Continuity Equations

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Understanding Velocity Defects

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we will discuss the concept of velocity defects in high turbulence flows. Can someone tell me why understanding velocity defects is important?

I think it helps us understand how an actual velocity compares to the average velocity.

Exactly! Velocity defects show us the deviations in flow, necessary for analyzing turbulent flows. Remember, we can use the acronym V for Velocity, D for Deviation - V and D to recall the relationship!

What does the velocity defect mean in practical terms?

Great question! It indicates how much the local velocity differs from the average. Understanding this helps in designing systems that minimize energy loss.

So, how do we measure these deviations?

We use empirical data, like experimental findings from Nikuradse, to determine factors that help us calculate these defects accurately. Let's summarize: Velocity defects help us analyze deviations which are critical in turbulent flow design.

Energy Losses in Pipes

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s talk about energy losses in pipes. Can anyone explain what major and minor losses refer to?

I think major losses are due to friction, while minor losses happen due to fittings and changes in the pipe diameter?

Correct! Major losses predominantly arise from friction along the length of the pipes. Minor losses include factors like bends, expansions, and contractions. When calculating the total energy loss in a system, we need to add them together.

Do these losses affect the discharge through pipes?

Yes, they do! In series pipes, the sum of the energy losses will determine how much flow can be sustained. Remember, the total discharge remains constant through the system; however, energy losses change based on the configuration.

So, we must consider both types of losses in our calculations?

Absolutely! Always remember to compute both major and minor losses to understand the actual performance of your pipe system.

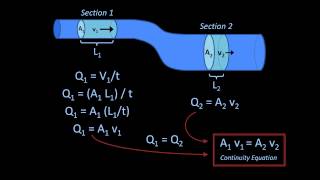

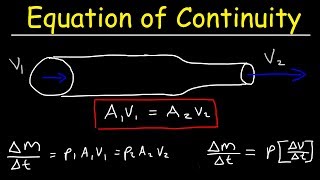

Continuity Equations in Series and Parallel Pipes

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s discuss how continuity equations work in series and parallel pipes. Who can define a continuity equation?

The continuity equation states that the mass flow rate must remain constant from one section of a pipe to another.

Great! In series pipes, this means that the discharge remains the same across various sections despite energy losses. Can someone explain about parallel pipes?

In parallel pipes, the discharge divides among the branches but the head losses should still be equal at each branch.

Exactly! Energy losses need to be balanced, and we can use this principle to compute how flow divides through each pipe. The acronym PACE can help: P for Parallel, A for All, C for must be equal, E for energy losses.

If energy losses are equal, does that mean each branch can have different diameters?

Yes! The diameters can vary, but the sum of the discharges through each path will equal the main flow, in line with continuity principles.

So, both series and parallel systems are about balancing flow and energy?

Precisely! Balancing flow and energy is key in fluid dynamics design.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

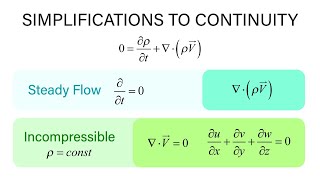

The section covers continuity equations regarding fluid flow, explaining the concepts of velocity defects in turbulent flows, energy losses in pipe systems, and examples of pipes in series and parallel configurations. Key equations and empirical findings related to flow dynamics are also discussed.

Detailed

Detailed Summary

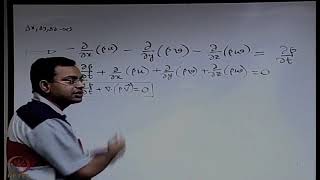

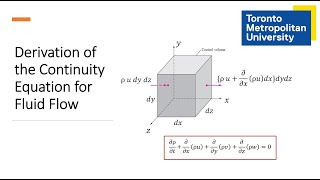

In fluid dynamics, continuity equations represent the principle of mass conservation in flowing fluids. This section delves into various aspects, such as velocity defects, where the flow velocity deviates from the average velocity, leading to critical implications in high turbulence conditions. The relationship between friction factors, fluid velocity, and energy losses in pipelines is elucidated through dimensional analysis, referencing significant empirical data like Nikuradse experiments.

Pipes are analyzed in both series and parallel configurations, where the overall flow behavior must satisfy the principles of continuity. The section emphasizes that the discharge (Q) must remain constant for pipes in series despite energy losses due to friction. Students are introduced to equations that define energy loss, exploring both minor and major losses throughout the system.

Specific scenarios are illustrated with detailed examples, such as junction problems involving multiple reservoir systems, leading to practical calculations based on head losses and gradient lines. The conclusion of the section reinforces the necessity of balancing energy losses with potential energy to maintain desired flow rates. Overall, understanding these principles is critical for effective fluid system design and analysis.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Velocity Defect Concept

Chapter 1 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

But if you go to the outer layers where we look it that a velocity defect concept, how far the velocity from average velocity, that the defect means how much deviations how much difference between that.

