Fabrication Challenges

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Thermal Expansion Mismatch

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we'll discuss one of the critical challenges in compound semiconductor fabrication—thermal expansion mismatch. Can anyone tell me what this means?

Does it mean when two materials expand differently when heated?

Exactly! When the materials expand at different rates, it could lead to stress in the films. What do you think could happen due to this stress?

Maybe they could crack or peel off?

Correct! That's called cracking or delamination. To help remember, think about how a cookie cracks when baked unevenly. What do you think engineers can do to mitigate this issue?

Could they use buffer layers or select materials with similar expansion rates?

Yes! Excellent point! Now, let’s summarize: thermal expansion mismatch can cause stress and cracking, and using buffer layers can help.

Toxic Precursors

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Another challenge is the use of toxic precursors like arsenic gas. Why do you think that’s a concern?

Because they can be harmful or even deadly if inhaled?

Precisely! Because of that risk, we have to implement strict safety protocols when handling these gases. Can anyone recall one safety measure that might be employed?

Wearing protective gear and working in well-ventilated areas?

Exactly! Safety first! To help remember, consider 'Precaution Saves Lives'—keep this in mind when thinking about toxic materials! Now, let’s wrap up. Toxic precursors require strict safety measures.

Substrate Costs

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

The final challenge we'll cover today is the cost of substrates. Why do you think compound substrates are more expensive than silicon?

Maybe because they are harder to produce or less common?

Great observation! The production processes for compound semiconductors are more complex, which drives up costs. How do you think this affects the industry?

It might make it harder for companies to switch to these materials if they're too expensive.

Absolutely! It can impact the overall adoption of these technologies. One way to remember the economic aspect is the acronym 'COST': Complicated Operations Require Significant Time. Let’s summarize: higher substrate costs can hinder widespread use of compound semiconductors.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

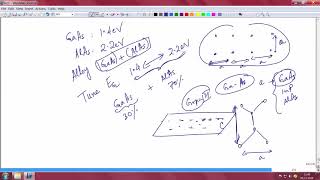

The fabrication of compound semiconductors faces several challenges including the mismatch in thermal expansion that can lead to film cracking and delamination, the necessity of safety protocols due to toxic materials like Arsine and phosphine, and the higher costs associated with compound substrates compared to silicon.

Detailed

Fabrication Challenges in Compound Semiconductors

The fabrication of compound semiconductors, while capable of yielding high-performance devices, is fraught with challenges that can adversely affect final product quality. Key challenges include:

- Thermal Expansion Mismatch: Different materials expand at different rates when heated. This mismatch can cause internal stresses leading to potentially damaging outcomes like cracking or delamination of the thin films.

- Toxic Precursors: The use of materials such as arsine (AsH₃) and phosphine (PH₃) introduces safety concerns due to their toxic nature. Stringent safety protocols must be observed during their handling and use in the fabrication process.

- Substrate Cost: Compared to traditional silicon substrates, compound semiconductors are significantly more expensive, which raises concerns for large-scale production and economic viability.

Addressing these challenges is critical for advancing the technology and improving the manufacturability of devices utilizing compound semiconductors.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Thermal Expansion Mismatch

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Thermal Expansion Mismatch: Can cause cracking or delamination.

Detailed Explanation

Thermal expansion mismatch occurs when different materials expand at different rates when heated. In semiconductor fabrication, if the substrate and the layers of semiconductor material have different thermal expansion coefficients, this can lead to stress within the material. As the material heats up during processing, one part might expand more than the other, resulting in cracking or separating from the substrate (a process known as delamination). Understanding and managing this mismatch is crucial to ensuring the structural integrity of the semiconductor materials.

Examples & Analogies

Think about two different types of metal rods that you join together to make a frame for a structure. If both metals have different expansion properties and a heat source is applied, one may lengthen significantly more than the other, causing the joint to weaken or even break. This is similar to what happens with semiconductor materials during the fabrication process.

Toxic Precursors

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Toxic Precursors: Arsine (AsH₃), phosphine (PH₃) require rigorous safety protocols.

Detailed Explanation

In semiconductor fabrication, particularly in the growth of compound semiconductors, toxic gases like arsine (AsH₃) and phosphine (PH₃) are often used as precursors. These gases are essential for incorporating specific elements into the semiconductor layers. However, due to their toxic nature, safe handling protocols must be strictly followed. This includes utilizing specialized equipment, training personnel, and ensuring proper ventilation to prevent accidents or exposure. The need for rigorous safety measures complicates the fabrication process and adds to the overall cost.

Examples & Analogies

Imagine working in a laboratory where you need to handle dangerous chemicals. Just as you would wear gloves, goggles, and a mask to protect yourself, semiconductor facilities must implement extensive safety systems to handle toxic gases safely. It's similar to how some kitchens have strict protocols when using sharp knives or hot surfaces to ensure everyone's safety while cooking.

Substrate Cost

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Substrate Cost: Compound substrates are more expensive than silicon.

Detailed Explanation

Substrates are the foundational materials on which semiconductor layers are built. In the context of compound semiconductors, the substrates (like GaAs or InP) are generally more expensive than traditional silicon substrates. The higher cost is due to the more complex and less common materials used, which can affect the overall price of the final semiconductor devices. This cost factor presents a significant challenge, especially for scaling up production and making these devices economically viable for a broader market.

Examples & Analogies

Consider the difference in price between using a regular glass cooking dish and a specialized non-stick ceramic dish for baking. The ceramic dish, while potentially better for cooking certain recipes, costs significantly more. In the same way, while compound semiconductor substrates may provide superior performance, their higher costs can limit their use compared to more affordable silicon alternatives.

Key Concepts

-

Thermal Expansion Mismatch: This refers to the discrepancy in thermal expansion rates between different materials during temperature changes, which can lead to structural defects.

-

Toxic Precursors: These are hazardous substances that necessitate rigorous safety measures during handling and processing in semiconductor fabrication.

-

Substrate Cost: The expense associated with materials used as substrates in fabricating semiconductor devices, influencing viability and scaling production.

Examples & Applications

Thermal mismatch can cause a GaN layer on sapphire to crack during cooling.

High production costs can deter manufacturers from using InP substrates despite their performance benefits.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

When materials expand, they've got to withstand, keep them matched, or cracking is planned.

Stories

Imagine two friends trying to share a seat. One is big and expands the seat, while the other is small. If both are not compatible, the friendship (the layer) cracks!

Memory Tools

Think 'CAT' for remembering challenges: C for Cost, A for Arsenic worries, T for Thermal mismatch.

Acronyms

CST for remembering the challenges

for Costly substrate

for Safety with toxic materials

for Thermal expansion.

Flash Cards

Glossary

- Thermal Expansion Mismatch

The phenomenon where different materials expand at different rates when subjected to temperature changes, potentially causing stress and defects.

- Toxic Precursors

Chemical substances used in semiconductor fabrication that are hazardous to health, requiring stringent safety protocols.

- Substrate Cost

The financial expense associated with the materials used as base layers for semiconductor devices, which can significantly impact manufacturing costs.

Reference links

Supplementary resources to enhance your learning experience.