Field Compaction Methods

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Field Compaction Methods

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we’re discussing field compaction methods, which are vital for ensuring our structures have the necessary strength and stability. Can anyone tell me why compaction is important?

It helps increase the density of the soil, right?

Exactly! Higher density means better load-bearing capacity. Do you know any methods used for compaction?

I think there are different types of rollers. What are they?

Great question! We have smooth wheel rollers, pneumatic rollers, vibratory rollers, and sheep-foot rollers. Let's explore these methods in detail.

Types of Rollers

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s dive deeper into types of rollers. Who can explain what a vibratory roller does?

It uses vibration to compact the soil, making it effective for granular materials.

Correct! And what about sheep-foot rollers? What makes them unique?

They have feet that penetrate the soil, which helps compact cohesive soils.

Well explained! Remember, selecting the right roller is crucial depending on the soil type and project requirements.

Compaction Monitoring Techniques

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Monitoring is vital in compaction to ensure effectiveness. Who can name one technique?

The nuclear density gauge?

Yes! It rapidly measures density and moisture. Can anyone tell me an alternative method?

The sand cone method is another traditional way to check density?

Exactly right! Each method has advantages, but monitoring ensures we meet compaction standards. What is the typical compaction percentage we aim for?

95-100% of the laboratory maximum dry density?

Exactly! This is critical depending on layer requirements and expected traffic loads.

Significance of Proper Compaction

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Why do we need such precision with compaction? What affect does poor compaction have?

It could lead to pavement failure or uneven settling.

Right! Poor compaction can result in an unstable subgrade and reduce the durability of our infrastructure. In what ways can we ensure effective compaction?

Using the right equipment and monitoring with techniques like nuclear density gauges.

Correct! Continuous monitoring and selecting appropriate methods are key components of quality assurance in pavement engineering.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section discusses the different types of field compaction methods used in construction, particularly focusing on rollers and monitoring equipment like nuclear density gauges and sand cone tests to ensure proper soil density and stability.

Detailed

Field Compaction Methods

Field compaction is a crucial process in construction and pavement engineering, ensuring the stability and strength of the ground beneath structures. Various methods are used to compact soil effectively, focusing primarily on different types of rollers:

- Types of Rollers:

- Smooth Wheel Rollers: Best for compacting granular soils.

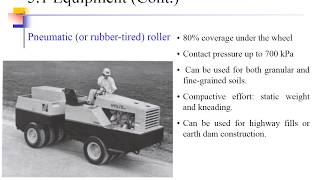

- Pneumatic Rollers: Suitable for layers of soil that require flexibility in compaction.

- Vibratory Rollers: Utilize vibration to enhance compaction, ideal for granular soils and asphalt pavements.

- Sheep-Foot Rollers: Equipped with feet that penetrate the soil, making them particularly effective for cohesive soils.

- Monitoring Compaction: Ensuring the effectiveness of compaction is vital. There are two primary methods for monitoring:

- Nuclear Density Gauge: Provides rapid results by measuring the density and moisture content of the soil.

- Sand Cone Method: A more traditional technique that involves determining the volume of a hole after excavation and calculating density based on the weight of the sand used to fill it.

- Significance: Proper field compaction methods and monitoring are critical for achieving the desired density (typically 95-100% of the laboratory maximum dry density) required for different soil types and traffic loads. These practices enhance the durability and longevity of pavement structures.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Types of Rollers

Chapter 1 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Rollers: Smooth wheel, pneumatic, vibratory, sheep-foot

Detailed Explanation

The text mentions different types of rollers used for soil compaction. Each roller has a unique design and purpose:

Examples & Analogies

Think about how different tools are used in a workshop. Just like a hammer is used for nails and a screwdriver for screws, different types of rollers are designed for specific soil conditions. For example, a sheep-foot roller is great for clay, while a smooth wheel roller is best for asphalt.

Compaction Monitoring Techniques

Chapter 2 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Compaction monitored using nuclear density gauge or sand cone method

Detailed Explanation

The section discusses two primary methods for monitoring compaction in the field. The nuclear density gauge uses radioactive isotopes to measure the density of the soil, while the sand cone method involves filling a hole dug in the soil with sand to determine its density. These measurements help ensure that the soil has been compacted adequately.

Examples & Analogies

Imagine checking the firmness of a cake. Just as you might use a toothpick to check if a cake is done baking, engineers use these tools to confirm that the soil is compacted to the right density.

Key Concepts

-

Field Compaction: The process of increasing soil density through mechanical means to support structures.

-

Rollers: Different types of machines used to compact soil, each suited for specific conditions.

-

Monitoring Techniques: Tools like nuclear density gauges and sand cone methods to ensure proper compaction.

-

Compaction Standards: Aim to achieve 95-100% of laboratory maximum dry density for effective soil strength.

Examples & Applications

Smooth wheel rollers are typically used for asphalt applications due to their ability to create a smooth surface.

Vibratory rollers are often effective on granular soils as the vibrations enhance particle rearrangement and density.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

To make the ground strong and firm, roll it with a vibratory squirm.

Stories

Once upon a time, in a construction yard, there lived a smooth wheel roller who loved to dance on asphalt. He teamed up with a sheep-foot roller who knew how to give a good push, helping them compact the soil perfectly for buildings that stood tall and proud.

Memory Tools

Remember the 4 R's for Rollers: Rigid, Robust, Rapid, and Reliable for soil compaction.

Acronyms

R-CAM

Rollers

Compaction Techniques

And Monitoring methods.

Flash Cards

Glossary

- Compaction

The process of densifying soil by expelling air to increase its density and strength.

- Rollers

Heavy machinery used in compaction, including smooth wheel, pneumatic, vibratory, and sheep-foot rollers.

- Nuclear Density Gauge

A device that measures the density and moisture content of soil through nuclear radiation.

- Sand Cone Method

A method for measuring the in-place density of soil by filling a hole with sand and calculating volume based on displacement.

Reference links

Supplementary resources to enhance your learning experience.