MOCVD (Metal-Organic Chemical Vapor Deposition)

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to MOCVD

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're going to discuss MOCVD, which stands for Metal-Organic Chemical Vapor Deposition. Can anyone tell me what they think it involves?

I think it has something to do with chemical reactions and growth of materials?

Exactly, Student_1! MOCVD involves using metal-organic precursors that decompose at high temperatures to grow thin films on substrates. This process is critical for compound semiconductors like GaN and GaAs.

What are some of the materials we can use with MOCVD?

Great question! MOCVD supports materials like GaAs, GaN, and InP. Remember this with the acronym GGI - GaAs, GaN, InP!

Advantages of MOCVD

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now that we understand what MOCVD is, let’s talk about why it’s so advantageous. What do you think are some benefits?

I heard it has high throughput?

That's right, Student_3! MOCVD allows for high throughput, making it scalable for mass production. This is crucial for meeting the demands of the electronic market.

And the precise control over composition?

Yes, precisely, Student_4! MOCVD enables precise control over material composition, which is essential for applications requiring ternary and quaternary alloys.

Limitations of MOCVD

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

While MOCVD has many advantages, it also has its limitations. Can anyone think of one?

It requires high temperatures?

Correct! MOCVD operates at high temperatures, typically ranging from 600 to 1100 degrees Celsius. This can limit the types of substrates we can use.

Are there safety concerns as well because of toxic gases?

Exactly, Student_2! MOCVD uses toxic and pyrophoric gases, which necessitate rigorous safety protocols. Understanding these challenges is essential for working in a MOCVD environment.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Metal-Organic Chemical Vapor Deposition (MOCVD) is a significant technique used in the fabrication of compound semiconductors. It involves the decomposition of metal-organic precursors at high temperatures, allowing for precise composition control and high throughput, making it particularly useful for devices like LEDs and laser diodes.

Detailed

Detailed Summary of MOCVD

MOCVD, or Metal-Organic Chemical Vapor Deposition, is a widely employed technique in the field of semiconductor fabrication. It plays a pivotal role in the growth of compound semiconductors, such as GaAs and GaN. The process involves the decomposition of metal-organic precursors, such as Trimethylgallium and Arsine, at elevated temperatures within a specialized reactor. The thin films produced grow through controlled surface chemical reactions on heated substrates, offering several advantages:

- High Throughput: MOCVD can be scaled for mass production, making it suitable for industrial applications.

- Precise Composition Control: It allows engineers to tailor the material properties effectively, especially for ternary and quaternary alloy compositions.

- Wide Applications: The technique is ideal for various optoelectronic devices like light-emitting diodes (LEDs), laser diodes, and high electron mobility transistors (HEMTs).

However, MOCVD does come with limitations, including the need for high temperatures (approximately 600–1100°C) and the handling of toxic and pyrophoric gases. Despite these challenges, MOCVD remains a cornerstone technique within the semiconductor industry due to its capability to produce high-quality materials essential for advanced electronic and optoelectronic devices.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Working Principle of MOCVD

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Metal-organic precursors (e.g., Trimethylgallium, Arsine) are decomposed at high temperature in a reactor.

Thin films grow via surface chemical reactions on heated substrates.

Detailed Explanation

MOCVD, or Metal-Organic Chemical Vapor Deposition, involves the use of specific chemical compounds called metal-organic precursors. When these precursors, such as Trimethylgallium and Arsine, are placed in a reactor and subjected to high temperatures, they break down into their constituent elements. As this occurs, the elements react on the surface of a heated substrate to form thin films of compound semiconductors. The process relies heavily on surface chemical reactions, meaning that the conditions within the reactor must be carefully controlled to ensure uniform and high-quality film growth.

Examples & Analogies

Think of MOCVD like baking a cake. Just as you need the right ingredients (flour, sugar, eggs) that react when mixed and heated, MOCVD uses specific chemical precursors that decompose and react to create a thin layer of semiconducting material. The reactor is akin to an oven where conditions (temperature) must be just right for the best 'cake' or in this case, the semiconductor layer.

