Dynamic Viscosity Correlations

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Understanding Shear Stress and Shear Strain Rate

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s start with shear stress and shear strain rate. Can anyone tell me how these two concepts are related in fluid mechanics?

Shear stress is the force per unit area acting parallel to the surface.

Exactly! And shear strain rate describes how quickly layers of fluid slide past each other. Now, according to Newton’s law of viscosity, what do we know about the relationship between them?

Shear stress is proportional to the shear strain rate.

Correct! We can summarize that with the equation: shear stress (τ) = dynamic viscosity (μ) times the shear strain rate (du/dy). Remember the acronym VSS - 'Viscosity is Shear Stress proportional'.

Impact of Temperature on Viscosity

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, how does temperature affect viscosity in liquids versus gases?

In liquids, increasing temperature decreases viscosity.

But in gases, increasing temperature increases viscosity!

Exactly! As temperature rises, the intermolecular forces weaken in liquids, leading to lower viscosity. For gases, the increased kinetic energy leads to more random movement, increasing viscosity. Use the phrase TCL - 'Temperature Changes Liquids'.

Newtonian vs Non-Newtonian Fluids

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s differentiate between Newtonian and non-Newtonian fluids. Who can define them?

Newtonian fluids have a constant viscosity irrespective of the shear rate.

Non-Newtonian fluids have variable viscosity depending on the rate of deformation.

Great job! Remember the acronym NTT - 'Newtonian is Time-independent, Non-Newtonian is Time-dependent'. Can anyone give an example of a non-Newtonian fluid?

Toothpaste is a good example—it thickens under shear.

Very good! We can categorize non-Newtonian fluids further like pseudoplastic and dilatant.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The section delves into how dynamic viscosity varies with temperature and pressure, the differentiation between Newtonian and non-Newtonian fluids, and the relevance of shear stress and strain rate. It introduces key concepts like the Sutherland correlation and explores how viscosity behaves across different types of fluids.

Detailed

Dynamic Viscosity Correlations

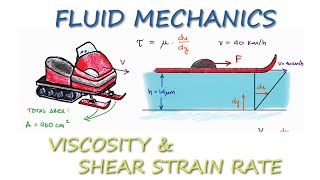

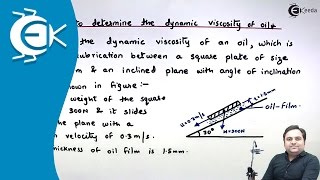

This section focuses on dynamic viscosity in fluid mechanics, especially through the analysis of shear stress and shear strain rates. In a scenario where fluid flows between two parallel plates, with one stationary and the other moving at a velocity V, the fluid experiences linear velocity variations. This linear relationship leads to angular deformations in the fluid element over time, highlighting how velocity gradients relate to shear strains.

Key Concepts:

- Newton's Laws of Viscosity: Shear stress is directly proportional to the shear strain rate, emphasizing the difference between fluid and solid mechanics.

- Impact of Temperature: An increase in temperature typically decreases viscosity in liquids due to weaker intermolecular forces, while gases exhibit an increase in viscosity with temperature rise.

- Sutherland Correlation: A specific equation that correlates dynamic viscosity with temperature for gases, encompassing specific constant values for different fluids.

- Newtonian vs Non-Newtonian Fluids: Newtonian fluids maintain a constant viscosity regardless of shear rates, while non-Newtonian fluids exhibit variable viscosity based on shear forces, categorized further into pseudoplastics, dilatants, and Bingham plastics.

In summary, the section thoroughly examines viscosity's behavior under varying conditions, establishing fundamental principles necessary for understanding fluid dynamics.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Fluid Flow Visualization

Chapter 1 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

If I consider the same fluid flow through a parallel plate, okay. One of the plate the velocity is zero which is at the rest conditions and other the top plate is moving with a velocity V. So as a microscopic point of view I am not talking about the molecular motions or exchange of the molecular motions or the momentum flux that what is resulting a shear stress. Here what we consider that fluid element. That means, I consider some space of A, B, C, D, this is what the fluid element. That means, whatever the fluids are there that reasons, I am defined as a fluid element. As you know it that at the A point we will have the velocity V as the no-slip conditions. At the B point we will have velocity zero.

Detailed Explanation

This chunk describes a fluid flowing between two parallel plates. One plate does not move (zero velocity), and the other moves at velocity V. The fluid elements between these plates behave differently based on their position. For instance, the fluid at the moving plate (point A) has a velocity of V, while fluid at the stationary plate (point B) remains at zero velocity. This creates a velocity gradient between the two points, crucial for understanding shear stress in the fluid.

Examples & Analogies

Imagine a row of children on a slide. The child at the top is sliding down quickly (point A), while the child at the very bottom (point B) is at a complete standstill. The space between them represents varying speeds and interactions in the fluid.

Linear Velocity Distribution

Chapter 2 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

So velocity assuming it, it will have a linear velocity variation from B to A. That linear velocity from zero to V as the y increases, the velocity will increase it and maximum velocity will be the V. If it that the conditions now if you look it that if a point which is the y distance from the plate which is at the rest conditions you will have velocity U, okay. So as a linear proportionally we can find out what is the velocity of that one.

Detailed Explanation

The concept of linear velocity distribution is introduced. As the distance from the stationary plate increases (moving vertically up through the fluid), the velocity of the fluid also increases linearly from zero to V. This relationship can be visualized as a linear graph where the y-axis represents fluid velocity and the x-axis represents distance from the stationary plate.

