Friction Losses and Energy Gradients

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Friction Losses

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're going to learn about friction losses in pipes. Can anybody tell me why these losses matter in fluid flow?

They affect how much pressure and energy is available for the fluid to move.

"That's correct! Friction losses reduce the energy of the fluid, which is crucial for ensuring efficient flow.

Energy Gradients in Pipe Flow

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now that we know about friction losses, let’s talk about energy gradients. Who can explain what an energy gradient is?

Isn’t it how energy decreases along the flow of the fluid?

"Yes! It’s crucial for understanding pressure changes in fluid systems.

Practical Application: Pipe Systems

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s apply what we've learned to some practical examples! Can anyone describe a simple pipe network system?

How about a series of pipes leading from a water tank to a house?

Great example! In this case, we would calculate the total head losses along the series. How do we do that?

By adding the head losses from each individual pipe!

Correct! And what about if we had pipes in parallel?

We would set the energy losses to be equal across all paths, right?

Exactly! A mnemonic for this is 'Equal losses, equal paths.' Let’s summarize: Calculating these losses is vital in ensuring an adequate flow in our systems.

Losses and Energy Gradients in Reservoir Junctions

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now we'll discuss three reservoir junction problems. What can you tell me about how flow behaves at junctions?

Flows coming in have to equal the flows going out, to conserve mass.

Absolutely! Conservation is key here. To visualize it: 'What goes in, must come out!' Now, how does head loss factor into this scenario?

We need to calculate the head loss to know the pressure at the junction.

Precisely! And we can use our previous calculations for major and minor losses to determine this. Let's work through a sample problem together.

So head losses will determine how much flow we get at each outlet?

Exactly! Remember, hydrodynamics isn’t just about pipes. Flow at junctions is equally vital. Summarizing: Analyze head loss to understand flow distributions.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

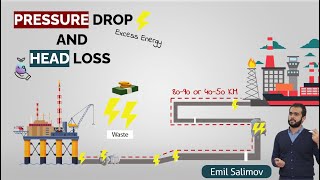

In this section, we explore how friction losses affect energy gradients in fluid systems, emphasizing the significance of understanding these losses in pipe networks, such as in series and parallel flow scenarios. We also cover head loss due to both major and minor losses, applying practical examples.

Detailed

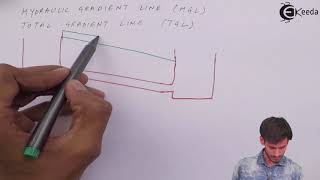

Friction Losses and Energy Gradients

This section delves into the essential concepts of friction losses and energy gradients encountered in fluid flow through pipes. Friction losses arise from the resistance encountered by fluid as it moves through a pipe, significantly affecting the energy available for flow and system performance. The primary focus is on how these losses manifest in both major (due to friction along the pipe surfaces) and minor (due to factors like fittings and bends) categories.

Key Concepts Covered:

- Velocity Defect Concept: The introduction of velocity defect concepts where deviations from average velocity are examined.

- Friction Losses in Pipe Systems: Exploration of how energy losses are calculated in systems with pipes in series or parallel, where total head loss is determined by summing individual losses.

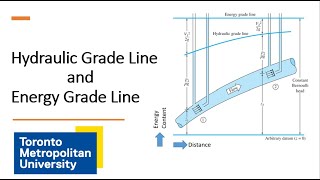

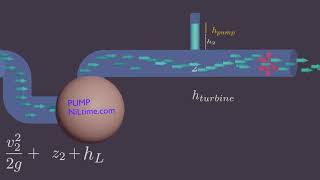

- Energy Gradient: The energy gradient line represents how energy is distributed within a system, particularly at junctions of pipe networks consisting of multiple reservoirs.

- Applications: Practical applications of these principles, such as determining flow rates in pipes and understanding the losses that influence the dynamics of fluid transport systems.

Understanding these concepts is critical in civil engineering and hydraulic studies, as they underpin the design and analysis of fluid systems in real-world applications such as water supply, wastewater treatment, and other hydraulic structures.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Understanding Velocity Defect Concept

Chapter 1 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

But if you go to the outer layers where we look it that a velocity defect concept, how far the velocity from average velocity, that the defect means how much deviations how much difference between that.

Detailed Explanation

This section introduces the velocity defect concept in fluid dynamics, specifically in turbulent flows. The velocity defect refers to the difference between the actual velocity of the fluid and the average velocity. Understanding this defect is crucial for analyzing flow behavior and predicting how fluid moves within a given system.

Examples & Analogies

Imagine a group of people walking in a park. If everyone's average speed is 5 km/h but some individuals are moving faster or slower than that, their speed differences represent the velocity defect. Studying these variances helps to determine how smoothly the entire group moves.

Dimensional Analysis and Velocity Defects

Chapter 2 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

We again we get the similar functions from the dimensional analysis between V and y and h.

Detailed Explanation

Dimensional analysis is a technique used to understand the relationships between different physical quantities. In this case, it shows how velocity (V) relates to vertical distance (y) and head (h). This relationship can help define how energy losses relate to flow dynamics.

Examples & Analogies

Consider baking a cake. You have specific proportions of ingredients that create a balanced cake. Similarly, dimensional analysis helps ensure the flow rates and head losses are balanced within a fluid system.

