Newton’s Laws of Viscosity

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Fluid Flow

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we will explore how fluids behave when they flow between two parallel plates. Imagine one plate is stationary while the other moves. What do you think happens to the fluid in between?

I think the fluid closer to the moving plate will move faster than the one near the stationary plate.

Exactly! That's called a velocity gradient. As we move away from the stationary plate toward the moving one, the fluid's velocity increases linearly. Can anyone explain what we mean by 'linear' here?

It means that the velocity increases consistently without any sudden changes!

Perfect! Now, remember this as we discuss shear stress, which is related to these velocities.

Shear Stress and Shear Strain Rate

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s talk about shear stress and shear strain rate. Who can tell me how they're related?

Isn't shear stress proportional to the velocity gradient?

Yes! The equation is τ = μ (du/dy). Here, τ represents the shear stress, μ is the viscosity, and (du/dy) is the velocity gradient. Can someone expand on what viscosity represents?

Viscosity measures the internal friction of the fluid, right? It shows how resistant a fluid is to flow.

Exactly! And this relationship defines Newtonian fluids. Viscosity remains constant across the shear rate for these fluids. Let's remember to differentiate between this and non-Newtonian fluids later!

Difference Between Solid and Fluid Mechanics

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let's compare fluid mechanics to solid mechanics. How is shear stress treated differently in fluids compared to solids?

In solids, shear stress relates to the amount of deformation, while in fluids, it relates to how quickly the fluid is deforming, right?

Exactly! In fluid mechanics, shear stress is proportional to the shear strain rate rather than the absolute strain. Why do we think this distinction is important?

It helps us understand fluid behaviors in various applications, like in pipes or when painting!

Exactly! Different behaviors mean different engineering approaches.

Viscosity and Temperature Effects

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, let’s examine how temperature influences viscosity. What happens to viscosity as we heat a liquid?

I think it decreases because the molecules move faster and have less intermolecular attraction.

Right on! That's why heating oil can reduce its viscosity. In contrast, what happens with gases as we increase temperature?

For gases, viscosity actually increases because the increased thermal energy leads to more collision between molecules.

Correct! Understanding these differences helps us manage fluids in industries, like refining processes.

Newtonian vs. Non-Newtonian Fluids

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's wrap up by discussing Newtonian and non-Newtonian fluids. Who can give me an example of each?

Water is a Newtonian fluid, and ketchup is a non-Newtonian fluid!

Great examples! Newtonian fluids have a constant viscosity, while non-Newtonian fluids' viscosity changes with the rate of shear. Why is this distinction critical in engineering?

Because it affects how we design systems to handle different fluids!

Exactly! Knowing how these fluids behave allows for better designs and practical applications.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The section delves into the behavior of fluids under shear stress, particularly in parallel plate flow, illustrating how velocity gradients are related to shear strain rates. It also highlights the crucial distinction between solid mechanics and fluid mechanics, emphasizing that shear stress in fluids is proportional to shear strain rate, which is a defining feature of Newtonian fluids.

Detailed

Newton’s Laws of Viscosity

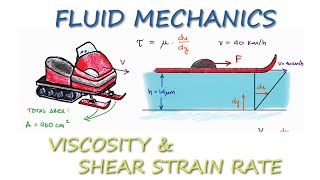

This section introduces the fundamental principles behind Newton’s laws of viscosity, focusing on fluid flow between two parallel plates. When one plate is stationary and the other moves with a velocity V, an interesting phenomenon arises: a linear velocity gradient develops from rest to the moving plate. As the distance from the stationary plate increases, the fluid's velocity increases proportionally until it reaches the moving plate's velocity.

The key mathematical relationship derived here is the direct proportionality between shear stress and shear strain rate, characterized by the equation:

τ = μ (du/dy)

where τ represents shear stress, μ is the dynamic viscosity, and (du/dy) denotes the velocity gradient perpendicular to the flow direction.

A crucial differentiation is made between the concepts within fluid mechanics and solid mechanics, as the shear stress in fluids correlates to shear strain rate (a change over time), rather than absolute strain as in solids. This section also discusses how viscosity varies with temperature and pressure, examining experimental findings that illustrate how these factors influence fluid properties.

Finally, a profile of different fluid types is introduced, including Newtonian and non-Newtonian fluids, categorized based on their responses to shear forces. The nuanced behavior of these fluids in response to changes in viscosity highlights the complexity of fluid behavior and the significance of Newton’s laws of viscosity.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Concept of Fluid Flow Between Plates

Chapter 1 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

If I consider the same fluid flow through a parallel plate. One of the plates has velocity zero (at rest) and the other top plate is moving with a velocity V. As we consider this from a microscopic point of view, we focus on fluid elements defined by points A, B, C, D. At point A, we have velocity V (due to no-slip condition), while at point B, we have velocity zero. Therefore, the velocity varies linearly from B to A, with maximum velocity V.

Detailed Explanation

This chunk introduces the basic setup of fluid flow between two parallel plates. One plate is stationary, while the other moves, creating a velocity gradient. The no-slip condition states that fluid in contact with a stationary plate must have zero velocity. As we move from the stationary plate (point B) to the moving plate (point A), the fluid's velocity increases linearly. Understanding this setup is crucial as it lays the foundation for discussing shear stress and viscosity.

Examples & Analogies

Imagine spreading butter on bread. The knife (moving plate) moves across the butter (fluid), and the bottom layer of butter stays still due to the bread (stationary plate). The butter closest to the knife moves faster than the layer in contact with the bread, illustrating the linear velocity distribution.

