Step 7: Trial Mixes and Adjustments

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Trial Mixes

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're discussing trial mixes. Can anyone explain what a trial mix is?

Isn't it a preliminary batch we create to test our design?

Exactly! Trial mixes are indeed preliminary batches used to evaluate whether the mix design meets our performance specifications. What key tests do we conduct on these trial mixes?

We test for flexural strength, workability, and durability indicators, right?

Correct! Flexural strength at 28 days and other factors like workability and air content are critical. Let’s remember this with the acronym ‘FFD’ – Flexural, Workability, and Durability tests.

That’s a good way to remember it!

Now, why do we need to adjust our mix after these tests?

To ensure our pavement can handle all the stresses like traffic and weather changes!

Precisely! Adjustments help ensure longevity and performance.

Testing for Performance Indicators

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's dive deeper into the tests we perform post-mixing. What do we mean by testing for flexural strength?

It's the measure of how much bending stress the concrete can withstand, right?

Yes! We typically use a beam specimen of specific dimensions for this. Any idea what dimensions we use?

150 mm by 150 mm by 700 mm, as per the standards.

Correct! Testing it properly is crucial since it reflects how the concrete will behave under real conditions. How long do we usually let it cure before we do the flexural tests?

28 days!

Good job! Remember, the results guide our mix adjustments. If flexural strength is too low, what might we do?

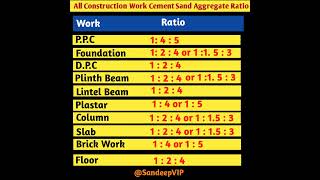

We could increase the cement content or alter the aggregate ratios.

Excellent! Adjusting these aspects can help us reach our target flexural strength.

Adjustments Based on Trial Results

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s focus on how to make adjustments. After testing a trial mix, what should we do if it doesn't meet our specifications?

We should analyze where the shortcomings are and then modify the mix proportions.

Exactly! And it’s essential to ensure that each adjustment is recorded. What could happen if we forgot to document our changes?

We'd have a hard time replicating the successful mix later!

Correct! Documentation is key in engineering practices. Remember the phrase ‘Mix it, Note it!’ to embed this habit.

That's a catchy reminder!

Great! Now, can anyone summarize the sequence of making adjustments?

Test results, analyze, adjust, and document!

Exactly! Well done!

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section describes the process of creating trial mixes for concrete pavements, highlighting the importance of testing for flexural strength, workability, and durability indicators to ensure the mix performs as intended. It emphasizes the need for adjustments based on these test results to achieve optimal concrete performance.

Detailed

In this section, the process of preparing trial mixes for concrete pavements is delineated. The aim is to achieve the required specifications pertaining to flexural strength, workability, air content, and various durability indicators such as sulfate resistance and abrasion. Each trial batch undergoes a series of tests to evaluate its performance at 28 days of curing, ensuring that the selected concrete mix conforms to the desired characteristics. If the outcomes of these tests do not align with the expectations, adjustments to mix proportions are made accordingly. This iterative approach is vital in the concrete mix design process, ensuring final concrete performance meets structural and operational demands.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Preparing Trial Batches

Chapter 1 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Prepare trial batches.

Detailed Explanation

In this step, trial batches of concrete are mixed to test the performance of the concrete mix. A trial batch is a small quantity of concrete produced to verify that the mix design meets the specified requirements for strength, workability, and other characteristics. The objective is to ensure that the designed proportions of materials produce a workable and durable concrete.

Examples & Analogies

Think of a chef who develops a new recipe. Before serving it to guests, they will create a small test batch to taste and make adjustments as needed. Just like the chef's test batch helps ensure the recipe is perfect, trial batches ensure that the concrete mix will perform well under real conditions.

Testing for Flexural Strength

Chapter 2 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Test for:

o Flexural strength at 28 days.

Detailed Explanation

Flexural strength testing measures the ability of the concrete to resist bending forces. After the trial batches have been cured for 28 days, samples are tested using a third-point loading method to determine the modulus of rupture, which is a key indicator of the concrete's performance under load. The results guide whether adjustments are needed to the mix design.

Examples & Analogies

Imagine a bridge that needs to support heavy traffic. Engineers test materials used to construct the bridge just as we test concrete; they must ensure it can withstand loads without cracking. The flexural strength test assures that the concrete will also perform reliably under such stress.

Assessing Workability

Chapter 3 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

o Workability (slump).

Detailed Explanation

Workability refers to how easily concrete can be mixed, placed, and finished. One common method to measure workability is the slump test, which determines how much a concrete sample 'slumps' when a cone mold is removed. A proper slump indicates that the concrete is workable and will not be too stiff or too loose, ensuring good placement in the pavement.

Examples & Analogies

Think of making cookie dough. If it’s too thick, you can't spread it on a baking sheet easily, and if it’s too runny, it will spread out too much. The right consistency, or workability, is crucial for making good cookies just like it is for pouring and shaping concrete.

Checking Air Content

Chapter 4 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

o Air content.

Detailed Explanation

Air content in concrete refers to the amount of air voids present in the mix, which can positively influence its durability against freeze-thaw cycles. It is important to assess air content in trial mixes to ensure that the concrete is formulated correctly for environmental conditions, particularly in regions subject to significant temperature variation.

Examples & Analogies

Consider that an insulated jacket can keep you warm by trapping air; similarly, air pockets in concrete help protect it from the harsh effects of winter. Ensuring the right amount of air content is like making sure you have enough insulation in your jacket before stepping out into the cold.

Evaluating Durability Indicators

Chapter 5 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

o Durability indicators (sulfate resistance, abrasion).

Detailed Explanation

Durability indicators are tests that help evaluate the concrete's resistance to various forms of deterioration, such as sulfate attack, which can occur in environments with high sulfate concentrations. Tests for abrasion resistance can also be performed to measure how well the concrete can guard against surface wear and tear over time. These evaluations are crucial to ensure that the concrete will have a long lifespan in its intended applications.

Examples & Analogies

Imagine a shoe designed for hiking. It needs to withstand mud and abrasion from rough trails; similarly, concrete must endure environmental wear and tear. Testing for durability indicators is like checking that your hiking shoes have the right traction and material to last for many hikes in rugged terrain.

Key Concepts

-

Trial Mix Preparation: Essential for determining optimal concrete mix.

-

Flexural Strength Testing: Crucial to evaluate bending resistance.

-

Adjustments After Testing: Necessary to align the mix with performance goals.

Examples & Applications

A trial mix with low flexural strength may need a higher cement content or a modification in aggregate proportions.

If a mix's workability is poor, increasing the water content or adding a plasticizer can improve it.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Test and adjust, don’t delay; jazz up the mix to save the day.

Stories

Imagine a baker who needs the perfect cake. They try different mixes until one is just right, documenting each try along the way. That’s how concrete mixes work too!

Memory Tools

Remember the ‘FFD’ - Flexural, Workability, Durability for trial mix testing.

Acronyms

M.I.N.D – Mix, Inspect, Note, and Decide on adjustments after trials.

Flash Cards

Glossary

- Trial Mix

A preliminary mix of concrete tested to determine performance characteristics.

- Flexural Strength

The ability of concrete to resist deformation under load.

- Workability

The ease with which concrete can be mixed, placed, and finished.

- Durability Indicators

Characteristics that evaluate the concrete's resistance to environmental factors.

- Curing

The process of maintaining adequate moisture to ensure proper hydration of concrete.

Reference links

Supplementary resources to enhance your learning experience.