Fabrication Techniques for Compound Semiconductors

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Compound Semiconductor Fabrication

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Welcome class! Today, we'll explore how compound semiconductors are fabricated. Unlike silicon, these materials require precise control over atomic composition and crystal quality. Can anyone describe why that is important?

It's important because the electrical and optical properties are closely tied to these factors!

Exactly! That's why we often use epitaxial growth techniques. Remember the acronym 'E-GROW'—Epitaxial Growth Methods for our understanding of this. Now, does anyone know what the main epitaxial techniques are?

MOCVD and MBE!

Good job! We will discuss those in detail. But first, why can't we use traditional silicon methods fully here?

Because compound semiconductors have different material properties?

Exactly! They need specialized processes. Let's dive deeper into the epitaxial growth techniques.

Epitaxial Growth Techniques

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

We’ve established that MOCVD and MBE are crucial. Let's look at MOCVD first. Who can tell me how it works?

It uses metal-organic precursors that decompose at high temperatures.

Great! And what are the pros and cons of using MOCVD?

Advantages include high throughput and precise control. But it also requires high temperatures and toxic gases.

Exactly! Now, how does MBE compare to MOCVD?

MBE offers atomic-level precision with lower temperatures but has a lower throughput and is more expensive!

Correct! Both techniques have roles depending on the application. Now let’s discuss substrate selection.

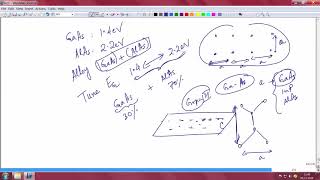

Substrate Selection and Lattice Matching

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Substrate selection is crucial for minimizing lattice mismatch. Why do you think this is important?

Lattice mismatch can cause dislocations and defects in the material.

Correct! Buffer layers and graded layers are methods to alleviate these stresses. Can anyone list common substrates?

GaAs, InP, SiC, and Sapphire are some examples.

Excellent! Each has its unique applications. Let's summarize these key points.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The chapter outlines critical fabrication processes for compound semiconductors, focusing on epitaxial growth techniques such as MOCVD, MBE, and others, while explaining challenges, substrate selection, and doping methods essential for achieving high-quality devices.

Detailed

Fabrication Techniques for Compound Semiconductors

The fabrication of compound semiconductors is a complex process that emphasizes control over atomic composition, crystal quality, and layer thickness to achieve superior electrical and optical properties, especially when compared to traditional silicon methods. Unlike silicon, which can utilize established fabrication techniques, compound semiconductors often require specialized epitaxial growth techniques, enabling the customization of material properties layer by layer.

This chapter provides an in-depth overview of core fabrication methods including:

1. Substrate Preparation - Establishing a clean and suitable base for growth.

2. Epitaxial Growth of active/buffer layers - The most crucial step defining device performance.

3. Lithography and etching - Defining patterns on the material.

4. Doping and Metallization - Introducing impurities for enhancing conductivity.

5. Passivation and Packaging - Finalizing the device to ensure stability and performance.

Key epitaxial techniques include:

- MOCVD (Metal-Organic Chemical Vapor Deposition) - Known for high throughput and precise composition control, ideal for high-volume production.

- MBE (Molecular Beam Epitaxy) - Offers atomic-level precision, suitable for research but with lower throughput.

- Other methods such as HVPE and LPE cater to specific applications like substrate growth for high-powered devices.

The importance of choosing the right substrate to minimize lattice mismatch and maintain high quality growth, along with appropriate doping techniques and the cleanroom environment, are also crucial elements discussed. The chapter concludes with challenges in the fabrication process and emerging techniques that offer potential advancements in compound semiconductor technology.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Introduction to Compound Semiconductors

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Fabricating compound semiconductors requires precise control over atomic composition, crystal quality, and layer thickness. This is essential to achieve the desired electrical and optical properties in advanced devices. Unlike silicon, compound semiconductors are often grown using epitaxial techniques, which allow engineers to tailor material properties through layer-by-layer deposition on a substrate. This chapter introduces the core fabrication methods used for compound semiconductors, with an emphasis on epitaxial growth techniques, and discusses their advantages, limitations, and applications.

Detailed Explanation

In the fabrication of compound semiconductors, careful control over several factors is crucial. Atomic composition refers to the specific mix of elements used, while crystal quality relates to the arrangement of atoms in the material. Layer thickness is also vital because it impacts how the semiconductor behaves electrically and optically. Unlike silicon, a common semiconductor, compound semiconductors, such as Gallium Arsenide (GaAs) or Gallium Nitride (GaN), use epitaxial growth. This means that additional material is added in thin layers on top of a substrate, allowing for customization of properties. The section highlights the importance of the fabrication techniques that will be discussed, focusing on their benefits, drawbacks, and specific uses in devices.

Examples & Analogies

Think of compound semiconductor fabrication like making a layered cake. Each layer must be perfectly balanced in ingredients (atomic composition) to achieve the right texture (crystal quality) and appearance (layer thickness). Just as the quality of the layers in a cake affects the final taste and presentation, the quality of the layers in semiconductors determines how well they function in electronic devices.

