Emerging Techniques

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

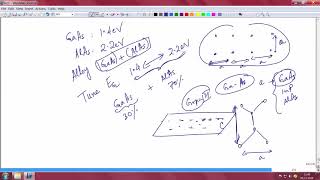

Selective Area Growth (SAG)

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're exploring Selective Area Growth, or SAG. This technique allows us to grow semiconductors only in designated areas of the substrate. Can anyone tell me why this might be beneficial?

It means we can be more efficient with the materials we use.

Exactly! By focusing the growth, we reduce waste and can optimize each layer’s composition for better performance. Remember the acronym 'SAG'—it stands for 'Selective Area Growth.'

Are there any real-world applications for SAG?

Great question! SAG can be used in laser diodes or integrated circuits where precision is vital. Let’s focus on localizing growth to enhance device performance.

Is it difficult to implement SAG?

It does require advanced techniques to mask areas and control growth conditions, but the benefits often outweigh these challenges. At the end of the day, precision is key! Let's summarize: SAG provides material efficiency and tailored growth areas.

Epitaxial Lift-Off (ELO)

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, let's discuss Epitaxial Lift-Off, or ELO. Does anyone know how this process works?

Isn't it about transferring layers to new substrates?

Exactly right! ELO allows us to lift thin layers from one substrate and transfer them to another, which helps in recycling substrates and lowering costs. This is particularly valuable in high-tech applications.

What kind of materials can be used for ELO?

Commonly, it involves III-V materials, as they have unique properties that benefit from this transfer. Always remember, ELO is about cost-effectiveness and material recovery.

So how does ELO affect the performance of devices?

By optimizing layer transfer, we can enhance device performance. As we sum up ELO, focus on its cost efficiency and recovery process for substrates.

Wafer Bonding

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Lastly, let's look at Wafer Bonding. This technique is crucial for integrating III-V devices with silicon electronics. What are the advantages of combining these technologies?

It allows for better functionality in electronics by leveraging both materials' properties.

Absolutely! Wafer bonding enables designers to harness the best attributes of each material, achieving higher efficiency and performance. Remember, we’re bridging gaps between different technologies.

What kind of devices benefit from this integration?

Many modern devices, like those in telecommunications and photonics, utilize this method. It results in enhanced functionalities. To wrap it up, Wafer Bonding is key to bridging III-V and silicon technologies.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section discusses novel methods like Selective Area Growth (SAG), Epitaxial Lift-Off (ELO), and Wafer Bonding that enhance the capabilities and applications of compound semiconductor fabrication, particularly in integrating with silicon technologies.

Detailed

Emerging Techniques

The field of compound semiconductor fabrication is advancing rapidly with new techniques aimed at optimizing layer growth and integration with existing technologies. This section introduces three critical emerging techniques:

- Selective Area Growth (SAG) enables localized epitaxial growth by allowing specific regions of the substrate to be activated for growth, which can improve material efficiency and device performance.

- Epitaxial Lift-Off (ELO) is a technique where thin epitaxial layers are transferred from their original substrate to another substrate, facilitating the recovery of substrates and reducing costs.

- Wafer Bonding is significant for heterogeneous integration, enabling the combination of III-V devices with silicon electronics, potentially leading to enhanced performance in various applications.

These techniques represent an evolution in the fabrication landscape, addressing challenges associated with traditional methods and opening new frontiers in semiconductor applications.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Selective Area Growth (SAG)

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

● Selective Area Growth (SAG): Enables localized epitaxial growth

Detailed Explanation

Selective Area Growth (SAG) is a technique that allows the growth of materials only in specific regions of a substrate. This targeted approach helps in creating defined structures on a semiconductor chip without affecting the entire surface. SAG is particularly useful when precise control over where different layers are deposited is required, enhancing device performance and integration capability.

Examples & Analogies

Imagine SAG like a painter who only wants to paint certain sections of a large wall mural without covering the entire wall. Just as the painter uses tape to block off areas they don’t want to paint, SAG uses masks to prevent growth in unwanted areas, focusing effort only where it’s needed.

Epitaxial Lift-Off (ELO)

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

● Epitaxial Lift-Off (ELO): Thin epitaxial layers are transferred to alternate substrates

Detailed Explanation

Epitaxial Lift-Off (ELO) is a technique where a thin layer of material grown on a substrate can be separated and transferred to another substrate. This is typically done by using a release layer that allows the thin layers to be peeled off gently. ELO is beneficial for creating devices that need to be integrated onto different materials, such as silicon, which enhances versatility in chip design.

Examples & Analogies

Think of ELO as peeling a layer of paint off a wall. If you meticulously apply paint and then carefully peel off a section, you could place that section on another wall. Similarly, ELO allows scientists to remove a thin layer of semiconductor and place it on another material, enabling new functionalities.

Wafer Bonding

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

● Wafer Bonding: For heterogeneous integration of III-V devices with silicon electronics

Detailed Explanation

Wafer Bonding is a technology that allows two distinct wafers—often one made of silicon and another made of III-V compound semiconductors—to be joined together. This heterogeneous integration combines the advantageous properties of both materials, which can lead to enhanced performance in electronic devices, particularly in applications needing high efficiency such as power circuits and photonic devices.

Examples & Analogies

Consider wafer bonding like gluing together two pieces of different puzzles that fit perfectly. Each piece has distinct features and purposes, but by bonding them, you create a larger, more functional picture that leverages the strengths of both pieces.

Key Concepts

-

Selective Area Growth (SAG): A technique for localized growth, improving material usage.

-

Epitaxial Lift-Off (ELO): A process for transferring layers, enhancing recovery.

-

Wafer Bonding: Integrates materials to combine their useful properties for better device performance.

Examples & Applications

Selective Area Growth is utilized in the fabrication of advanced laser diodes, ensuring material use is concentrated on active regions.

Epitaxial Lift-Off enables the recycling of expensive III-V substrates, lowering overall costs in high-end semiconductor applications.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

SAG lets growth be smart and precise, minimizing waste, is oh so nice!

Stories

Imagine a sculptor who can only chisel away block by block; with SAG, they only carve what they need, saving both time and effort.

Memory Tools

For ELO, think of 'Lift Op'—like lifting a pizza off a tray to place it on a plate.

Acronyms

ELO means Epitaxial Lift-Off—think of it as transferring layers expertly, like lifting a delicate piece of art.

Flash Cards

Glossary

- Selective Area Growth (SAG)

A technique allowing localized epitaxial growth by activating specific regions of the substrate.

- Epitaxial LiftOff (ELO)

A process that transfers thin epitaxial layers from one substrate to another for improved material recovery.

- Wafer Bonding

A method of integrating different semiconductor materials to leverage their combined properties.

Reference links

Supplementary resources to enhance your learning experience.