Examples & Analogies

Think of a highway where cars gradually speed up as they approach the entrance ramp. The closer cars are to the ramp (point A), the faster they're moving, while cars waiting at a red light (point B) aren't moving at all. The gradual speed increase is similar to how fluid velocity changes between two plates.

Shear Stress and Angular Deformations

Chapter 3 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

If as a linear velocity distribution as you assume it as we got it some of the parallel flow conditions after ∆t time these fluid element will be deformed as a angular deformations will happen it that there will be angle θ will come it at the B and E, F and D. That is a new positions of the fluid element after ∆t time. And the angular deformations at this point is θ.

Detailed Explanation

As time progresses, the initially positioned fluid elements (A, B, C, D) will undergo deformation because of the motion of the upper plate. This deformation can create angular displacements (θ), leading to a change in the orientation of the fluid elements. This aspect highlights how fluid elements do not just slide; they also twist and turn under shear stress.

Examples & Analogies

Picture a soft plastic sheet being pulled at one end. The closer the top edge (the moving end) gets to the fixed bottom edge, the more it bends and twists. Similarly, the fluid elements adjust their positions based on the shear forces acting on them.

Shear Rate and Dynamic Viscosity

Chapter 4 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The shear rate strain rate and the velocity gradient is equal for these conditions. Then the shear rate is ∂u/∂y. These parallel flow conditions when you have velocity is linear distributions the shear strain rate and the velocity gradient they are equal.

Detailed Explanation

In this section, the relationship between shear rate, strain rate, and velocity gradients in fluid flow is discussed. Under linear flow conditions, the shear rate (how quickly the fluid is deforming) is directly proportional to the velocity gradient (difference in velocity over a distance). This relationship is key to understanding the behavior of fluids under shear.

Examples & Analogies

Imagine squeezing a tube of toothpaste. The faster you push (the shear rate), the more the toothpaste moves. The change in motion relative to how far you push it (the velocity gradient) helps us determine how much force is needed to squeeze the paste out.

Newton's Law of Viscosity

Chapter 5 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The stress having the proportionality with the strain. But here, we are talking about the stress is proportionality to the strain rate. That means the change of the shear strain rate with respect to time, not the absolute value of the shear strain.

Detailed Explanation

Newton’s law of viscosity states that shear stress is proportional to the shear strain rate over time, which means that stress in a fluid due to shear is directly related to how quickly it deforms. This equation implies that fluids behave differently than solids — the relationship is not based on static deformation.

Examples & Analogies

Think of how honey pours compared to water. If you gently tilt the honey container, it flows slowly (high viscosity), whereas water rushes out quickly (low viscosity). The stress applied (tilting the container) leads to different strain responses due to the fluids' viscosities.

Temperature and Dynamic Viscosity

Chapter 6 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Now let us commit that how does the temperature effect on the coefficient of the viscosity. Now we have to look at the molecular levels okay. So if you look at this molecular levels, when you talk about the liquids, they will have a molecular bonding forces between two molecules okay. But that is much weaker when talk about the gases. So gas is at more random motions as compared to the molecules are more random motion as compared to the liquids.

Detailed Explanation

Temperature affects viscosity significantly at the molecular level. In liquids, attractions between molecules (bonding forces) are stronger than in gases. As temperature increases, the energy given to molecules results in greater motion, disrupting these bonds for liquids (lowering viscosity), while in gases, it increases randomness (affecting viscosity differently). Understanding this relationship helps predict fluid behavior under different thermal conditions.

Examples & Analogies

Consider how syrup thickens in the fridge but flows freely at room temperature. As the syrup warms, molecular motion increases, making it less viscous and easier to pour. Conversely, cold temperatures can significantly decrease fluid flow, making it sluggish and thick.

Key Concepts

-

Newton's Laws of Viscosity: Shear stress is directly proportional to the shear strain rate, emphasizing the difference between fluid and solid mechanics.

-

Impact of Temperature: An increase in temperature typically decreases viscosity in liquids due to weaker intermolecular forces, while gases exhibit an increase in viscosity with temperature rise.

-

Sutherland Correlation: A specific equation that correlates dynamic viscosity with temperature for gases, encompassing specific constant values for different fluids.

-

Newtonian vs Non-Newtonian Fluids: Newtonian fluids maintain a constant viscosity regardless of shear rates, while non-Newtonian fluids exhibit variable viscosity based on shear forces, categorized further into pseudoplastics, dilatants, and Bingham plastics.

-

In summary, the section thoroughly examines viscosity's behavior under varying conditions, establishing fundamental principles necessary for understanding fluid dynamics.

Examples & Applications

When heating honey, its viscosity decreases, making it flow more easily.

When heating air, the viscosity increases due to more vigorous molecular movement.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Viscosity low, let it flow, heating it up, watch it go!

Stories

Imagine a viscous stream; as it heats, it thins while flowing like a dream.

Memory Tools

ST for Strength in Temperature: Sutherland correlation.

Acronyms

VSS - Viscosity is Shear Stress proportional.

Flash Cards

Glossary

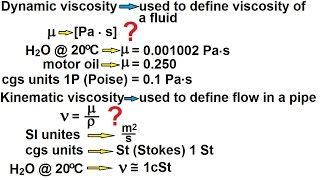

- Dynamic Viscosity

A measure of a fluid's resistance to flow or deformation.

- Shear Stress

The force acting parallel to a surface per unit area.

- Shear Strain Rate

The rate at which adjacent layers of fluid slide past one another.

- Newtonian Fluids

Fluids whose viscosity does not change with the rate of shear strain.

- NonNewtonian Fluids

Fluids that have a viscosity that changes with the rate of shear strain.

Reference links

Supplementary resources to enhance your learning experience.