Materials Supported by MOCVD

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

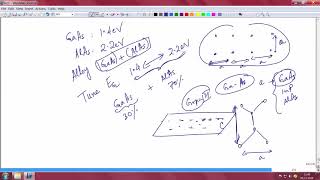

Materials Supported: GaAs, GaN, InP, AlGaAs, InGaN

Detailed Explanation

MOCVD is capable of producing a variety of compound semiconductor materials. Some of the primary materials that can be grown using this technique include Gallium Arsenide (GaAs), Gallium Nitride (GaN), Indium Phosphide (InP), and alloys such as Aluminum Gallium Arsenide (AlGaAs) and Indium Gallium Nitride (InGaN). Each of these materials has distinct electrical and optical properties which make them suitable for specific applications, particularly in optoelectronic devices such as light-emitting diodes (LEDs) and laser diodes.

Examples & Analogies

Imagine MOCVD as a multi-ingredient cooking process, where you can create various dishes (semiconductor materials) like pasta (GaAs), salad (GaN), and cake (InP) by mixing and matching different ingredients. Each dish has its unique flavor and quality just like how each semiconductor material has its unique electronic properties useful in various applications.

Advantages of MOCVD

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Advantages:

- High throughput (scalable for mass production)

- Precise control over composition (suitable for ternary/quaternary alloys)

- Ideal for LEDs, laser diodes, and HEMTs

Detailed Explanation

MOCVD comes with several advantages that make it a preferred choice for semiconductor fabrication. First, its high throughput means that it can be scaled for mass production, allowing manufacturers to produce large volumes of devices efficiently. Second, it offers precise control over the materials' composition, making it suitable for creating complex alloys (tertiary or quaternary). Lastly, MOCVD is particularly advantageous for applications requiring specific optical properties, as seen in light-emitting diodes (LEDs) and laser diodes, as well as in high-electron-mobility transistors (HEMTs).

Examples & Analogies

Think of a factory assembly line that can produce thousands of identical toys at once (high throughput), ensuring that every toy has the exact right color and size (precise control). This is similar to how MOCVD produces semiconductor materials with very specific properties needed for advanced electronic devices like LED lights or laser systems.

Limitations of MOCVD

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Limitations:

- High temperature (~600–1100°C)

- Toxic and pyrophoric gases

Detailed Explanation

While MOCVD has many benefits, it also has notable limitations. One of the primary challenges is the requirement for high growth temperatures, typically between 600 to 1100 degrees Celsius. This can lead to complications in terms of material stability and may restrict the types of substrates that can be used. Additionally, the process involves handling toxic and pyrophoric gases, which necessitates stringent safety protocols in the manufacturing environment to prevent hazardous situations.

Examples & Analogies

Imagine cooking on a very hot stove; while it allows you to sear food perfectly, it also means you need to be very careful about burns or fires (toxic gases). Just like you need good safety measures in a kitchen, MOCVD also demands rigorous safety practices because of the high temperatures and dangerous chemicals involved.

Key Concepts

-

High Throughput: MOCVD is efficient for mass production of semiconductors.

-

Chemical Reactions: Utilizes metal-organic precursors that decompose to grow semiconductor layers.

-

Material Control: Allows precise control over the composition of the materials used in semiconductor fabrication.

Examples & Applications

MOCVD is used to produce thin films of GaN, which are essential for blue LEDs and laser diodes.

In the production of high-speed electronic devices, MOCVD enables the growth of high-quality heterostructures.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

In MOCVD, thin films we see, growing from precursors, that's the key!

Stories

Once in a lab, scientists used a magical furnace where metal-organic compounds danced and transformed into brilliant semiconductors!

Memory Tools

Remember MOCVD with 'Many Organic Compounds Yield Devices'.

Acronyms

MOCVD - Metal-Organic Chemical Vapor Deposition.

Flash Cards

Glossary

- MOCVD

Metal-Organic Chemical Vapor Deposition, a technique for growing thin films of semiconductors.

- Precursor

A compound that participates in a chemical reaction to produce another compound, used in MOCVD for material growth.

- Epitaxial Layer

A layer of crystalline material deposited on a crystalline substrate to produce a structure with controlled properties.

- Ternary Alloy

A mixture made up of three components, often used in semiconductor materials to tailor properties.

Reference links

Supplementary resources to enhance your learning experience.