MBE (Molecular Beam Epitaxy)

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to MBE

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we are going to discuss Molecular Beam Epitaxy, or MBE, which is a technique used to grow high-quality semiconductor films. Can anyone tell me why precision is crucial in semiconductor fabrication?

Precision is important because it affects the electronic and optical properties of the materials.

Exactly! MBE allows us to control material properties at the atomic level by evaporating elemental sources in a vacuum. Can anyone think of an example of materials that can be grown using MBE?

GaAs and InP are two examples!

Well done! MBE is particularly effective for those materials.

Process and Advantages of MBE

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s talk about the process of MBE. What happens during the epitaxy process?

The atoms evaporate from the sources and condense on the substrate, right?

Correct! This vacuum environment minimizes contamination and allows for atomic-level layering. Why do you think this is beneficial?

It allows for very sharp interfaces which can improve device performance.

Yes, precisely! Now, can anyone name a limitation of MBE?

I think it has a lower throughput compared to MOCVD?

Exactly, MBE is slower and more expensive, but its precision is worth it for critical applications.

Applications of MBE

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now that we understand the process and its advantages, let’s discuss applications. What devices could benefit from MBE technology?

I believe it’s used in laser diodes and high-speed transistors!

That's right! MBE is particularly effective for making components in optoelectronics. Can you think of why researchers might prefer MBE for these applications?

Because they need to tailor the materials' properties so precisely!

Excellent point! MBE allows for customizing the material properties needed for cutting-edge technology.

MBE vs. Other Techniques

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s compare MBE with MOCVD. Who can tell me one significant difference?

MBE operates under ultra-high vacuum while MOCVD uses gaseous precursors.

Exactly! MBE’s use of ultra-pure materials also helps in achieving higher quality films. What’s a consequence of the MBE’s lower throughput?

It could mean that it's less scalable for mass production?

Yes! This serves to highlight the trade-offs involved in choosing the right fabrication technique.

Summary and Key Takeaways

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

To wrap up, can someone summarize what we learned about MBE today?

We learned that MBE allows for atomic-level precision in semiconductor fabrication.

And it's ideal for applications where high-quality films are necessary, like lasers and high-frequency transistors.

Great summary! Remember, while MBE's precision is critical, its high cost and low throughput can limit its broader application.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

MBE is a vapor-phase epitaxy method where ultra-pure elemental sources are evaporated under ultra-high vacuum, condensing on a cooled substrate. This technique is notable for producing high-quality thin films with sharp interfaces, making it ideal for research and prototyping despite its lower throughput and complexity compared to other methods.

Detailed

Molecular Beam Epitaxy (MBE)

Molecular Beam Epitaxy (MBE) is a key fabrication technique for compound semiconductors characterized by its ability to achieve atomic-level precision in layer growth. In this process, ultra-pure elemental sources are evaporated in an ultra-high vacuum environment, allowing atoms to condense onto a substrate that has been cooled. This precise control enables the formation of high-quality epitaxial layers with abrupt interfaces, which are critical in semiconductor applications. Although the throughput of MBE is lower than that of other epitaxial techniques, such as MOCVD, it is particularly useful in research settings and for prototyping devices where quality and precision are paramount.

Key points of MBE include its applicability to various materials (e.g., GaAs, InP, AlGaAs) and its ability to grow structures with fine control over composition and thickness. The methodology, however, comes with limitations such as high operational costs and complex requirements for maintaining ultra-high vacuum conditions.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Working Principle of MBE

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

○ Ultra-pure elemental sources are evaporated under ultra-high vacuum (UHV).

○ Atoms condense on the cooled substrate to form epitaxial layers.

Detailed Explanation

Molecular Beam Epitaxy (MBE) is a technique that involves using ultra-pure sources of materials that are vaporized and then deposited onto a substrate in a vacuum. The ultra-high vacuum (UHV) environment is crucial because it prevents contamination that could affect the material layers being grown. As the atoms from the vaporized elemental sources hit the cooled substrate, they condense and form thin films in a highly controlled manner, allowing for precise layer creation.

Examples & Analogies

Think of MBE like making a delicate layer cake where each ingredient has to be added in just the right amount and at the right temperature to ensure it sets perfectly. If you add in too much flour or if the oven is too hot, the cake won’t turn out right. Similarly, in MBE, the purity of materials and the controlled environment ensure that the layers of atoms come together without any defects.