Detailed Explanation

The velocity defect concept refers to the difference between the actual velocity of fluid at a point in a flow stream and the average velocity of the fluid. This difference, or defect, indicates how much the velocity deviates from the average due to influences such as friction and turbulence. In fluid dynamics, the analysis of these variations is crucial for understanding flow characteristics, especially in turbulent flows where velocity can fluctuate significantly.

Examples & Analogies

Think of sitting in a car on a highway. While the car is supposed to travel at an average speed of 60 mph, if it goes up a hill, the speed might drop to 50 mph due to the incline, creating a 'velocity defect'. This is similar to fluid flow where obstacles or changes in the medium (like bends or rough surfaces) can cause deviations from the average speed.

Turbulent Flow and Velocity Measurements

Chapter 2 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Now if you look it that, if you put it high turbulence flow and the velocity the reasons is very this is called velocity deflect law...

Detailed Explanation

In turbulent flow conditions, the fluctuations become more pronounced, and this results in more significant velocity defects. The equation related to turbulent flow incorporates parameters like the pipe radius (h), average velocity, and shear velocity, which help measure the flow velocity and its variations. A common formula involves a logarithmic relationship between velocity and distance from the pipe wall, reflecting how flow characteristics change within turbulent regimes.

Examples & Analogies

Imagine a highway during a rush hour where cars are moving at different speeds due to congestion and road conditions. Just like measuring the speeds of different cars can give insight into the overall traffic flow, analyzing the various velocities in turbulent fluid flow can help predict and manage flow behavior in engineering applications.

Head Loss in Pipes

Chapter 3 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

If you have definitely the discharge will be for a steady state conditions for steady flow conditions...

Detailed Explanation

In a system with pipes arranged in series, the discharge remains constant across each pipe due to the continuity equation. However, losses can occur due to friction (major losses) and changes in pipe diameter (minor losses). It's essential to sum up all head losses to understand the total energy expenditure in the system, which influences flow capacity.

Examples & Analogies

Consider a long water slide. If the slide is smooth (low friction), water will flow fast; but if it has rough patches, the water will slow down due to energy losses (head loss). Just like the excitement of sliding can change with bumps, the flow in pipes can be affected by friction and pipe geometry.

Pipes in Parallel

Chapter 4 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

When you have a pipe in parallel, you can understand it see if I have the pipe in the parallels...

Detailed Explanation

In parallel piping systems, the combined flow paths must maintain equal energy loss for each path. When water splits to flow through multiple pipes, the principles of conservation of mass and energy dictate that flow rates will change based on pipe characteristics. This is crucial for designing efficient piping systems that manage the flow effectively through various routes.

Examples & Analogies

Think of parallel pipes as different paths a group of friends can take to reach a coffee shop. Each friend may take different routes, but they all must arrive together at the same time. Similarly, in a piping system, the water must flow through different pipes yet ensure equal energy losses.

Three Reservoir Junction Problems

Chapter 5 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Now if you look it the three reservoir junction problems which many of the time it is given...

Detailed Explanation

The three reservoir junction problem involves analyzing flow at a junction where multiple water paths converge. The flow capacities of inlets and outlets at the junction must balance out so that mass flow is conserved. Using continuity equations helps determine how much water can flow in and out without causing disruptions in the system.

Examples & Analogies

Imagine three rivers merging at a point. If one river is flowing more slowly than the others, it may cause flooding or drought in some areas. Engineers apply continuous equations to ensure balanced flow without disruption, similar to how a river confluence must maintain a natural flow.

Key Concepts

-

Continuity Equation: Assures mass conservation in flowing fluids.

-

Velocity Defect: Indicates local velocity variations from the average in turbulent flows.

-

Head Loss: Represents energy loss in the system due to friction.

-

Series and Parallel Systems: Different configurations affecting energy distributions and flow balancing.

Examples & Applications

In a system of pipes arranged in series, the discharge will remain constant despite varying energy losses along each pipe segment.

For parallel pipes, if one pipe experiences more friction, the overall flow will still balance out ensuring that energy losses remain equivalent across all paths.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Velocity defects deviate, bringing flows that hesitate.

Stories

Imagine a river with twists; as it flows, it struggles with friction and turns, learning balance along its path.

Memory Tools

VDC for understanding Flow: V for Velocity, D for Defect, C for Continuity.

Acronyms

P.A.C.E for Pipe Flow

for Parallel

for All

for must be equal

for energy losses.

Flash Cards

Glossary

- Continuity Equation

A mathematical expression that describes the transport of some quantity, such as mass or energy in a fluid flows, establishing that mass and energy must be conserved.

- Velocity Defect

The difference between the average velocity and the actual local velocity in a turbulent flow.

- Head Loss

The loss of energy due to friction and turbulence in a fluid system, measured as a height of fluid.

- Minor Losses

Energy losses associated with fittings, bends, and transitions in pipes.

- Major Losses

Energy losses primarily due to friction as fluid flows through the length of a pipe.

Reference links

Supplementary resources to enhance your learning experience.