Angular Deformations of Fluid Elements

Chapter 2 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

After a short time, these fluid elements will deform, leading to angular deformations. At position B and points E, F and D, similar angular deformations occur, which we denote as θ. Over short time intervals Δt, the rate of angular deformation can be related to the flow characteristics.

Detailed Explanation

As fluid moves between the plates, it doesn't just slide but also deforms angularly. This deformation is essential because it relates to how the fluid exhibits shear stress. The angle θ represents a small deformation related to the flow velocity and time. Analyzing these angular changes helps us understand how fluids respond to forces, which is critical in fluid mechanics.

Examples & Analogies

Think of a rubber band. When you stretch it (apply a shear force), it deforms. After releasing it, the band changes shape, showing its angular deformation. Similarly, fluid elements experience deformation due to shear stress in a flow scenario.

Shear Strain Rate and Velocity Gradient

Chapter 3 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

If I consider the y-direction and the angular velocity distributions, I can calculate the velocities at these points (u) and the ratio of the distances. From the relationship established, we see that the velocity gradient corresponds to the rate of shear strain.

Detailed Explanation

The velocity gradient is crucial in defining how shear strain rate is calculated. It measures how quickly the velocity changes over distance (y-direction). In fluid mechanics, this relationship signifies how the fluid reacts under stress. A higher velocity gradient implies that the fluid is more susceptible to deformation, relating directly to the shear stress applied.

Examples & Analogies

Imagine you have a thick syrup. If you tilt the container, the syrup flows slowly at the bottom and faster on top. The difference in velocity is like the velocity gradient — the steeper the incline (or more force applied), the quicker the syrup flows.

Newton’s Law of Viscosity

Chapter 4 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The rate of change of shear strain rate is proportional to the shear stress applied. This relationship defines Newton's law of viscosity where shear stress is proportional to the shear strain rate, not to the absolute shear strain, marking a key distinction between fluid mechanics and solid mechanics.

Detailed Explanation

Newton's law of viscosity establishes that shear stress (τ) is directly proportional to the shear strain rate (du/dy), where μ (dynamic viscosity) is the proportionality constant. This means when you apply shear stress to a fluid, its deformation rate increases proportionally, differing from solids, where stress relates to strain. This foundational principle governs fluid behavior under stress.

Examples & Analogies

Think about honey compared to water. When you push each, honey flows slowly and requires more force (higher viscosity) than water. This difference in response under the same stress illustrates Newton’s viscosity law: the thicker the fluid, the more resistance it has to flow.

Effect of Temperature on Viscosity

Chapter 5 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

When discussing the effects of temperature on viscosity, it is observed that with increasing temperatures, the kinetic energy of the fluid molecules increases, leading to reduced viscosity for liquids due to weakened intermolecular forces. In gases, the trend is the opposite and viscosity tends to increase with temperature.

Detailed Explanation

The relationship between temperature and viscosity is critical in understanding fluid behavior. For liquids, increased temperature reduces viscosity because molecules move more rapidly and are less held together by intermolecular forces. Conversely, in gases, increased temperature leads to increased molecular movement, thereby increasing viscosity as more collisions occur among gas molecules.

Examples & Analogies

Consider cooking syrup. As you heat it, the syrup becomes thinner and easier to pour (lower viscosity). Conversely, imagine a gas at high temperatures like steam. As temperature rises, steam can become more difficult to compress, hence increasing its viscosity.

Key Concepts

-

Shear Stress (τ): The pressure experienced by a fluid layer due to forces acting tangentially.

-

Dynamic Viscosity (μ): A constant that represents a fluid's resistance to shear, crucial for determining flow behavior.

-

Velocity Gradient (du/dy): An essential factor determining how fluid velocity changes with respect to distance.

-

Newtonian Fluids: Fluids that showcase a linear relationship between shear stress and shear rate.

-

Non-Newtonian Fluids: Fluids with complex flow properties where shear stress does not have a direct linear relationship with shear rate.

Examples & Applications

Water is an excellent example of a Newtonian fluid where shear stress is directly proportional to the shear rate.

Ketchup, which behaves as a non-Newtonian fluid, requires a certain force to start flowing (yield stress) and can thin out as shear rate increases.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Viscosity tells how thick or thin, Under stress, flow lets in.

Stories

Imagine a river flowing; some is thick mud while others are smooth pebbles. The mud represents a high viscosity, while the pebbles represent low viscosity fluid, illustrating how different flows experience shear stress.

Memory Tools

SHED - Shear Stress, Hydrostatic pressure, Elastic modulus, Dynamic viscosity help remember the key fluid mechanics terms.

Acronyms

VASE - Viscosity And Shear Effects, to remember that viscosity is crucial in understanding shear effects in fluids.

Flash Cards

Glossary

- Shear Stress (τ)

The force per unit area exerted by a fluid parallel to the plane of interest.

- Dynamic Viscosity (μ)

The property of a fluid that measures its resistance to flow and deformation.

- Velocity Gradient (du/dy)

The change in velocity with respect to distance from a stationary plate in fluid flow.

- Newtonian Fluid

A fluid whose viscosity remains constant regardless of the shear rate.

- NonNewtonian Fluid

A fluid whose viscosity changes with the shear rate, exhibiting complex flow behavior.

Reference links

Supplementary resources to enhance your learning experience.