Steps in Compound Semiconductor Device Fabrication

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Compound semiconductor device fabrication generally involves: 1. Substrate Preparation 2. Epitaxial Growth of active and buffer layers 3. Lithography and Etching 4. Doping and Metallization 5. Passivation and Packaging Among these steps, epitaxial growth is the most critical for defining device performance.

Detailed Explanation

The fabrication of compound semiconductor devices consists of several key steps. The first step, substrate preparation, involves cleaning and preparing the base material. Next comes epitaxial growth, which is the most crucial phase where layers are deposited to create the active components of the device. Lithography and etching follow, where patterns are created on the semiconductor material to define circuit elements. Doping and metallization introduce impurities into the semiconductor to modify its electrical properties and add metal contacts. Finally, passivation and packaging protect the device from environmental damage. Each of these steps is vital, but the epitaxial growth process is particularly important, as it directly affects the overall performance of the semiconductor device.

Examples & Analogies

Consider making a high-performance sandwich. First, you must select the right bread (substrate preparation) and then carefully layer your ingredients (epitaxial growth). After that, you might want to cut it in a specific shape (lithography and etching). Adding condiments (doping and metallization) enhances flavor, while wrapping it securely (passivation and packaging) ensures it stays fresh. Just like the quality of each element in your sandwich affects the overall taste, each fabrication step is important for achieving a high-quality compound semiconductor device.

Epitaxial Growth Techniques Overview

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

This section introduces core epitaxial growth techniques, including MOCVD (Metal-Organic Chemical Vapor Deposition) and MBE (Molecular Beam Epitaxy), which are crucial for compound semiconductor fabrication.

Detailed Explanation

Epitaxial growth techniques are specialized methods used to deposit thin films of material on a substrate. MOCVD is a widely used technique that involves the use of metal-organic precursors, which decompose at high temperatures to form thin films on heated substrates. This method allows for high throughput and precise control over composition, making it ideal for applications like LEDs and laser diodes. On the other hand, MBE uses ultra-pure elemental sources evaporated under ultra-high vacuum conditions. This method provides atomic-level precision but is generally slower and more expensive. Each technique has its advantages and limitations which make them suited for different applications in compound semiconductor devices.

Examples & Analogies

You can think of MOCVD and MBE like two different cooking techniques: MOCVD is like frying, where you can cook many pieces of food quickly (high throughput), while MBE resembles baking, requiring more time and precision to create perfect cakes (atomic-level precision). Just like choosing the right cooking method affects the quality of the food, selecting the right epitaxial growth technique influences the properties of semiconductors.

Challenges in Compound Semiconductor Fabrication

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Challenges arise in growing high-quality compound semiconductor films, including thermal expansion mismatch and the use of toxic precursors that require rigorous safety protocols.

Detailed Explanation

Growing high-quality compound semiconductor films isn't without its challenges. One major issue is thermal expansion mismatch – different materials expand at different rates when heated, which can lead to cracking or other defects in the material. Additionally, many of the materials and chemicals used in this process, like arsine and phosphine, are toxic, necessitating strict safety measures to protect workers and the environment. This combination of physical and safety challenges requires careful planning and enhancement of the fabrication process to ensure high-quality outputs.

Examples & Analogies

Imagine you are trying to bake a cake with ingredients that expand differently when heated – if the flour expands faster than the eggs, the cake might crack. Similarly, in semiconductor fabrication, if different materials expand at different rates, it can lead to defects. Furthermore, if you had to use dangerous ingredients like hot peppers, you would need to take extra precautions while cooking. This analogy helps illustrate the delicate balance of managing materials while ensuring safety in the semiconductor fabrication process.

Key Concepts

-

Epitaxial Growth: A crucial growth technique defining semiconductor quality and performance.

-

Substrate Matching: The importance of selecting substrates to minimize defects and dislocations.

-

Doping Techniques: Methods such as ion implantation and diffusion used to enhance conductivity.

Examples & Applications

MOCVD is often used for fabricating LEDs due to its ability to precisely control the composition of materials.

MBE is preferred in research settings where atomic-level precision is necessary for experimental devices.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

MOCVD's high, through the heat it flies, precision in chemical, watch quality rise.

Stories

Imagine MBE like a sculptor, carving layers atom by atom, creating masterpieces one precise brush at a time.

Memory Tools

Remember 'DEFT' for key doping methods: 'D' for Diffusion, 'E' for Epitaxial growth, 'F' for Ion Implantation, 'T' for Thermal treatment.

Acronyms

SABLE - Substrates Are Better Layered for epitaxy!

Flash Cards

Glossary

- Compound Semiconductors

Materials composed of two or more elements that have semiconductor properties, such as Gallium Arsenide (GaAs) and Indium Phosphide (InP).

- Epitaxial Growth

A method of depositing layers of material on a substrate wherein the deposited layer has a specific crystallographic relationship with the substrate.

- MOCVD

A growth process in which metal-organic chemicals are used to deposit thin films on a substrate, primarily for creating compound semiconductors.

- MBE

An epitaxial technique that involves the evaporation of elemental sources in an ultra-high vacuum environment to form thin films.

- Lattice Mismatch

The difference in lattice constants between a substrate and a film that can lead to defects in the material being grown.

Reference links

Supplementary resources to enhance your learning experience.