HVPE (Hydride Vapor Phase Epitaxy)

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to HVPE

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're diving into HVPE or Hydride Vapor Phase Epitaxy. Does anyone know what epitaxy means?

Isn't it about growing thin films on substrates?

Exactly! Epitaxy involves depositing material layer-by-layer on a substrate to create high-quality semiconductor films. HVPE specifically uses hydrogen halides for this process.

What kind of materials can be produced with HVPE?

Great question! HVPE mainly supports GaN, crucial for LEDs and high-power devices. Now, let's think about why this kind of growth is essential.

It's because it maintains good quality for the devices, right?

Absolutely! High-quality materials translate to better device performance. Let's move on to how this actually works. Any guesses on the reactions involved?

Does it involve chemical reactions?

Correct! Hydrogen halides react with metal sources to enable the growth. Remember this: 'halides help, so GaN can excel!' It can aid your understanding of HVPE's role.

To recap, HVPE is a key method for growing GaN substrates, essential in various optoelectronic applications.

Applications and Limitations of HVPE

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now that we've discussed how HVPE works, let's talk about its applications. What devices do you think benefit from HVPE?

I think LEDs, especially blue ones!

Absolutely! The capability to create high-quality GaN allows for efficient blue LEDs and high-power devices. However, there are limitations. What's one you might expect?

Is it the control of the composition of layers?

Spot on! HVPE is less precise in controlling thin film composition compared to techniques like MOCVD. This is a critical factor when designing advanced semiconductor devices. Remember: 'Thickness is key in HVPE, precision is a careful decree!'

So is HVPE mainly for substrates rather than active device layers?

Yes! While HVPE excels in substrate growth, other methods might be better for creating the active layers of devices. Effective combinations are essential in the industry.

In summary, HVPE is crucial for high-quality GaN substrates but has limitations in composition control.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section discusses Hydride Vapor Phase Epitaxy (HVPE) as an epitaxial growth method primarily for GaN substrates. It outlines its working principles, applications, advantages, and limitations, emphasizing HVPE's role in creating thick layers beneficial for LED and high-power device production.

Detailed

HVPE (Hydride Vapor Phase Epitaxy)

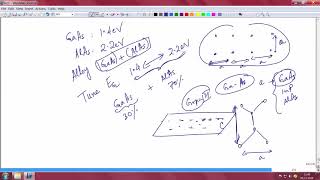

HVPE is a significant epitaxial growth technique employed in the production of compound semiconductors, particularly gallium nitride (GaN). This method utilizes reactions involving hydrogen halides, such as HCl, which react with metal sources to facilitate the growth of thick semiconductor layers. The key applications of HVPE include the production of high-quality GaN substrates, which are fundamental to the manufacturing of blue LEDs and high-power GaN devices.

Key Points:

- Working Principle: HVPE relies on the reaction of hydrogen halides with metal sources, enabling thick layer growth through chemical vapor processes.

- Materials Supported: Primarily used for GaN, HVPE is crucial in producing substrates that meet the demands of modern optoelectronic devices.

- Advantages: HVPE allows for the growth of substantial layers, leading to high-quality substrates suitable for electronic and photonic applications.

- Limitations: The method provides less control over the composition of thin films compared to other epitaxial techniques, limiting its application primarily to substrate production.

In conclusion, while HVPE has its limitations in thin film composition control, its advantages in producing high-quality substrates are pivotal for advancing GaN technologies.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Working Principle of HVPE

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Uses reactions of hydrogen halides (like HCl) with metal sources to grow thick layers.

Detailed Explanation

Hydride Vapor Phase Epitaxy (HVPE) is a process where hydrogen halides, such as hydrochloric acid (HCl), react with certain metal sources to facilitate the growth of semiconductor layers. The reaction typically results in the deposition of material onto a substrate, allowing for thick layers of semiconductors to be formed. This method is particularly effective for materials like Gallium Nitride (GaN).

Examples & Analogies

Think of HVPE like baking a multi-layer cake. Just as you layer batter in a cake pan to create more volume, HVPE builds up layers of semiconductor material layer by layer, creating a thicker structure that's used in electronic components.

Materials Supported by HVPE

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Materials Supported: GaN (bulk substrate growth).

Detailed Explanation

HVPE is specifically known for its ability to support the growth of Gallium Nitride (GaN) substrates. GaN is a key material in the production of high-performance electronic devices, particularly in applications such as blue LEDs and high-power devices. The use of HVPE allows for the creation of high-quality bulk crystals of GaN, which are essential for these applications.

Examples & Analogies

Imagine a construction worker using a powerful machine to create solid bricks from raw materials. Similarly, HVPE works as a tool for creating high-quality crystals of GaN, which serve as the 'bricks' for building advanced electronic devices.

Applications of HVPE

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Applications: High-quality GaN substrates for blue LEDs and high-power GaN devices.

Detailed Explanation

The main applications of HVPE include the production of high-quality GaN substrates, which are crucial for devices like blue light-emitting diodes (LEDs) and high-power GaN electronics. The capability to produce thick layers with minimal defects makes HVPE a preferred method in these high-tech industries. Blue LEDs are essential for modern lighting and display technology, while high-power devices are needed in sectors like power electronics and RF (radio frequency) applications.

Examples & Analogies

Consider HVPE like a specialized artist who creates intricate glass sculptures. Just as the artist ensures the glass pieces are flawless for the sculpture to shine, HVPE ensures the semiconductor layers are top-notch for the devices to perform effectively in lighting and power management.

Limitations of HVPE

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Limitations: Less control over thin film composition; Mostly used for substrate production.

Detailed Explanation

While HVPE is effective for producing thick substrates, it has some drawbacks. One significant limitation is the reduced control over the composition of very thin films compared to other techniques like MOCVD or MBE. This means HVPE is primarily utilized for substrate production rather than intricate layer applications, where precise composition is critical.

Examples & Analogies

Think of HVPE as a tool that excels in pouring concrete foundations for buildings. While it’s great at making solid bases (substrates), it might not be as good for the delicate finishing work—like placing fine tile or decorations—where precision is required. This highlights HVPE's strong suit and where its limitations lie.

Key Concepts

-

Hydride Vapor Phase Epitaxy: A method for growing semiconductor layers using hydrogen halides.

-

GaN: Primary material produced using HVPE, crucial for modern optoelectronic devices.

-

Growth Mechanism: Involves chemical reactions that facilitate thick layer deposition.

Examples & Applications

HVPE is used to produce the bulk GaN required for blue LEDs, which are essential in display technologies.

The method is also significant for high-power applications, where quality substrates are critical for device efficiency.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

In HVPE, the halides react, thick layers they create, it's a matter of fact!

Stories

Imagine a chemist in a lab mixing gases to grow GaN layers—like planting seeds, but with halides making sure everything grows thick and strong.

Memory Tools

Remember 'HVPE for Happy Vacuum Production of Epitaxial layers.'

Acronyms

HVPE

for Halides

for Vapor

for Phase

for Epitaxy—think about the process!

Flash Cards

Glossary

- Epitaxy

A method for growing semiconductor layers on a substrate in a specific crystalline orientation.

- GaN

Gallium Nitride, a compound semiconductor used in high-power and optoelectronic applications.

- Hydrogen Halides

Compounds formed from hydrogen and halogens, used as key reactants in HVPE.

- Substrate

The underlying layer on which epitaxial growth occurs.

Reference links

Supplementary resources to enhance your learning experience.