Materials Supported by MBE

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

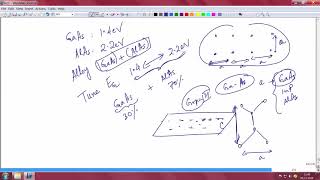

● Materials Supported: GaAs, InP, InGaAs, AlGaAs, HgCdTe

Detailed Explanation

MBE is capable of growing various compound semiconductors, which include Gallium Arsenide (GaAs), Indium Phosphide (InP), and several alloys like Indium Gallium Arsenide (InGaAs) and Aluminum Gallium Arsenide (AlGaAs). These materials are widely used in optoelectronic devices, including lasers and photodetectors.

Examples & Analogies

Imagine a chef who specializes in making several types of gourmet dishes. Each dish requires different ingredients and techniques. Similarly, MBE can be thought of as a specialized chef, adept at using different semiconductors to create high-performance electronic and photonic devices, selecting specific materials just like a chef chooses the right ingredients for each dish.

Advantages of MBE

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

● Advantages:

○ Atomic-level precision and abrupt interfaces

○ Excellent for research and prototyping

○ Lower growth temperature than MOCVD

Detailed Explanation

The advantages of MBE include its ability to achieve atomic-level precision, meaning that the number of atomic layers can be controlled very precisely. This is beneficial for creating sharp interfaces between different materials, which is crucial for high-performance devices. Additionally, MBE is particularly well-suited for research and development due to its flexibility in material options. Unlike some other methods, MBE can operate at lower temperatures, making it more adaptable to various materials.

Examples & Analogies

Consider a sculptor working with fine clay. The sculptor can make minute adjustments and create very detailed shapes. Similarly, MBE allows scientists and engineers to craft semiconductor layers with exceptional detail, producing devices that are highly efficient and tailored for specific tasks.

Limitations of MBE

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

● Limitations:

○ Low throughput

○ High cost and complexity

○ Requires ultra-high vacuum (~10⁻⁹ Torr)

Detailed Explanation

While MBE has many benefits, it also has its drawbacks. One major limitation is that it has a low throughput, meaning it can produce fewer layers in a given timeframe compared to other techniques like MOCVD. This low speed can increase production costs and overall complexity of the manufacturing process. Moreover, maintaining the ultra-high vacuum environment is costly and requires sophisticated equipment.

Examples & Analogies

Think of MBE like a high-end artisan bakery that takes a long time to make exquisite pastries. While the results are absolutely excellent, the bakery can only produce a limited number of pastries each day, and the process is expensive because of the quality of ingredients and specialized equipment used. In contrast, a fast-food restaurant can make many meals quickly, but the quality may not be as high.

Key Concepts

-

MBE Process: An epitaxy method where materials are evaporated in ultra-high vacuum.

-

Atomic-Level Control: Precision in layer thickness and composition that affects semiconductor properties.

-

Substrate: The base material on which epitaxial layers are grown.

Examples & Applications

MBE is used to fabricate quantum wells for high-speed electronic devices.

Researchers use MBE to create laser diodes with precise bandgap tailoring.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

MBE is the way, for layers so thin, atomic control wins, let the growth begin.

Stories

Imagine a chef in a restaurant where he can pick the finest ingredients quietly without disturbance, creating perfect dishes - this is how MBE operates, ensuring high purity while creating semiconductor layers.

Memory Tools

Remember: 'Molecular Beam Epitaxy' for precise layers - M.B.E. for Marvelous Beam Engineering.

Acronyms

MBE

Mastering Beam Epitaxy for precise semiconductor films.

Flash Cards

Glossary

- Molecular Beam Epitaxy (MBE)

A precision fabrication technique for growing high-quality semiconductor films with atomic-level control.

- UltraHigh Vacuum (UHV)

A vacuum level lower than 10⁻⁹ Torr, used in MBE to minimize contamination.

- Epitaxial Layer

A layer of material grown on a substrate in such a manner that its crystal structure is aligned with that of the substrate.

- Evaporation

The process of transforming a solid into vapor, allowing atoms to deposit onto a substrate.

Reference links

Supplementary resources to enhance your learning experience.