Aggregates

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Aggregates

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're going to talk about aggregates in concrete pavements. Can anyone tell me what aggregates are?

Are they the materials mixed with cement to make concrete?

Exactly! Aggregates comprise both coarse and fine materials. Coarse aggregates are typically larger particles like crushed stone. Can anyone tell me what we look for in coarse aggregates?

They should be strong and clean, right?

Correct! Strong, angular, and clean coarse aggregates help enhance the interlocking of particles, which is crucial for pavement strength. Now, what finer aggregates do we use?

Clean river sand or manufactured sand?

Right again! Fine aggregates fill the gaps and improve workability. Remember the acronym SAF: Strong-Angular-Fine for success in aggregate selection!

That's an easy way to remember it!

Great! Let's summarize what we learned: aggregates are key components of concrete mix for pavements and come in two types; coarse and fine. They must meet shear strength and workability standards.

Importance of Grading

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s talk about grading. Why is grading important for aggregates in pavements?

It helps in finding the right balance between the coarse and fine aggregates.

Exactly! Grading prevents segregation, maximizes density, and ensures optimal packing. Can someone explain why a well-graded mix is beneficial?

It should create a stronger concrete that's less prone to cracking.

Right! A well-graded aggregate blend will reduce voids and improve structural integrity. Also, think of the mnemonic 'GLOW': Grading Leads to Optimum workability.

That's helpful!

In summary, a well-graded mix not only enhances the strength of the concrete but also its workability. Aim for GLOW in aggregate grading!

Selection Criteria for Aggregates

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

When selecting aggregates for concrete pavements, what criteria do you think we should consider?

I think we should consider strength and cleanliness.

Yes! Also, we must consider grading, shape, and size. Let’s create a mnemonic: 'SCGS': Strength, Cleanliness, Grading, Shape. Can anyone elaborate on the importance of shape?

Angular shapes provide better interlock and strength.

Exactly! Angular aggregates offer more bonding surfaces which improves overall strength. For our recap: remember SCGS when selecting aggregates!

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

In this section, we explore the role of aggregates in concrete mixes for pavements, detailing the distinct types of aggregates (coarse and fine), their qualities, and the importance of grading to ensure strength and workability in the final concrete mix.

Detailed

Aggregates in Concrete for Pavements

In the construction of concrete pavements, aggregates play a fundamental role in influencing the overall strength, durability, and workability of the concrete mix. This section outlines the two primary types of aggregates utilized: coarse aggregates, typically characterized as angular, clean, and hard crushed stones, and fine aggregates, which usually consist of clean river sand or manufactured sand that adheres to grading specifications.

Types of Aggregates

- Coarse Aggregates: These are larger particles that provide primary strength and structural integrity. To achieve optimal performance in pavement applications, they must be angular and clean to enhance interlocking and load distribution.

- Fine Aggregates: Composed of smaller particles, fine aggregates fill in the gaps between coarse aggregates, contributing to the overall density and workability of the concrete. Clean river sand, or manufactured sand meeting grading limits, is often preferred.

Grading of Aggregates

Proper grading is crucial to ensure a well-balanced mix that effectively meets performance criteria for pavement applications. Well-graded aggregates provide improved strength, adequate workability, and optimized void filling. This balance minimizes the potential for cracking and enhances the durability of the pavement, especially in environments subject to various stresses and load conditions.

The significance of aggregate selection and grading in concrete mix design cannot be overstated, as these factors collectively dictate the behavior and longevity of concrete pavements.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Coarse Aggregates

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Coarse Aggregates: Angular, hard, and clean crushed stone.

Detailed Explanation

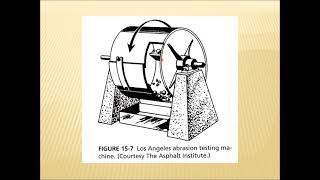

Coarse aggregates are large particles used in concrete mixtures, typically greater than 4.75 mm in size. In this context, they should be angular and hard. Angular aggregates interlock better, providing improved strength and stability to the concrete. They also need to be clean, meaning free of contaminants such as dirt and clay, which can undermine the bond with cement and reduce overall performance.

Examples & Analogies

Think of coarse aggregates like the building blocks in a wall. Just as blocks need to fit together tightly and be strong to support the wall, coarse aggregates must be hard and angular to create a solid concrete mix that can withstand heavy loads.

Fine Aggregates

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Fine Aggregates: Clean river sand or manufactured sand conforming to grading limits.

Detailed Explanation

Fine aggregates consist of smaller particles, typically smaller than 4.75 mm, which fill the spaces between coarse aggregates in concrete. They can be sourced from natural materials like river sand or manufactured products. It is crucial that these fine aggregates adhere to specific grading limits, which means they should contain a mix of particle sizes within certain limits to ensure optimal packing and workability of the concrete.

Examples & Analogies

Imagine fine aggregates as the sand in a sandcastle. Just as the right type of sand is needed to hold the structure together and prevent it from collapsing, fine aggregates in concrete help fill gaps between larger stones, creating a stronger and more stable material.

Grading of Aggregates

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Grading: Must ensure a well-graded mix for strength and workability.

Detailed Explanation

Grading refers to the distribution of different particle sizes in aggregates. A well-graded mix contains a suitable range of sizes that fill voids efficiently, contributing to both the strength and workability of the concrete. The goal is to minimize the amount of cement needed while providing a dense, strong, and workable mixture. Poorly graded aggregates can lead to an increase in voids, requiring more cement and water, which can adversely affect durability.

Examples & Analogies

Think of grading like making a fruit salad. If you only use one type of fruit, the salad isn't very appealing or tasty. However, if you combine different fruits of various textures and flavors, you get a delicious and balanced dish. Similarly, a well-graded aggregate mix provides the necessary balance for strong and durable concrete.

Key Concepts

-

Coarse Aggregates: Tend to be larger particles that provide primary strength.

-

Fine Aggregates: Smaller parts that enhance workability and density.

-

Grading: Process of optimizing aggregate sizes for strength and workability.

Examples & Applications

Example of coarse aggregates includes 20 mm crushed stones, while clean river sand would be an example of fine aggregates.

When designing a concrete mix, using a balanced blend of coarse and fine aggregates can minimize void spaces and enhance strength.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Aggregates so large and small, mix them right to stand tall.

Stories

Picture a puzzle where the pieces are coarse and fine. If they fit well, the structure will shine!

Memory Tools

Remember the SAF: Strong-Angular-Fine for selecting good aggregates!

Acronyms

GLOW

Grading Leads to Optimum workability.

Flash Cards

Glossary

- Coarse Aggregates

Larger particles such as crushed stone used in concrete for structural strength.

- Fine Aggregates

Smaller particles such as sand that fill voids in the concrete mix.

- Grading

The distribution of particle sizes within a concrete mix that affects workability and strength.

Reference links

Supplementary resources to enhance your learning experience.