covers doping during growth with MOCVD and MBE methods, as well as less common techniques like ion implantation, highlighting their advantages and limitations.

Detailed

Doping Techniques in Compound Semiconductors

Doping is a critical process in the fabrication of compound semiconductors, as it allows for the adjustment of electrical properties to meet specific device requirements. Three primary methods are highlighted:

1. Doping During Growth

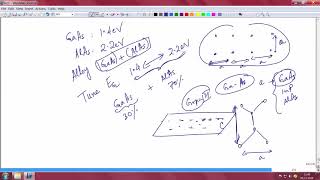

- MOCVD (Metal-Organic Chemical Vapor Deposition): Here, dopants such as silane (SiH₄) and diethylzinc (DEZn) are introduced during the growth process, enabling excellent control over the doping concentration.

- MBE (Molecular Beam Epitaxy): In this technique, doping is achieved using separate elemental sources (e.g., Si or Be) to accurately control the doping profile.

2. Ion Implantation

- Ion implantation is a method where ions of the dopant are accelerated and implanted into the semiconductor material. Although this technique is effective for achieving precise doping concentrations, it has the disadvantage of potentially damaging the crystal structure, necessitating a post-implant annealing step for activation.

3. Diffusion

- Diffusion doping is rarely used in compound semiconductors due to the low diffusivity of many dopants, making it less effective compared to the first two methods.

Overall, understanding these doping techniques is vital for optimizing the performance of semiconductor devices.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Doping During Growth

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- During Growth:

- MOCVD: Dopants like silane (SiH₄), diethylzinc (DEZn)

- MBE: Doped using separate elemental sources (e.g., Si, Be)

Detailed Explanation

Doping during the growth of compound semiconductors is crucial as it determines the electrical properties of the semiconductor. In Metal-Organic Chemical Vapor Deposition (MOCVD), dopants such as silane (SiH₄) and diethylzinc (DEZn) are introduced directly into the growth environment. This incorporation allows for precise control over doping levels. On the other hand, in Molecular Beam Epitaxy (MBE), dopants are added using separate elemental sources, which allows for very fine-tuning of the doping profile. This is important to create different types of semiconductors—n-type or p-type—depending on the type of dopant used.

Examples & Analogies

Think of doping like adding spices to food. Just as certain spices can enhance the flavor of a dish, doping materials can enhance the electrical properties of semiconductors. Different dishes (or semiconductor types) require different spices (or dopants) to achieve the desired taste (or electronic properties). For instance, using silane (like adding salt) may enhance conductivity, while diethylzinc (like adding sugar) could make a compound more suitable for specific applications.

Ion Implantation

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Ion Implantation:

- Less common due to crystal damage

- Post-implant annealing needed for activation

Detailed Explanation

Ion implantation is a technique where ions of a dopant are accelerated and then implanted into a semiconductor material. While effective for adding impurities, this method is less common in compound semiconductors due to the potential for crystal damage during the implantation process. To mitigate this damage, a subsequent process called post-implant annealing is necessary. This involves heating the material to allow the implanted ions to settle into the crystal lattice properly, thus activating the dopants and repairing any damage.

Examples & Analogies

Imagine planting seeds in a garden. If you just throw the seeds on the surface, they might not take root effectively (like ion implantation leading to damage). To help them grow, you need to cover them with soil and water them (post-implant annealing) to ensure they settle in properly and thrive. In semiconductor fabrication, this step is crucial for achieving the right properties.

Diffusion

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Diffusion:

- Rare in compound semiconductors due to low diffusivity

Detailed Explanation

Diffusion is a process where dopants move within the semiconductor material to achieve a uniform concentration. However, in the case of compound semiconductors, diffusion is rarely used. This is because these materials generally have low diffusivity, which means that the dopants do not move easily through the semiconductor. As a result, alternative doping techniques such as MOCVD and MBE are preferred for introducing impurities effectively.

Examples & Analogies

Think of diffusion like how food coloring spreads in water. In a glass of warm water, food coloring spreads quickly and mixes well. However, if the water is cold (representing the low diffusivity in compound semiconductors), the coloring will barely move. Just like we seek efficient ways to mix colors, in semiconductor fabrication, we need more effective methods (like MOCVD or MBE) for doping rather than relying on diffusion.

Key Concepts

-

Dopping Techniques: Methods used to introduce dopants into semiconductor materials.

-

MOCVD: A technique allowing the integration of dopants during the growth of semiconductor layers.

-

MBE: A precise technique that uses elemental sources for doping.

-

Ion Implantation: A method to adjust doping concentration but requires post-annealing.

-

Diffusion: Rarely used due to low efficiency in compound semiconductors.

Examples & Applications

Using silane (SiH₄) in MOCVD to create n-type material in GaAs.

Employing Be as a dopant in MBE to achieve p-type conductivity.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

When you want to add a little spice, MOCVD first sounds so nice!

Stories

Imagine a lab where scientists play with different elements, creating the perfect semiconductor by carefully adding elements like beads into a string—each bead represents a dopant added during MOCVD or MBE.

Memory Tools

Remember DPDA for Ion Implantation – Damage Prevention through Doping Annealing!

Acronyms

Use LDD for Low Diffusivity Doping to remember why diffusion is not preferred.

Flash Cards

Glossary

- Doping

The process of intentionally introducing impurities into a semiconductor to change its electrical properties.

- MOCVD

Metal-Organic Chemical Vapor Deposition, a method for growing thin films using metal-organic precursors.

- MBE

Molecular Beam Epitaxy, a method for growing thin films by evaporating elemental sources in a vacuum.

- Ion Implantation

A technique that involves bombarding a semiconductor with energetic ions of the dopants.

- Diffusion

A process of introducing impurities into a semiconductor by allowing them to spread in the material.

Reference links

Supplementary resources to enhance your learning experience.