LPE (Liquid Phase Epitaxy)

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to LPE

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we’ll explore Liquid Phase Epitaxy, or LPE. It's a technique for growing semiconductor layers. Can anyone tell me what they think LPE involves?

Is it related to liquid solutions like how crystals form in nature?

Exactly! In LPE, materials are deposited from a supersaturated solution in a liquid melt. It's somewhat like how icicles form on a cold day.

What are some materials that can be grown using LPE?

Good question! LPE is often used for materials like GaAs, primarily for basic optical devices. Now, let’s remember LPE by thinking: 'Liquid = Layers of Epitaxy.'

Applications of LPE

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

LPE is still used, but mainly for older devices. Can someone suggest a type of device where LPE might be relevant?

Maybe in lasers?

Exactly! LPE was used in older GaAs lasers. Even though it’s less common now, it’s important to study how these techniques shaped our optical technologies.

Are there any limitations with LPE?

Yes, LPE has poor precision and thickness control, which is why newer methods like MOCVD and MBE are preferred. Remembering it as 'Limited Precision Epitaxtic' can help!

Limitations of LPE

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now that we've gone over what LPE is, let’s talk about its limitations. Why do you think precision is important in semiconductor fabrication?

Precision matters for the device performance, right?

Exactly! Poor precision can lead to defects, which affects the device functionality. That's why more advanced techniques have taken over LPE in many applications.

Can you summarize those limitations for us?

Certainly! The main limitations are poor precision and control, leading to less efficient material growth compared to methods like MOCVD and MBE.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Liquid Phase Epitaxy (LPE) is a method of growing high-quality semiconductor layers from a liquid solution, typically involving challenges like precision control that have led to its decline in favor of more modern methods. Applications include optical devices and older GaAs lasers.

Detailed

LPE (Liquid Phase Epitaxy)

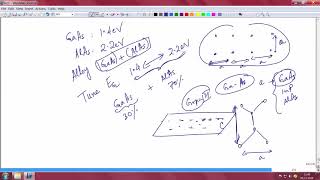

Liquid Phase Epitaxy (LPE) is a significant epitaxial growth technique used in semiconductor fabrication. This method grows material through a supersaturated solution in a liquid melt, resulting in the deposition of single crystals on suitable substrates. Although historically important, LPE has been outpaced by other techniques like MOCVD and MBE due to its limitations in precision and control.

Key Points:

- Working Principle: LPE involves the growth of semiconductor materials from a liquid melt that is supersaturated with the target material. By cooling the melt, crystals form as the concentration of dissolved material exceeds its solubility.

- Applications: Primarily used in the production of basic optical devices and an older generation of GaAs lasers. Its simplicity makes it attractive for specific applications despite its drawbacks.

- Limitations: The accuracy and precision of layer thickness control are poor compared to modern techniques, making LPE less favorable for developing advanced devices that require stringent specifications.

In summary, while LPE played an essential role in the history of semiconductor fabrication, its practical applications are now mainly limited to niches in the field of optoelectronics.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Working Principle of LPE

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Material is grown from a supersaturated solution in a liquid melt.

Detailed Explanation

Liquid Phase Epitaxy (LPE) involves growing a layer of material from a liquid solution that is supersaturated with the desired material. This means that the solution contains more of the material than it can stably hold at a given temperature, encouraging the material to deposit onto a substrate as it cools. The key here is controlling the temperature and concentration of the solution to ensure uniform growth.

Examples & Analogies

Imagine making a sugar solution. When you heat water and dissolve sugar, you can add more sugar than usual until it becomes saturated. If you cool this solution, sugar crystals start to form as the solution can't hold all the sugar anymore. In a similar way, LPE uses a saturated solution to promote layer growth on a substrate.

Applications of LPE

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Applications: Basic optical devices, older generation of GaAs lasers.

Detailed Explanation

LPE is primarily used in applications where precision is not as critical compared to modern techniques like MOCVD and MBE. This includes basic optical devices and older types of gallium arsenide (GaAs) lasers. These applications often do not demand the atomic-level precision required for more advanced optoelectronic devices, making LPE suitable for these older technologies.

Examples & Analogies

Think of LPE as the traditional way of baking a cake. It gets the job done for simple cakes, but if you're aiming to create a gourmet cake with intricate designs (like modern lasers), you might prefer more advanced baking techniques and tools.

Limitations of LPE

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Limitations: Poor precision, replaced by MOCVD/MBE in modern devices.

Detailed Explanation

The main drawbacks of LPE are its lack of precision and consistency compared to other methods. It struggles to control the thickness and composition of layers as accurately as MOCVD or MBE. Consequently, LPE has largely been superseded by these more advanced techniques in the production of modern electronic and optoelectronic devices.

Examples & Analogies

If you were to compare baking styles, LPE would be like using a simple home oven for regular baking, while MOCVD and MBE would be akin to using a high-tech, precision oven designed for gourmet pastries. The difference in quality and control is what makes the latter preferred for sophisticated recipes.

Key Concepts

-

LPE: A technique for growing layers from a liquid melt.

-

Supersaturation: The key process behind LPE, where a solution exceeds the solubility of the material.

-

Applications: Mainly in older optical devices and lasers.

-

Limitations: Poor precision makes LPE less favorable compared to MOCVD and MBE.

Examples & Applications

Using LPE to grow GaAs layers for laser devices.

The process of growing crystals similar to natural formations using LPE.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

LPE grows from a supersaturated pool, making crystals that are often quite cool.

Stories

Imagine a pot of hot soup. When we cool it down, bits of food rise up, forming nice little shapes just like LPE forming layers in semiconductors.

Memory Tools

LPE - 'Liquid Production Epitaxy' helps remember its process coming from a liquid state.

Acronyms

LPE = Layers from a Pool of Elements.

Flash Cards

Glossary

- Liquid Phase Epitaxy (LPE)

A semiconductor growth technique where materials are deposited from a supersaturated solution in a liquid melt.

- Supersaturated Solution

A solution that contains more solute than can be dissolved at a given temperature.

- GaAs

Gallium Arsenide, a compound semiconductor often used in optoelectronic devices.

- Epitaxy

The growth of a crystal layer on a crystalline substrate.

Reference links

Supplementary resources to enhance your learning experience.