Turbulence Flow and Alpha Constants

Chapter 3 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Now if you look it that, if you put it high turbulence flow and the velocity the reasons is very this is called velocity deflect law and h is replaced by the R the pipe radius.

Detailed Explanation

In high turbulence flows, specific constants (like alpha) play a significant role in determining how energy losses occur. For turbulent flow conditions, it’s crucial to replace head with pipe radius when calculating velocity fluctuations. This adjustment allows for accurate predictions of how turbulent flows behave within pipes.

Examples & Analogies

Think of a stormy river with lots of waves and whirlpools. The behavior of water in this chaos is similar to high turbulent flow in pipes, where understanding characteristics like pipe radius can help engineers design better drainage systems.

Major and Minor Losses in Pipe Flow

Chapter 4 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

But when you have a pipe in a series please remember it that you always should consider whether there is a minor losses. There is major losses which is the frictional losses component for the pipe 1.

Detailed Explanation

In pipe systems, there are two types of losses to consider: major losses, which are primarily due to friction as fluid flows through pipes, and minor losses, which arise from various fittings like valves or bends. Understanding both is crucial for accurate calculations of energy losses in fluid systems.

Examples & Analogies

Consider water flowing through a garden hose. The friction of the water against the walls of the hose (major loss) is significant, but if there are kinks or bends in the hose, they add to the loss as well (minor losses). Knowing both helps you optimize watering efficiency.

Energy Losses in Series and Parallel Pipes

Chapter 5 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

If you have definitely the discharge will be for a steady state conditions for steady flow conditions. So discharge at the Q1, Q2, Q3 that should be equal because this is a steady state.

Detailed Explanation

In fluid flow systems, particularly in series and parallel pipes, the discharge must remain consistent in steady-state conditions. This principle means that the sum of all discharges must be the same throughout the system, aiding in accurate calculations for energy losses across multiple paths.

Examples & Analogies

Imagine a multi-lane highway where cars merge and split. Even if some lanes are wider (more discharge), the total number of cars (discharge) reaching each exit point must remain equal to prevent traffic backups.

Three Reservoir Junction Problems

Chapter 6 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Now if you look it the three reservoir junction problems which many of the time it is given that you have a multiple reservoirs.

Detailed Explanation

When dealing with multiple reservoirs connected through pipes, understanding how flow out of each reservoir affects the overall system is complex. The flow conservation principle states that the total discharge should equal the discharge at the junction point, helping calculate energy losses between the reservoirs.

Examples & Analogies

Think of three tanks connected at a crossroads. The water level will equalize based on how much water is drawn from each. Understanding this flow can prevent any one tank from overflowing or running dry.

Practical Example: Energy Loss in Pipe Flow

Chapter 7 of 7

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

An incompressible fluid flowing through a steady rate in a horizontal pipe, okay. From a section, pipe is divided into two horizontal pipes as given the d1 and d2.

Detailed Explanation

This example illustrates a scenario of fluid dynamics in which an incompressible fluid flows through horizontal pipes. Given the diameters and lengths of the pipes, students can analyze how to calculate energy losses due to friction and derive the velocity ratio between different pipe sections.

Examples & Analogies

Imagine a water slide where two slides start at the same height but have different widths. As kids slide down, understanding how wide the slides affect their speed relates directly to analyzing flow through pipes with varying diameters.

Key Concepts

-

Velocity Defect Concept: The introduction of velocity defect concepts where deviations from average velocity are examined.

-

Friction Losses in Pipe Systems: Exploration of how energy losses are calculated in systems with pipes in series or parallel, where total head loss is determined by summing individual losses.

-

Energy Gradient: The energy gradient line represents how energy is distributed within a system, particularly at junctions of pipe networks consisting of multiple reservoirs.

-

Applications: Practical applications of these principles, such as determining flow rates in pipes and understanding the losses that influence the dynamics of fluid transport systems.

-

Understanding these concepts is critical in civil engineering and hydraulic studies, as they underpin the design and analysis of fluid systems in real-world applications such as water supply, wastewater treatment, and other hydraulic structures.

Examples & Applications

Consider a water tank connected to a long pipe; friction losses can be calculated to determine how much energy is lost to keep water flowing.

In a pipe network with multiple branches, energy gradients change based on how flow is distributed among various paths.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Friction in pipes makes flow slow, causing energy to ebb and flow.

Stories

Imagine water flowing through a forest; as it hits rough terrain (friction), it slows down, losing energy on its journey.

Memory Tools

Remember 'FRESH' for Friction, Resistance, Energy losses, Shear, and Head loss.

Acronyms

Use the acronym 'FLEMM' to recall Friction Loss, Energy gradient, Major loss, Minor loss.

Flash Cards

Glossary

- Friction Losses

Energy losses that occur due to the friction between the fluid and the pipe walls.

- Energy Gradient

A line representing the energy loss in a flowing system, indicating how energy decreases over distance.

- Minor Losses

Losses that occur due to fittings, bends, and sudden changes in geometry in a piping system.

- Major Losses

Losses primarily due to friction along the length of the pipe.

- Velocity Defect

The difference between the average velocity and actual velocity of fluid in the pipe.

- Head Loss

The loss of total mechanical energy due to friction in the fluid flow.

Reference links

Supplementary resources to enhance your learning experience.