Resilient Modulus (Mr)

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Resilient Modulus

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we are diving into the Resilient Modulus, often denoted as Mr. Can anyone tell me why it's important in pavement design?

Is it because it helps us understand how soil behaves under repeated loads?

Exactly! Mr helps us assess the elastic response of soil to those loads. Remember that it is defined as the ratio of repeated axial stress to recoverable strain. Can someone repeat that definition for me?

"It's the ratio of stress to strain, right?

Mathematical Representation and Use

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now that we've covered the definition, let’s analyze how to calculate Mr. The formula is: M_r = σ / εᵣ. What do you think the implications are?

More stress leads to a higher modulus if the strain recovers, which seems crucial for our pavement design.

Spot on! The recoverable strain indicates how elastic the soil is under repeated load. Why does this matter for pavements?

If the soil is more elastic, it can better handle traffic loads without deforming.

Exactly! By using Mr, we can predict performance and adjust our designs accordingly.

Practical Application of Resilient Modulus

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Can anyone think of ways we might apply Mr in real-world pavement design?

I guess when designing roads, we choose materials based on their Mr values?

That's right! Engineers will select subgrade materials according to their resilience to optimize the pavement's lifespan. What else could influence the decision?

Traffic load, environmental conditions, and local soil types!

Exactly! Those factors, combined with Mr, help determine the design and composition of pavement layers.

Difference Between CBR and Mr

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's compare Mr with CBR. Who can explain the core differences?

CBR is a static measure of strength, while Mr focuses on dynamic response under repeated loads.

Exactly! And why might Mr be a better indicator for pavement design?

Because it's more realistic — it reflects how soils behave in actual traffic conditions!

Correct! Using Mr allows for more accurate and efficient designs.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The Resilient Modulus (Mr) represents the ratio of repeated axial stress to recoverable strain in soil. This parameter plays a critical role in mechanistic pavement design and is a more accurate indicator of real-life soil performance compared to tests such as the California Bearing Ratio (CBR). Understanding Mr is essential for evaluating soil's ability to support pavement structures under traffic loads.

Detailed

Resilient Modulus (Mr)

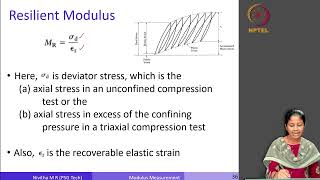

The Resilient Modulus (Mr) is defined as the ratio of repeated axial stress (C3) to the recoverable strain (B5) in a soil material, expressed mathematically as:

$$ M_r = \frac{\sigma}{\epsilon_r} $$

This property is crucial in the field of pavement engineering as it provides insights into how well soil can respond elastically to repeated loads, such as those imposed by vehicular traffic. Unlike the California Bearing Ratio (CBR), which provides a static measure of strength, the Resilient Modulus is more representative of actual field conditions and dynamic loading scenarios. Therefore, it is often employed in mechanistic pavement design to forecast performance and design suitable pavement structures.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Definition of Resilient Modulus

Chapter 1 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The resilient modulus (Mr) is defined as the ratio of repeated axial stress to recoverable strain:

$$M_r = \frac{\sigma}{\epsilon_r}$$

Detailed Explanation

The resilient modulus is a key parameter in understanding how soils behave under repeated loading, which is commonly found in pavement applications. It represents the stress applied to the soil and how much the soil reversibly deforms (or strains) under that stress. In this equation, σ (sigma) represents the repeated axial stress applied to the soil, while ε (epsilon_r) represents the recoverable strain that occurs from that applied stress. In simpler terms, the resilient modulus indicates how well soil can return to its original shape after the load is removed.

Examples & Analogies

Imagine a good quality rubber band. When you stretch it (applying stress), it elongates (deforming). Once you release it, it goes back to its original shape (recoverable strain). The resiliency of the rubber band is like the resilient modulus; it describes how well the soil can return to its original form after being compressed or stressed by vehicles.

Importance of Resilient Modulus

Chapter 2 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The resilient modulus is crucial in mechanistic pavement design and is considered a better indicator of real-life performance than the California Bearing Ratio (CBR).

Detailed Explanation

The resilient modulus plays a significant role in mechanistic pavement design, which focuses on the physical properties of materials and their responses to stress. It provides engineers with a more accurate representation of how pavements will behave in real-life situations compared to traditional tests like the California Bearing Ratio (CBR). While CBR gives a baseline on the load-bearing capacity of subgrade materials, the resilient modulus takes into account the repeated loading conditions that pavements typically experience, making it a more reliable parameter for evaluating pavement performance.

Examples & Analogies

Think of resilient modulus as the test of a good running shoe. While the shoe's thickness and sole material (analogous to CBR) tell you something about its support, only real runs (analogous to resilient modulus) reveal how well the shoe will perform under the repetitive stress of running on different surfaces. The shoe's ability to absorb impact and return to shape is like the soil's ability to handle repetitive loads.

Key Concepts

-

Resilient Modulus (Mr): A crucial parameter for evaluating how soils respond under repeated loads, serving as a basis for mechanistic pavement design.

-

California Bearing Ratio (CBR): A traditional strength measure for soil, often considered less accurate than Mr for predicting performance in real-world scenarios.

Examples & Applications

In pavement design, if a soil exhibits a high Resilient Modulus, it suggests that it can endure heavy traffic loads without significant deformation, leading to longer-lasting roads.

In contrast, a soil with a low Resilient Modulus may undergo excessive deformation under traffic loads, necessitating additional treatments to enhance its properties.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Mr keeps our roads in line, elastic strength is quite divine.

Stories

Imagine a road built on a soft sponge. Every time a car drives over, it sinks in, but once the weight is off, it bounces back. Just like our Resilient Modulus, this sponge shows how our soils should ideally react!

Memory Tools

For Remembering Mr: M = R = S / E; Modulus means Resilient, Stress on Earth.

Acronyms

Mr = Mighty Resilient - holds up the roads we drive!

Flash Cards

Glossary

- Resilient Modulus (Mr)

A measure of a soil’s elastic response to repeated loading, defined as the ratio of repeated axial stress to recoverable strain.

- California Bearing Ratio (CBR)

A measure of strength of subgrade soil based on the penetration resistance of soil.

Reference links

Supplementary resources to enhance your learning experience.